The recent developments in ICE have given it a new lease of life. Ashish Bhatia looks at permutations and combinations pointing at a longer-than-envisaged green run.

With all the emphasis on transitioning to net-zero emissions through EVs and Hydrogen fuel cells, Internal Combustion Engines (ICE) continue to evolve in the background and hold their own. It is far from being done and over with as the universal consensus. Most recently, the focus of Indian commercial vehicles OEMs on reviving ICE with combinations of natural gas and Hydrogen is a compelling reason for the suppliers and ancillaries to remain invested in innovation and real-world testing with ICE. There is an entire ecosystem dependent on it, and far from throwing the hat in the ring. The reorientation of the energy matrix and the realisation of being net-zero from well-to-wheel has sprung up new permutations and combinations. Here Hydrogen ICE seems to be the most exciting development followed by Natural Gas combinations closely following suit. The industry is striving for widespread acceptance in fleet operations to attain emission compliances in the near-term.

The push for it was more prominent in H1-2023 where multiple OEMs showcased CVs using their H2-ICE engines at Auto Ecpo 2023, in New Delhi. Tata Motors Ltd. displayed concepts including the Prima H.55S, the H2-ICE concept truck that gained widespread attention. Girish Wagh, Executive Director, in the past, has opined that the commitment and proactive actions leading to fructification of zero-emission technologies will enable customers to progressively and seamlessly transition to cleaner and commercially viable mobility solutions, as part of the short- and long-term goalposts. Wagh-led Tata Motors has advocated the preferential mix comprising conventional fuels, natural gas, and flex-fuel with H2-ICE (the company is banking on the 5.3-litre H2-ICE engine and the 2.2-litre CNG engine it showcased as an example) as a key inclusion over and above the Battery Electric Vehicles (BEVs) and Fuel Cell Electric Vehicles (FCEVs) being focused on for the long run. The better energy density means hydrogen has also emerged as a good alternative to prolong the life of ICE and extract more juice.

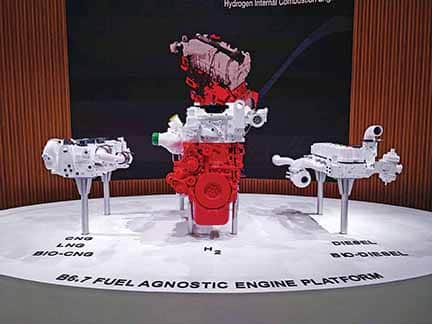

The renewed focus from Tata Motors also comes on the back of an MoU with Cummins Inc. signed in late 2022. A collaboration on the design and development of low and zero-emission propulsion technology solutions for commercial vehicles in India, it covered hydrogen-powered internal combustion engines. Back then, Tom Linebarger, Executive Chairman, Cummins Inc., had stated, “Cummins is well-positioned to help our customers successfully and seamlessly transition to economically viable decarbonised solutions. Cummins and Tata Motors have a strong history of partnership, and the next step into low and zero-emissions technologies is an exciting development for zero-emissions transportation.” Hailed as a significant step forward to achieving India’s Green Hydrogen Mission, the Cummins B6.7H hydrogen engine with up to 290 hp (216 kW) output and 1200 Nm peak torque was highlighted as an all-new engine platform featuring cutting-edge technology to enhance power density, reduce friction losses and improve thermal efficiency. It came with an assurance of compatibility with the same transmissions, drivelines, and cooling packages. Derived from the fuel-agnostic platform, Cummins is claimed to offer the benefit of a common-base architecture and low-to-zero carbon fuel capability.

In August 2023, Tata Cummins Pvt. Ltd. entered into an MoU with the government of Jharkhand to set up a manufacturing plant to produce low-to-zero-emission technologies for mobility solutions. This entails an investment of Rs.350 crore to produce fuel-agnostic powertrain solutions including H2-ICE besides fuel delivery systems. The plant is expected to commence production in 2024 in a phased manner. As per current plans, the Hydrogen Internal Combustion Engine will roll out first. It is the means to attain near-term zero-carbon emissions for medium- and heavy-duty truck and bus manufacturers.

Around the same time, Ashok Leyland Ltd. showcased the H2-ICE solution apart from Liquefied Natural Gas (LNG) and Compressed Natural Gas (CNG) covering both the truck and bus segments. With the AVTR platform at the core of this strategy, as per Sanjeev Kumar, Business Head – M&HCV, the company can retain the basic geometric and structural integrity of vehicles built using the modular approach. As per Dr N Sravanan, President and Chief Technology Officer, the OEM has an in-house capability on H2-ICE apart from diesel, CNG and LNG. In the case of H2-CE, it is leveraging its partnership with RIL for the tweaks to make the engine run on Hydrogen. It has also added LNG and CNG hybrids to the mix. In the case of NG, the architecture ensures that the gas is supercooled and cryogenically stored in liquid form in a tank mounted on the truck. There is a high degree of sub-aggregates commonality to offer high-performance reliability.

VE Commercial Vehicles Ltd. is also well poised to harness this opportunity. It displayed its H2-ICE engine to create a level playing field. On the Pro 8055 series, the company came up with an LNG and CNG (bi-fuel) hybrid. While LNG aids operators in meeting long-haul needs, CNG comes to the fore for denser distribution networks. As per Vinod Aggarwal, Managing Director and CEO, the company is confident of playing its part with a mix of solutions including LNG, Ethanol and Hydrogen deemed essential to lead decarbonisation. From the Volvo Trucks stable, the FM LNG 4×2 Tractor Head, as per Boddapati Dinakar, Executive VP – Volvo Trucks India – VECV, the unique diesel cycle technology provides a 15-20 per cent improvement in fuel economy to make a case for long-haul alternative fuel transport. The 13-litre platform will be offered as a diesel duty cycle and not a petrol or an Otto cycle (constant volume cycle). The result is a 20-25 per cent lower carbon footprint. On ICE, the company has added advanced features to convince the customer of a value proposition including a more efficient engine management system, gearbox, and after-treatment system among other critical inclusions. The company based on its learnings from the EU pilot, is in a position to make it available for different axle and horsepower configurations. H2-ICE is being hailed as a step in the right direction for speeding up the evolution of a hydrogen-based economy to meet emission targets in the near term.