Story by: Sricharan R

What happens if a machine communicates to the concerned people about its requirement? This is exactly what the machine tool manufacturer Bharat Fritz Werner is looking at. Popularly known as BFW, the company in its R&D centre is working on a machine that communicates directly to the respective department and gets its work done quickly.

“What we are talking about is the next generation of manufacturing, the smart factory. It can no longer be dependent on people having knowledge. If a machine becomes dependent on the people, it can only work if skilled people are with it. Going forward, the factories themselves should take decisions. The equipment in the factory should take decisions, and the shop-floor and top-floor should be seamlessly linked. At the same time, neither the machine nor the shop-floor should be isolated. So, we will have a factory communicating to another factory, machine talking to another machine and so on. That is how it should be. With this in mind, we have a machine in R&D. This machine can communicate. For example, if a motor gets heated up, it informs the concerned person. The message will reach the concerned department and gets rectified,” Ravi Raghavan, CEO and MD, BFW, said.

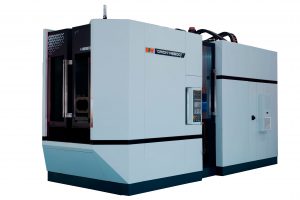

Headquartered in Bengaluru, BFW designs and manufactures precision machine tools, mostly computer numerically controlled (CNC) vertical machining centres and horizontal machining centres, horizontal turning centres, vertical turning centres and special purpose machines. Founded in 1961, the company is a flagship of the Kothari Group. It was started in collaboration with Fritz Werner Werkzeugmaschinen GmbH of West Germany. Most of its manufacturing and assembly processes occur at the company’s main facility in Bengaluru. BFW is scaling up its research and development centre to cater to the increasing needs. The company spends up to 0.6% of its revenue in R&D. Last year, the company expanded to Hosur and doubled its capacity. This facility will be like a smart factory and BFW is building it with all the new technologies it has. It is scheduled to be completed this year.

About the new machine that communicates, Ravi said, “The prototype of the machine is being made in the factory and it will be out in a couple of months. An example of how it communicates is: if the machine is needed to be shifted from the factory to a customer in Delhi, it sends out messages to the customer on the coordinates through the GPS, seamlessly. The owners of the heavy machines are small shop owners and he cannot rent a crane for a whole day. As the machine communicates he can do the needful whenever required. We have programmed and have given it certain fences. Another example is that when the machine’s oil level comes down, the sensor in it detects and sends a text automatically to the supplier and he supplies it. On the whole, the machine takes care of itself.”

The company recently entered into a partnership with Universal Robots to penetrate other sectors with affordable and new automation solutions. Ravi said cobot is a new trend and BFW is working on it also. There will be data analysis, sensor technology, IoT and many other parts of technology that helps the company to move forward and improve productivity. “Things like cobots are intelligent, smart, and they add much more value. Above all these, they are easy to use. What we are trying to do is to add value in everything,” he said.

BFW does whatever it takes to enable progress by acquiring new technology to serve its customers better. It is working on multiple processing machines and is building machines to bring out lightweight products. “On multiple processing machines two things are happening. Earlier, the lot sizes were big and we could take one model, make a huge number and change it. Now, people are going for smaller batches and for this, the machines need to be flexible. Secondly, when the batch size is small, there will be one component in 10 machines. Shifting from those 10 machines would not yield better results. So, people want to finish everything in a single machine. This is where we are spending a lot. We have put a five axle machine and similar to that we have a couple of other multi-purpose machines. We have tied up with a company in Spain to manufacture these. In the same way, we are also developing a multi-purpose machine which could even hold a robot built inside the machine. These are very complex and it will be our answer for complex low-volume factories,” Ravi said.

Light-weighting

On the light-weighting components, he said people are not thinking much about light-weighting, but this is where BFW focuses on. In his view, light-weighting can only happen with the use of different alloys having different properties. With this in mind, the company is building machines that will be suitable for many light-weighting alloy components. This may not give great benefits in low-end steel but, taking those materials will show an enormous effect in the finish, productivity etc.

“The vibration of these will be 1/10th of what we witness in normal machines. The new machine is being built with all the benefits in it and this is going to be the next big thing because with the entry of EVs, light-weighting will play a major role in power consumption and battery life,” he said.

Disruptive technologies

About disruptive technologies like 3D printing and EVs, Ravi said, “EVs will affect the market, but only a little bit as the number of components will be reduced. But, according to the studies that the various industries have done, by 2030 even when 30% of the auto industry is getting converted to EV, the machine tool industry will continue to grow. The impact will be of 1-3%, depending on the type of machine. Nobody has done a study on after 2030 and we have no idea about that. EVs will have an impact. But many other needs are also coming up. That is why some of the simpler machines will face the challenge and people will have to go for a new and different application.”

On additive technology, the CEO said, it will not remove the subtractive manufacturing as it is not an alternative to it. “We believe 70% of manufacturing will require subtractive, and additive cannot replace it. Of the remaining 30%, about 10% additive can be directly used. In the remaining 20%, there needs to be a lot of engineering done, even in the design of the component. This will make the additive effective. For example, if I take a component that we are making subtractive and make it in additive, it is not going be an advantage. I am not going to be benefitted from it. But, if I engineer it, design the component in a way suitable for additive, then the benefit will be there. So, the additive will have an impact, but only on certain components. Cost also plays a major role here,” he added.

Ravi said they have plans to be part of the additive technology. But, they are waiting to learn new things as it is an evolving industry. BFW is looking at all possibilities and is learning on what is the best way to go forward. As they are in the metal industry, they will not get to polymer and glasses. Sharing his views on the growth potential of the Indian market, he said, they are looking at growth in small jobs that does a lot of small-batch components. Other areas of small jobs include power, infrastructure etc. Construction equipment and dying moulds are also the areas where they witness growth.

Speaking about the market from India’s perspective Ravi said, “By 2024, the government plans the manufacturing GDP should be 1 trillion dollars. Today, it is less than 300 billion dollars. We are talking about 3 times growth in 6 years and manufacturing cannot grow if machines are not here. The machine tool industry has a huge opportunity to grow. The second part is, China used about 30 billion dollars worth of machine tools and we use about 2 billion dollars. So, the growth will happen in the next 6 years. Then it will slightly slow down because of EVs and other things coming in.