Cost optimisation against value for money is intrigued by RLE International. The global engineering company is looking at offering end-to-end engineering solutions by leveraging “Global Capabilities” at a “Local Cost” in India.

Text: Bhargav TS

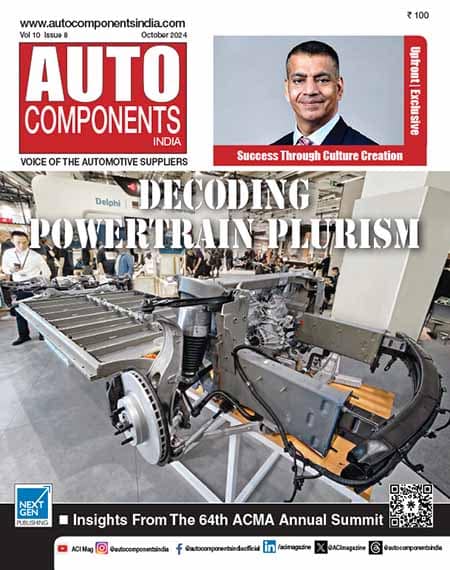

RLE International a German-based engineering company has proven its excellence in engineering over 3 decades and showcases its design thinking expertise in the field of automotive and other industries. RLE India, a 100% subsidiary of RLE International is offering end-to-end services far the past 10 years in Body in White (BIW), interior, exterior, system integration, powertrain and chassis, Computer Aided Engineering (CAE) and data migration and is now looking at expanding its business in India by entering into new avenues. The company currently has offices in Bangalore and Chennai and is investing heavily on setting up Centers of Excellence (CoE) in core areas of automotive engineering.

The Managing Director and COO of RLE International, Robert P Rupa told Auto Components India that, “the vertical integration of commodities have lot of challenges to deal with and we are in the phase of encountering it. There are certain complexities on one side but on the other side we stick on to our deliverables inputting necessary contingency attributes like lightweighting in the components. The platform we develop for India not only serves India but globally. Cost consciousness in all the areas of technical inputs does not make sense and it is not feasible to the desired extent. We would still work on leveraging the cost but only in certain niche areas. The product we deliver proves the value for money and the best in class engineering excellence will be catered to all our engineered products and OEMs will use the engineering inputs globally irrespective of the market,” he added.

RLE India has strengthened its business relations with key Indian OEMs and suppliers and is now looking to scale up their business in the country with an expectation of 30% YoY growth. Darren Gowland, Group Vice President International Operations, RLE International said, “We aim for RLE India to become a leading player in 2-3 niche segments in India and to become one of the top 3 players in transportation segment adding more OEMs and Tier 1 customers. Going by the global standards, we have already added new service lines like automotive electronics, BIW and design using lightweight material to support the new needs of our customers and our goal is to grow further in India.”

The company is working on infotainment and all driver assistance systems and in 2-3 years the output of which will be realised and OEMs will start investing in the technologies which proves its superiority, feels Gowland. The company lauded that the support from the government with regards to infrastructure should be commendable for an effective initiation of electronic feed to Indian vehicles. Though the company’s core area is not electronics, they do have a 10% segment in engineering the electronics like powertrain ornamentation.

The company now focuses much on Euro V standards and has a check from OEMs to have the crash performance output satisfactory. According to RLE, there is a sinister alarm for IC engines and the road for IC engines are blurred. Robert commented that, “As markets are now very keen for hybrid and electric vehicles, the strategy has to be redefined from our end and should have a different approach and design parameters. In India though everybody speaks about hybrid and electric vehicles, there is a need for infrastructure in roads. The quality of infrastructure also has to meet certain guidelines. India is a very big market along-side China and OEMs are showing much inclination towards investing in the markets. The technology usage is already getting exhausted in Europe and US as the market easily embraces the latest technologies in their vehicles. Electronic energy is weak in Indian vehicles and the market portends a huge hit for the OEMs.”

Body engineering is the major work the company does for OEMs which involves engineering the body structure like interiors, exterior doors, ergonomic engineering, chassis work and little bit of power train integration. Employing aluminium and fiber composites in the body structure, plastics in the interior have become pretty standards of-late. From concept to design the company works with all OEMs, prototype their components and with minimum iterations and they pass through the testing phase. Hiring and bringing expertise across geographies is the company’s motto as the simulation plays a vital role in all its engineering outputs.

“The technological inputs as of now in India definitely gets varied when compared to Europe, US and other countries. The trend, regulation everything has to be monitored when the vehicles are fed with technical inputs. We contemplate much and develop vehicle design for future India,” said Robert.

RLE International is planning to make significant investments on skill development and to set up several Centers of Excellence (CoE) in the next 5 years in India which would support the RLE Group’s overall business across geographies. RLE India is creating 2 focused growth engines in India – Product Engineering and Manufacturing Engineering and is also planning to invest 10% of its revenues annually towards expansion of its business portfolio. The company’s focus in India currently lies in building innovative solutions in lean engineering, manufacturing engineering, automotive electronics, lightweight materials and vehicle safety.

Speaking about the R&D centre, Gowland averred that, “Though OEMs have their R&D centre built-in not all the intricates will be taken care at their centre. Some re-engineering of the components have to be outsourced to companies like us. With our design inputs and prototype success the OEMs will start working on manufacturing and product development. We work on aluminium and fiber composites for bringing in weight reduction to the vehicles and restructuring the vehicles with those components.”

Make in India though has become viral throughout, the company’s contribution to this may not be in the form of tangible measure but there are skill and knowledge impartation from its end which is the fundamental concept of Make in India. Lot of OEMs plan to work and manufacture things in India for 2 reasons, like work force hiring at a minimum cost and qualified people with niche talents. Robert commented that RLE works with suppliers and OEMs and they look for right talents and no doubt India is a globe of talent and efficient workforce.

He further commented that, “We work with US and Europe customers and unambiguously the talent pool in India supersedes the other countries. When we initially launched in India, the aim was merely to be an offshore delivery centre catering to some of our global customers. But over the years this market has proven itself to be much more promising and it is one of the high-performing markets today catering to creme customers with quality services. For our global customers we develop and manage commodities and total vehicle projects from design to production and are heading to become one of the market leaders in India within the next 5 to 8 years. The market is challenging but we have the right expertise, the right experience and the right investment strategy to grow further,” added Robert.

As compared to other players in the market, RLE India brings in “Global Expertise” and also carries the benefit of global capabilities to “Follow the Customer” and support them in multiple geographies. Unlike the otherwise popular “Resource Augmentation” model, RLE India has developed the “Managed Staffing Solution” to support customer’s in-house engineering requirements. The Managed Staffing Solution ensures lowest Total-Cost-of-Ownership (TCO) to the clients.

Commenting on the reduced product life cycle, Gowland replied that, the psychology of the people brings in more business for us. Obsolescence has become pervasive and the life of the vehicles have become very short. New models are expected in short durations which lime lights the importance of re-engineering. The platform re-engineering requires at least 18-24 months. The feasibility of introducing new platforms in a shorter duration is a million dollar question. The OEMs will not introduce new platforms to ensure their quantity as quality of the platform and the contentment of customers while adapting the same matters them a lot.

The newly appointed Managing Director of RLE India Vijay Machigad said, “India is a booming market for automotive engineering industry and RLE India has already come a long way since its inception. During the next few years, we aim to grow multiple folds not only in terms of revenue but also in terms of our service portfolio, business footprint and customer relations.”

The company has planned to invest 100 million Euro for skill development and futuristic capabilities and it would be on a long term basis. “There seems to be a lack of availability of high-end skillset. RLE plans to invest on skill development as well as leverage its global expertise to offer niche solutions in India. While RLE India’s key focus is on quality, the highly cost competitive Indian market poses a huge challenge, as cutting on price means compromising on quality and safety. Our “Follow the Customer” and “Global Capability at Local Cost” strategies would help us build strong relationships with our customers and deliver high value,” added Machigad. ACI