Battery safety has turned a big question mark. Ashish Bhatia with Prateek Pardeshi checks on the push for building cost-effective and safe battery packs.

The reliability of Battery Electric Vehicles (BEVs) has taken a beating in the recent past with ad hoc fire incidents being reported across the countries. This has especially hit the prospects of two-wheeler EV startups that gained an initial traction by riding on the clean and green mobility wave. With the government intervening and compelling manufacturers to recall suspect product batches, including standardising EV battery packs, the focus has gone beyond building cost-effective battery packs to building safe and stable battery packs. As per Pratik Kamdar, Co-Founder, Neuron Energy, “A lot of players are entering the industry without comprehensive knowledge of the batteries with regards to quality. The industry is still a fledgling one and the majority of dealers and customers are not educated or aware of the technology.” He advocated the need for a regulatory framework so that the EV manufacturers and battery makers are held accountable for use of cells, Battery Management Systems (BMS), and compliance with regulations. “Even low-speed bikes need to be regulated by the government. EV manufacturers and battery makers should use fire-resistant grade battery materials along with superior BMS and best quality cells so this kind of fire accidents can be avoided in the future,” he asserted.

Forcing a rethink

There has been a spurt in vehicles catching fire across the board. Two-wheelers here are under greater scrutiny with some of the promising high-performance EVs failing to impress. Allegedly due to issues like “short circuit’ there have been instances where the battery packs have led to the vehicle catching fire causing fatalities of both the rider and the onlookers. For instance, in Andhra Pradesh, it was alleged that the portable battery pack on charge within the owner’s house premises exploded in the wee hours of the morning. It is said to have killed one and injured three. In another incident, in Nizamabad, Telangana, the battery pack explosion is known to have killed an eight-year-old.

Naturally, the EV industry has faced a lot of heat and literally so! Kamdar blamed the substandard quality cells that are used by a majority of battery companies to manufacture battery packs with poorly installed BMS. This causes high energy density cells to lead to thermal runaway and increase the risk of fire. A thermal runaway is said to occur when a lithium-ion battery overheats triggered by acts of overcharge, a short circuit or other cell-related stress in the absence of an adequate cooling system. A chain reaction in the cell that generates gas is triggered by excess heat. To overcome these, testing and certifying battery swapping components are of utmost importance. In line, the recent EV draft policy states that the standards approved or defined by BIS shall be implemented for the electric vehicle, battery safety requirements, degrees of protection (IP-code) of electrical equipment against foreign objects, technical specification of cables and connectors, and traction battery safety requirements.

Kamdar also urged EV manufacturers to provide better spacing for batteries and to avoid the obsession with extreme compact sizes of batteries. “This can also be a cause of thermal runaway eventually leading to fire incidents. These instances can be avoided by reducing the under-seat storage by 30 per cent. Vibration pads need to be used to further ensure the stability of the battery pack. Thermal pads are required to be installed to ensure there is sufficient cooling mechanism,” he asserted. Besides measures on the supply-side, Kamdar also urged ensuring checks in places while transporting an EV from the manufacturer to the dealer. “The standard operating procedure should be followed while transporting an EV from the manufacturer to the dealer. Batteries should not be connected to vehicles during transportation. Batteries should be kept at a 30 per cent state of charge to avoid any risk of fire during transportation,” he added. Besides the above mentioned good practices, it is also imperative to store batteries in a cool and dry environment and avoid direct sunlight and water. Owners must take special care to quarterly service these batteries as fire instances do not occur in a day. “It takes 10-15 days before catching fire. If the batteries are being checked or serviced regularly such incidents can be avoided, stressed Kamdar.

Compliance checks in place

It is learnt that the battery packs shall be tested and certified as per AIS 156 (2020) and AIS 038 Rev 2 (2020) standards for the safety of traction battery packs, as well as additional tests that may be prescribed for swappable batteries which are subject to multiple coupling/decoupling processes at the connectors. To ensure a high level of protection at the electrical interface, a robust infrastructure will be built that includes a rigorous testing protocol being adopted to avoid any dielectric breakdown, arc phenomenon, or any unwanted temperature rise at the electrical interface. BMS of the battery must be self-certified and open for testing to check its compatibility with various systems. This capability must meet safety requirements. Here, the compatible electric vehicles shall be tested as per relevant regulatory standards. For EVs with swappable battery functionality, vehicle OEMs shall be required to get ARAI approval for their vehicles to accept interoperable swappable batteries.

Localisation of battery packs

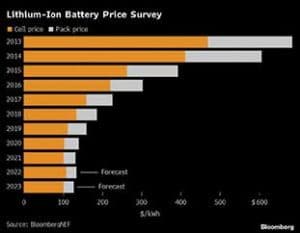

EVs are known to have a high acquisition cost. On the supply-side, OEMs have justified this high initial acquisition cost with a low Total Cost of Ownership (TCO) over the vehicle life cycle. The per kilometre charge consumption is said to outdo the running cost of Internal Combustion Engine (ICE) counterparts. The battery pack in an EV is the highest contributor to the customer acquisition cost. However, it is also true that globally, battery pack costs are coming down. Cited Vishnu Rajeev mentioned, “Lithium ion battery value has come down drastically due to the course of massive investment which has gone into developing new technologies. Also with lithium-ion having few shortcomings we are currently developing alternatives such as sodium-ion and other technologies.” In the short term though costs of battery cells have seen a 20 per cent spike blamed on the global surge in raw material prices that includes lithium. The prices are expected to remain higher for another year, it is believed. The Russia Ukraine war crisis has had a bearing here. The industry is also looking at means like recycling to enhance the raw material availability and offset price hikes.

In India, several supporting initiatives are promoting affordable EVs by way of localising battery packs for OEMs to realise economies of scale. From the Faster Adoption and Manufacturing of Hybrid & Electric Vehicles in India (FAME), I and II outlay, to the Production Linked Incentive (PLI) scheme for the National Programme on Advanced Chemistry Cell (ACC) Battery Storage (NPACC) to boost indigenous battery manufacturing capacity. State governments are also developing complementary policies to promote EV adoption according to Vishnu Rajeev – Head of Micelio Fund. He cited, “Battery of EV accounts for almost 40 per cent of the total cost of the EV.” He also drew attention to the traditional purchase pattern of EVs wherein “fixed” batteries are capable of only being charged using the external charging station while housed within the EV undergoing a transition with the advent of portable charging and swapping alternatives available to the customer.

Building economies of scale

There are no two ways of bringing the battery costs down. Localisation apart from the use of alternative and rear earth free metals is the most effective one that the industry has resorted to. India does not possess critical raw materials such as lithium, cobalt and nickel, which are used to make lithium-ion (Li-ion) battery cells. For example, Lithium-ion reserves are majorly found in two countries: China and Chile and recent trade volatilities have created a supply bottleneck, de stabilising the supply and demand equation. Indian manufacturers continue to rely heavily on imports of battery cells from China, Japan, Korea, and Taiwan for assembly here. Most Indian bidders after the PLI scheme, are expected to commence localised manufacturing only by 2025. So, India’s import-driven strategy, for the domestic assembly of critical battery packs, will continue for a few more years giving a ray of hope for a turnaround sooner than later.

Among promising initiatives, Reliance New Energy Ltd. acquired assets of Lithium Werks. The net transaction value of USD 61 million includes funding for the future growth strategy. Commenting on the Lithium Iron Phosphate (LFP), Mukesh Ambani, Chairman of Reliance Industries Ltd. is known to have said “LFP is fast gaining as one of the leading cell chemistries due to its cobalt and nickel free batteries, low cost and longer life compared to Nickel Manganese Cobalt (NMC) and other chemistries. Lithium Werks happens to be one of the leading LFP cell manufacturing companies globally and has a vast patent portfolio and a management team said to introduce an immense value-add, especially in innovation across the LFP value chain. In another example, Log9 Materials inaugurated a cell manufacturing plant in Bengaluru. It is expected to attain a 50MWh capacity in a span of one year. It is positioned as one of the largest cell producing units in the whole of SouthEast Asia. The RapidX battery packs powered by InstaCharge technology are claimed to offer a 9X enhanced charging capability and better life. Omega Seiki Mobility (OSM) is known to have committed USD 250 bn for an electric three-wheeler manufacturing plant that also entails a battery pack supply chain. Suzuki Motor has committed to an investment of Yen 150 bn for EV projects including a battery plant in Gujarat. Tata Motors could benefit from subsidiary Tata Chemical’s interest in a battery manufacturing unit in Gujarat too.

Stressing the need to simulate fuel stations for ICE vehicles, deemed adequate, affordable, accessible, and reliable, he added that charging networks are required to attain a similar scale as a prerequisite for mass EV adoption. Efforts are underway in India to boost the availability of charging infrastructure with the recent tie-ups at public and private infrastructure and the emergence of special mobility zones in the country. Charging still takes a significantly longer time than refuelling an ICE but the customer has come to terms with overnight charging. Technology on the other hand has caught up to several claims of fast charge among capabilities like brake energy regeneration. Battery swapping is an alternative which involves exchanging discharged batteries for charged ones and provides flexibility to charge them separately. This de-links charging and battery usage and keeps the vehicle in operational mode with negligible downtime. Battery swapping is generally used for smaller vehicles such as 2Ws and 3Ws and even buses using systems from companies like Sun Mobility. The smaller batteries are easier to swap, compared to four-wheelers. Battery swapping falls under the broader umbrella of Battery as a Service (BaaS) which involves users purchasing an EV without the battery. This is found to have been an effective, safe alternative aimed at significantly lowering up front costs, by paying a regular subscription fee on a daily, weekly, and or monthly basis as deemed fit by the customer. BaaS is applicable for both fixed and removable batteries and is the channel for implementing the swapping solutions. ACI

Stressing the need to simulate fuel stations for ICE vehicles, deemed adequate, affordable, accessible, and reliable, he added that charging networks are required to attain a similar scale as a prerequisite for mass EV adoption. Efforts are underway in India to boost the availability of charging infrastructure with the recent tie-ups at public and private infrastructure and the emergence of special mobility zones in the country. Charging still takes a significantly longer time than refuelling an ICE but the customer has come to terms with overnight charging. Technology on the other hand has caught up to several claims of fast charge among capabilities like brake energy regeneration. Battery swapping is an alternative which involves exchanging discharged batteries for charged ones and provides flexibility to charge them separately. This de-links charging and battery usage and keeps the vehicle in operational mode with negligible downtime. Battery swapping is generally used for smaller vehicles such as 2Ws and 3Ws and even buses using systems from companies like Sun Mobility. The smaller batteries are easier to swap, compared to four-wheelers. Battery swapping falls under the broader umbrella of Battery as a Service (BaaS) which involves users purchasing an EV without the battery. This is found to have been an effective, safe alternative aimed at significantly lowering up front costs, by paying a regular subscription fee on a daily, weekly, and or monthly basis as deemed fit by the customer. BaaS is applicable for both fixed and removable batteries and is the channel for implementing the swapping solutions. ACI