Silicon and indium antimonide products and senors may soon be history with the arrival of magnetic sensors

Text: Bhushan Mhapralkar

As part of a research project, a team led by Associate Professor Yang Hyunsoo of NUS Electrical and Computer Engineering, with the support of Dr Kalon Gopinadhan, Research Fellow at NUSNNI; Professor Thirumalai Venkatesan, Director of NUSNNI; Professor Andre K Geim of the University of Manchester; and Physics Professor Antonio H Castro Neto, Director of CA2DM, have developed a magnetic sensor, which is 200 times more sensitive than most commercially available products. This means smaller and lower-cost sensors can potentially be used in areas such as consumer electronics, information and communication technology, biotechnology and automotive applications.

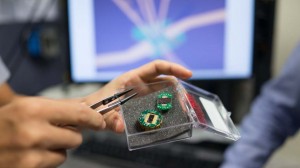

Professor Yang and his team developed the new sensor from graphene and boron nitride. Comprising a few layers of carrier-moving channels controlled by a magnetic field, the hybride sensor shows much higher sensitivity than current silicon and indium antimonide products. When measured at 127 degree Celsius, the maximum temperature which most electronics products operate at, the hybrid sensor recorded a sensitivity gain of more than eight-fold over other reported laboratory results, and more than 200 times that of sensors in the market. It also showed little temperature dependence from room temperature to 127 degree Celsius, making it ideal for hot environments. Another major discovery is that the mobility of the graphene multi layers enables the sensor’s characteristics to be optimised by tuning the voltage across it. This control gives the material an advantage over existing sensors.

Professor Yang and his team got excited that the breakthrough work of cheaper sensor production by eliminating expensive wafers is possible. Explained Professor Yang, who is also attached to the National University of Singapore’ Nanoscience and Nanotechnology Institute (NUSNNI) and the Centre for Advanced 2D Materials (CA2DM), that magnetic sensors are found in abundance. From home appliances to counters that track the number of vehicles in parking lots this can be used. “For instance, a car alone can have up to 30 magnetic sensors to monitor speed, pressure and position, as well as other functions,” he added. According to Professor Yang, the properties of the current sensors can change due to air-conditioning or heat from the sun, requiring a temperature correction mechanism which incurs more cost. This is not so in case of the magnetic sensors his team has developed. It avoids such issues, allowing for tinier and cheaper electronics. “Our sensor is perfectly poised to pose a serious challenge in the magneto-resistance market by filling the performance gaps of existing sensors, and finding applications as thermal switches, hard drives and magnetic field sensors. Our technology can even be applied to flexible applications,” exclaimed Yang. ACI