Mahindra Intertrade has signed a Memorandum of Understanding (MoU) with MSTC Ltd. (a Government of India enterprise formerly known as Metal Scrap Trading Corporation Limited). The MoU will see the companies undertake a joint initiative to set up India’s first auto shredding facility. Auto-shredding in India is largely an unorganised activity with vehicles long past their usable life still in use, especially in rural and semi-urban India. Older vehicles are currently dismantled in an unscientific manner, hazardous to the environment. The extent to which the vehicle is recycled is also very minimal, with most vehicular residue making its way into landfills. The proposed facility will be equipped with state-of-the-art, fully automated end-of-life vehicle recycling equipment and will be India’s first such facility. This will go a long way in the efficient recycling of scrapped automobiles.

Speaking on the occasion, S K Tripathi, Chairman & Managing Director, MSTC said, “We are delighted to partner with Mahindra Intertrade for this industry first initiative. MSTC is always looking at innovative ways to recycle scrap and protect the environment and this facility will help to participate in the emission targets which India has promised to fulfill via the COP 21 Emission Treaty.”

“The concept of vehicle scrappage is still new to India as compared to the West where it is a lucrative industry. While the number of cars has increased substantially over the last two decades, there is no recycling or scrapping provision in place to deal with old and discarded vehicles. Recycling, if done correctly, is not only environment friendly but will also help keep older vehicles off the streets. We are delighted to have MSTC partner with us in this project which presents so much potential,” said Zhooben Bhiwandiwala, Managing Partner, Mahindra Partners.

According to Sumit Issar, Managing Director, Mahindra Intertrade, “Our study indicated that recycling not only saves energy costs but also minimises the need for other resources as every tonne of new steel manufactured from scrap steel saves a substantial amount of iron ore, coal and limestone. Moreover, if India focuses on scrapping old automobiles, it can recover significant amounts of steel scrap, aluminium scrap, plastic and rubber. Hence, there is a pressing need for facilities such as this one.”

Given the new stricter norms related to road worthiness of automobiles, a huge number of vehicles are expected to come under the end-of-life category in India. This initiative will not only revolutionise the way automotive scrap is generated and procured in India, but will also help reduce dependence on imports, providing steel mills with a one-stop solution for all their metal scrap related needs.

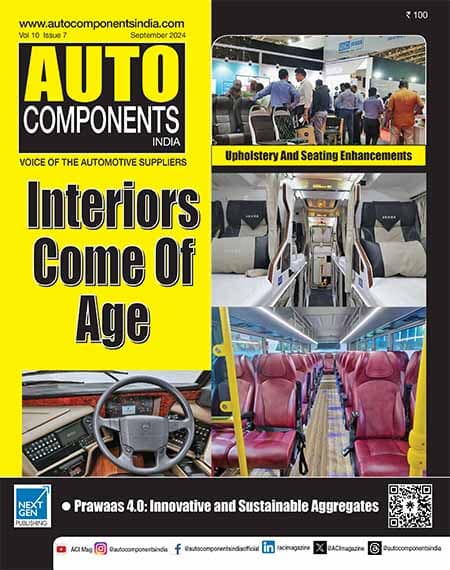

*Photo used for representational purpose only.