The Automotive New Product Development (NPD) ecosystem is one of the most complex environments. Suhas Kini writes how a finished automobile at the backend has manufacturers toiling away to achieve a complex and audacious end goal.

The New Product Development (NPD) comes with its share of challenges. This complexity can be attributed to factors like many parts developed by different auto component manufacturers that must not only come together in the final vehicle, but also function together flawlessly as a system. While developing auto components is important, it is equally important to deliver them through a process that is robust, precise, and repeatable at scale. Thus, while the end customer gets to see a stylish high-performance automobile, what they don’t see is the back end where numerous auto component manufacturers toil to achieve this complex and audacious goal.

A saga of skips and misses

The automotive landscape is changing. Electric Vehicles (EVs) are predicted to take over the industry – IC engines will eventually become extinct. The advent of EVs and the elimination of the IC engine, the most complex part of erstwhile vehicle design, has democratised the industry. With entry barriers being razed to the ground and new EV players entering with advanced technologies, the existing auto OEMs are feeling the heat like never before, to be the first to market in the EV segment! As a result, there is an urgency to move amongst the OEMs, from the drawing board to the market, at a faster rate than before.

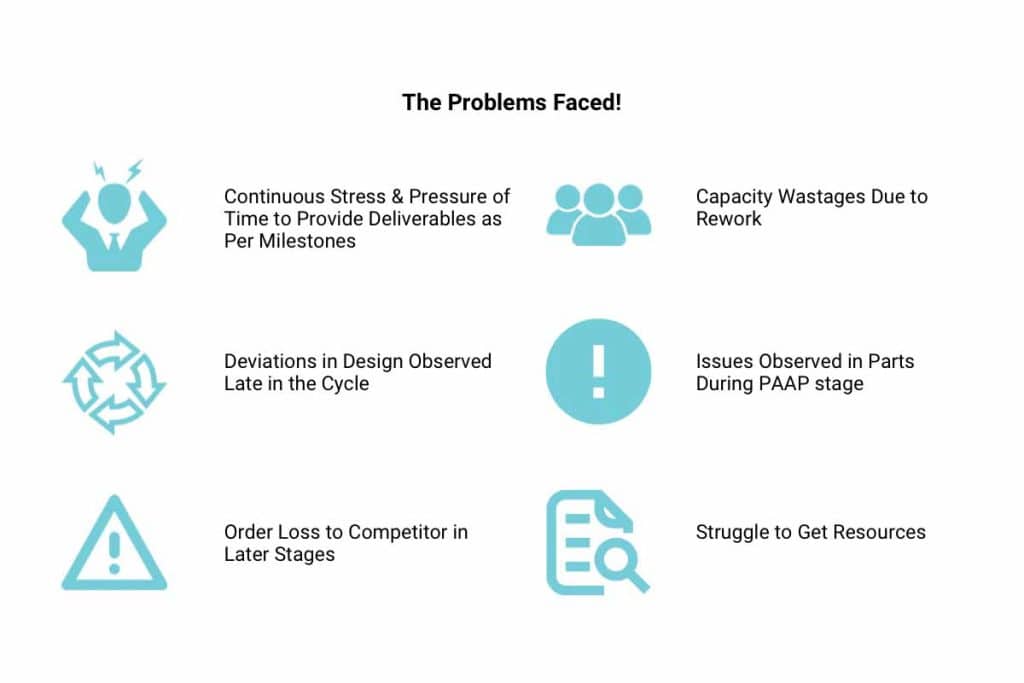

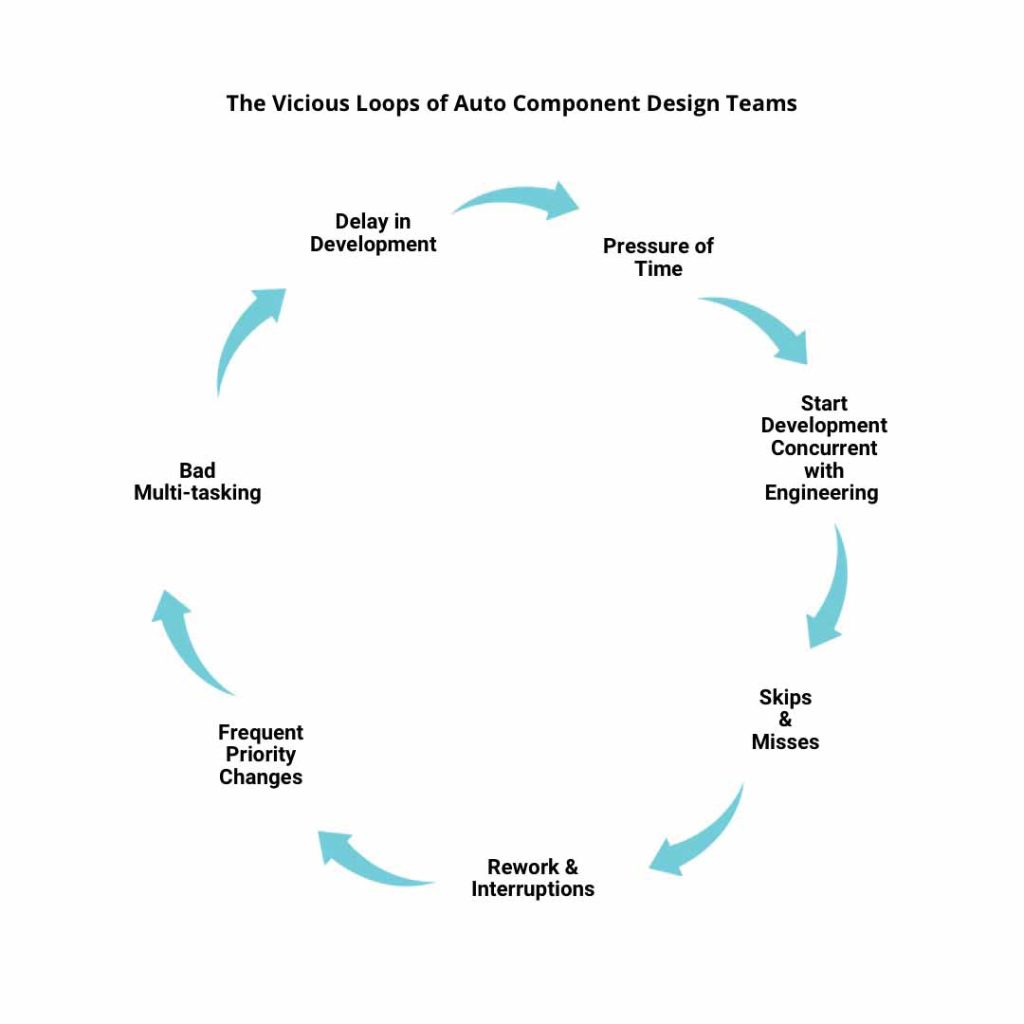

There is pressure from the top management to move the project to the tooling development phase. This often prompts OEMs to persuade vendors to concurrently start development with final tooling, even as the prototype is being finalised. The assumption is that this will help save time. This wishful thinking, however, never materialises. The components manufacturers proceed to hard tooling only to realise later that there are glaring gaps in design and or cost estimations. Any changes made to the hard tools are expensive and consume a lot of time. This leads to a series of actions in the advanced stages of development to minimise changes in design or even attempt to get some leeway from OEMs to accommodate whatever best can be achieved.

The juggernaut rolls

The situation is aggravated by the fact that any change made in an auto component can have a big impact on other interfacing components in a vehicle. One small late change in a component can therefore create urgencies for many auto-component vendors supplying for the same OEM. Invariably, the auto component manufacturers’ engineering teams find themselves juggling urgencies in the development work of different OEMs that they cater to. The Result – elapsed time in part development increases by leaps and bounds.

Also, each component may have multiple child parts coming from different (tier2) vendors – electrical, mechanical or electronics. The adhoc urgencies and escalations experienced by the component vendors trickle down to their tier2 vendors in turn supplying the child parts. This leads to de-synchronisation in the arrival of child parts and consequently leads to delayed testing. But since they have to meet the timeline expectations of OEMs, components are often mass-produced prior to completion of testing and full production stabilisation. Not only does this lead to a loss of production capacity, but many issues continue to remain unresolved since both the design and development teams are now forced to shift their attention to other new development projects.

This perpetual struggle of balancing the coordination issues and frequent delays makes the managers yearn for more detailed planning and scheduling. They also tend to believe that design mistakes are due to a lack of skill and or experience of designers. Frustratingly, however robust the plans are, and however skilled the designers are, neither of these helps the stakeholders in sticking to their plans or preventing re-work in design. This is because a large proportion of the planned timelines are under the ambit of OEMs. Variability in the timeline of a single task tends to have a cascading effect on all the subsequent tasks of the auto-component NPD team. Even a highly skilled designer will tend to have skips and misses in an environment of expediting citing urgencies. Under these circumstances, there must be a way out!

Conclusion

Adopt these four simple rules of having a design full kit before development, control WIP, performing high-frequency management, and monitoring projects ETC. In this manner, one can experience the lead time for NPD going down drastically (50 per cent improvement, at the least) while also leading to significantly better output (more than 100 per cent) in your organisation! ACI

———————————————————

Suhas Kini (XLRI) is a Project Manager with Vector Consulting Group. The company consults with auto, and auto component companies to solve chronic industry problems using a systems approach and by applying first principles thinking.

———————————————————

The opinions expressed within the content are solely the author’s and do

not necessarily reflect the opinions of ACI Magazine.

Also read, Localisation is the key to a resilient Indian automotive industry

Also read, Localisation is the key to a resilient Indian automotive industry