Battery Management Systems are increasingly finding a use case in liquid cooling. Ashish Bhatia looks at the grey areas of air-cooling, that suppliers have overcome.

Original Equipment Manufacturers are increasingly opting for liquid-cooled Battery Management Systems (BMS) in their Electric Vehicles (EVs). Drawing from the learnings gathered from liquid cooling in Internal Combustion Engine (ICE) vehicles, case-in-point, ICE vehicles using a gaseous liquid or a liquid coolant directed to the heat exchanger and further cooled by air. Prevalent in both cars and motorcycles, the liquid cooling component comprises the radiator fan and fan cowl, water pump and a thermostat as standard production equipment. The cooling system has found a use case in EV counterparts, including recently commercialised three-wheelers. With conventional cooling (air cooling) and the lack of standardisation found to make battery packs vulnerable to heat spikes, the case for liquid-cooling is stronger, perhaps more than ever before.

Original Equipment Manufacturers are increasingly opting for liquid-cooled Battery Management Systems (BMS) in their Electric Vehicles (EVs). Drawing from the learnings gathered from liquid cooling in Internal Combustion Engine (ICE) vehicles, case-in-point, ICE vehicles using a gaseous liquid or a liquid coolant directed to the heat exchanger and further cooled by air. Prevalent in both cars and motorcycles, the liquid cooling component comprises the radiator fan and fan cowl, water pump and a thermostat as standard production equipment. The cooling system has found a use case in EV counterparts, including recently commercialised three-wheelers. With conventional cooling (air cooling) and the lack of standardisation found to make battery packs vulnerable to heat spikes, the case for liquid-cooling is stronger, perhaps more than ever before.

Liquid cooling in ICE

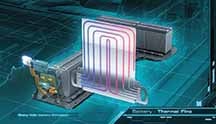

In the case of ICE, water is circulated to dissipate heat from overheating parts like the cylinder head and blocks. A cooling flan cools the water as it passes through the radiator. According to AIS-137 2015 notification, for vehicles of the categories M and N, liquid cooling circulation, in a testing environment, had to be operated by an engine water pump only. The liquid must be cooled either by the engine radiator or an external cooling circuit where the liquid comes in thermal contact with the engine component. It was bound to a condition that the pressure loss recorded in the circuit and the pump inlet pressure must match the engine cooling system.

In the case of ICE, water is circulated to dissipate heat from overheating parts like the cylinder head and blocks. A cooling flan cools the water as it passes through the radiator. According to AIS-137 2015 notification, for vehicles of the categories M and N, liquid cooling circulation, in a testing environment, had to be operated by an engine water pump only. The liquid must be cooled either by the engine radiator or an external cooling circuit where the liquid comes in thermal contact with the engine component. It was bound to a condition that the pressure loss recorded in the circuit and the pump inlet pressure must match the engine cooling system. The radiator shutter was required to be in an open state all this while. The auxiliaries included the fan, and the thermostat, and were chosen based on the desired net engine power. For the L category of vehicles, the standard production equipment also took into consideration, the engine bonnet and the bonnet air outlet. When measuring the maximum engine torque and the power, the temperature of the coolant at the outlet of the engine was required to be maintained within +/- 5K of the upper thermostatically controlled temperature, in line with the manufacturer’s specifications.

The radiator shutter was required to be in an open state all this while. The auxiliaries included the fan, and the thermostat, and were chosen based on the desired net engine power. For the L category of vehicles, the standard production equipment also took into consideration, the engine bonnet and the bonnet air outlet. When measuring the maximum engine torque and the power, the temperature of the coolant at the outlet of the engine was required to be maintained within +/- 5K of the upper thermostatically controlled temperature, in line with the manufacturer’s specifications.

Liquid cooling in EVs

Drawing from the learnings of liquid cooling in ICE, battery-pack and BMS, suppliers have been able to roll out EV solutions. Just like an overheating engine, the EV heat is traced to the battery pack. Charging and discharging are known to generate heat inside the cells and the interconnection systems. Known to be directly proportional to the square of the current flow, multiplied by the internal cell resistance, and the interconnect systems, it’s the current flow that dictates the heat proportion. This has a direct bearing on the battery performance. The electrochemical system, charge acceptance, battery power output, safety and TCO all are at stake here. To prevent the battery pack from malfunctioning in sub-zero temperatures, sub-30 degrees and above 40-degrees with the threat of a thermal runaway, the role of BMS is crucial to keep it in an operational range. According to the National Renewable Energy Laboratory (NREL), the temperature difference between cells must be limited to sub-three to sub-four degrees.

Drawing from the learnings of liquid cooling in ICE, battery-pack and BMS, suppliers have been able to roll out EV solutions. Just like an overheating engine, the EV heat is traced to the battery pack. Charging and discharging are known to generate heat inside the cells and the interconnection systems. Known to be directly proportional to the square of the current flow, multiplied by the internal cell resistance, and the interconnect systems, it’s the current flow that dictates the heat proportion. This has a direct bearing on the battery performance. The electrochemical system, charge acceptance, battery power output, safety and TCO all are at stake here. To prevent the battery pack from malfunctioning in sub-zero temperatures, sub-30 degrees and above 40-degrees with the threat of a thermal runaway, the role of BMS is crucial to keep it in an operational range. According to the National Renewable Energy Laboratory (NREL), the temperature difference between cells must be limited to sub-three to sub-four degrees.

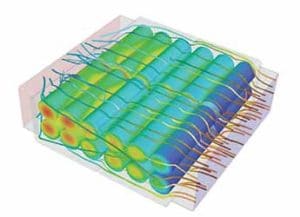

In liquid-cooling systems, piped cooling is one method. Found to be better at driving hot air away from the batteries in comparison to air-cooling, its flip side is the limited liquid coolant-carrying capacity. Liquid glycol has found acceptance by manufacturers like Tesla and GM. In this case, heat is transferred through a refrigeration cycle. The coolant has a more even distribution over the cells, as per studies conducted. To give a perspective, there are ~7,000 cells in a Tesla battery pack. In its Model S battery pack, the OEM is known to have used a metal tube arranged in a serpentine, patented pattern carrying the coolant that in turn comes in thermal contact with the surface of the cells. It is a series arrangement. In contrast, General Motors is known to have made use of aluminium, in a parallel arrangement. Porsche, in its Boxter E, is known to have used a liquid-filled cooling plate from the traction battery. In complete contrast to the above-mentioned approaches, some OEMs prefer to immerse the cells in a nonconducting fluid with a high boiling point.

In India, startup company Matter has made tall claims with its refrigerant system aimed at cooling overheated batteries. Mohal Lalbhai, Founder and Chief Executive Officer at Matter in a company release stated that “as the safety and performance of battery-powered electric vehicles are integral to their viability and acceptability, Matter has developed a highly purpose-built battery pack that will meet the needs of the electric two-wheeler industry.” Matter Energy 1.0, is claimed to be a breakthrough futuristic battery pack that uses a battery casing known to have been built using a lightweight metal that is thermally conductive compared to alternative materials. Claims Lalbhai, the company has prioritised the safety, battery life, and performance of the pack. Using an Integrated Intelligent Thermal Management System (IITMS) in the battery pack, the company makes use of an active liquid cooling system to ensure optimum performance of the battery elements. Designed along with the battery pack and BMS to suit the “heterogeneity”, the developments are claimed to be in-house. The super-smart BMS is a testimony to the focus on safety, security, reliability and performance of battery packs.

Tata Motors has announced a slew of electric passenger vehicle and commercial vehicle electric platforms leveraging a Common Architecture Shared Technology (CAST). In its ziptron technology and the Tata ACE EV, the company is known to have deployed liquid-cooled battery packs and has been able to back it up with extensive warranty. Explained Rajendra Petkar, Chief Technology Officer at Tata Motors Ltd., the company drew from the ‘Tata UniEVerse’ where it leveraged synergies with group companies like Tata Technology and external companies like Electra specialising in IoT for the electric powertrain. The Ace EV offers a 50 per cent higher range compared to electric three-wheelers. The lithium-ion phosphate battery pack from the company is liquid-cooled and very stable, reliable and thermally suited for Indian duty cycles. With the Euler HiLoad EV, Euler Motors launched the first three-wheeler with a liquid-cooled lithium-ion battery pack in the last fiscal. Similar to Tata Motors, Euler claims a 151 km certified range on a single charge. Handling a battery capacity of 12 kWh, coupled with an electric motor with an 11 kW peak rated power and a maximum output of 10.8 kW, the battery pack is again suited for both AC and DC charging and is claimed to maintain optimal temperature and assure a higher battery life. The use of a liquid-cooling system has aided in the company offering an extensive battery performance warranty as a testimony of the BMS system being efficient. By maintaining optimal temperatures, claimed Saurav Kumar, Founder and CEO, Euler Motors, the company was able to increase battery life by a margin of two years.

Tata Motors has announced a slew of electric passenger vehicle and commercial vehicle electric platforms leveraging a Common Architecture Shared Technology (CAST). In its ziptron technology and the Tata ACE EV, the company is known to have deployed liquid-cooled battery packs and has been able to back it up with extensive warranty. Explained Rajendra Petkar, Chief Technology Officer at Tata Motors Ltd., the company drew from the ‘Tata UniEVerse’ where it leveraged synergies with group companies like Tata Technology and external companies like Electra specialising in IoT for the electric powertrain. The Ace EV offers a 50 per cent higher range compared to electric three-wheelers. The lithium-ion phosphate battery pack from the company is liquid-cooled and very stable, reliable and thermally suited for Indian duty cycles. With the Euler HiLoad EV, Euler Motors launched the first three-wheeler with a liquid-cooled lithium-ion battery pack in the last fiscal. Similar to Tata Motors, Euler claims a 151 km certified range on a single charge. Handling a battery capacity of 12 kWh, coupled with an electric motor with an 11 kW peak rated power and a maximum output of 10.8 kW, the battery pack is again suited for both AC and DC charging and is claimed to maintain optimal temperature and assure a higher battery life. The use of a liquid-cooling system has aided in the company offering an extensive battery performance warranty as a testimony of the BMS system being efficient. By maintaining optimal temperatures, claimed Saurav Kumar, Founder and CEO, Euler Motors, the company was able to increase battery life by a margin of two years.

Simulation for real-world applications

“For electric vehicles to become mainstream it is pivotal that we focus on the product development cycle that is simulation intensive, thoroughly tested, and validated for reliability and safety. This approach is very important to be considered while designing and developing the battery pack,” opines Lalbhai. OEMs are seeking support from simulation software using computational models like Computational Flow Design (CFD) to ensure the real-world efficiency of such thermal management systems. According to a Comsol study, the use of time-dependent, and temperature analysis of the liquid cooling process, and thermal management can be improved and battery performances can be optimised.

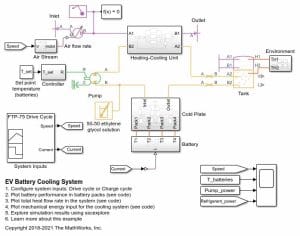

“For electric vehicles to become mainstream it is pivotal that we focus on the product development cycle that is simulation intensive, thoroughly tested, and validated for reliability and safety. This approach is very important to be considered while designing and developing the battery pack,” opines Lalbhai. OEMs are seeking support from simulation software using computational models like Computational Flow Design (CFD) to ensure the real-world efficiency of such thermal management systems. According to a Comsol study, the use of time-dependent, and temperature analysis of the liquid cooling process, and thermal management can be improved and battery performances can be optimised.  A MathWorks simulation software helps simulates an entire EV battery cooling system. The refrigerant system is used for cooling the overheated batteries. It represented the refrigeration cycle by the amount of heat flow extracted from the coolant. The system was simulated under either FTP-75 drive cycle or fast charge scenarios with different environment temperatures.

A MathWorks simulation software helps simulates an entire EV battery cooling system. The refrigerant system is used for cooling the overheated batteries. It represented the refrigeration cycle by the amount of heat flow extracted from the coolant. The system was simulated under either FTP-75 drive cycle or fast charge scenarios with different environment temperatures.