Story by: Sricharan R

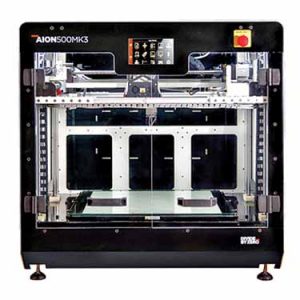

The roots of 3D printing or additive manufacturing can be traced back to 1986. It was when the first patent for Stereo Lithography Apparatus (SLA) was issued to Charles Hull. Back then itself the technology was considered to have the potential to democratise the production of goods. Three decades later, the belief has only grown stronger. With a wider degree of the acceptance of 3D printing especially in the machining sector, Divide By Zero Technologies, a leading provider of 3D printing technology to the Small and Medium Enterprises (SMEs) has found it to be the opportune time to launch the AION500 MK3, which is being touted as the world’s fastest Fused Filament Fabrication (FFF) 3D printer. “This is approximately 10 times faster than any other 3D printer in the technology. When it comes to small-batch manufacturing, this can compete with CNC and high-speed machines,” claimed Swapnil Sansare, Founder, Divide By Zero, in an exclusive conversation with Auto Components India. “One can print 10 different components each with different contour and geometry at the same time which makes this better than other machines. When an OEM requires a small batch of different components, CNC would bring out a huge cost. That is where the new AION500 MK3 (MK3) made in India printer comes into the picture,“ opined Sansare.

The new MK3 is powered with DBZ-patented technology called Advanced Fusion Plastic Modeling (AFPM). It is claimed to print at 10 times faster speed compared to existing 3D printers, and without compromising on the mechanical properties, surface finish and accuracy. The MK3 makes use of a special blend of polymers which can be printed faster than conventional 3D printers and is said to be IoT-enabled. The multiple connectivity options and sensors are said to make it one of the most advanced 3D printers available across the globe. “This machine has a speed of 1.5 m per second. We wanted to compete with the CNC machines. In comparison, this needs 2-3 hours time for printing, while a typical printer would take 10-15 hours,” claimed Sansare. The MK3, additionally allows people to work on variable temperature and flow based on the path geometry. It reads the tool path length and decides on the temperature and flow. Sansare claimed that besides a faster speed, the company scores on the component strength front too, making MK3 stronger than its competitors.

Serving clients like Daimler AG, Mercedes-Benz, Motherson Sumi, and Ford Motor Company, the company has come to establish itself as a serious player in 3D printing with clients spread across the country in Mumbai, Delhi, Bengaluru, Chennai, Pune, Ahmadabad, Rajkot, Coimbatore, and internationally in Malaysia and Dubai. Divide by Zero’s range of high quality, industrial 3D printers like the MK3 are known to cater to various business, and in turn, presenting opportunities to engineers and designers in the automotive sector. Beyond the auto industry, the solutions also extend to architects, educators, medical researchers and innovators. Looking to be a service-oriented company, the company is looking to offer a value proposition through each of its solutions. The company is looking at business opportunities across industries including automotive, medical, medical-surgical models, jig fixtures, casting patterns etc.

With a vision to be a globally admired leader in the advanced manufacturing industry, the company is offering innovative, simple and high-performance products. It is actively scouting for opportunities to supply to the MSMEs. The company works closely with professionals and customers from various fields to improvise on existing technology and providing the additional benefits of advanced 3D printing technology to our existing and potential clients. Said Sansare, “We have a channel network and conduct webinars every month. This is done mainly to make people understand how they can run it in their areas. We are reaching many through government clusters in Bengaluru and Chennai. This is how we create awareness and educate them,” he said.

Apart from the MK3, the company is working on various new products including a metal laser sintering printer. It is also working on polycarbonate and other new materials which can add more strength to the components. According to Sansare, solutions like the MK3 have opened up new segments like aerospace, precision casting for the company. Explaining that the subtractive and additive can go hand in hand, a process that it is called ‘hybrid manufacturing’, it is a solution that the company is looking to offer in the future.

Speaking on the concern of 3D printers expected to cannibalise the market of CNC machines, expressed Sansare, “The CNC will not go away completely. Customised manufacturing will have a huge role to play and 3D printing will complement the CNC. The machines of tomorrow might have both additive and subtractive both in one single machine, using the best of both.” With the cost said to be a major deterrent for the acceptance of 3D printers, the company according to Sansare is looking to tackle it in two different ways. The first option is a lease model where SMEs can lease the machine and run it for three to six months based on their requirements. Deemed as a cost-effective solution. The other is the buying model, where the printer will be priced at around Rs.10-15 lakh. ACI