BorgWarner aims to optimise commercial vehicle turbocharger technologies with next generation product lines.

Written by : John Zagone, Director Product Development & Innovation, Commercial Vehicles

& Holger Gabriel, Director Engineering, Europe Commercial Vehicles

When looking at the passenger car segment, the path to maximum electrification seems clear. For the heavy-duty commercial vehicle segment though, it is less clear. The disadvantages of a battery electric powertrain are currently still overwhelming – especially pertaining to the charging infrastructure, costs, range and payload. For this reason, commercial vehicle Original Equipment Manufacturers (OEMs) are focusing on the real-world control of criteria pollutants and on increasing the efficiencies of the classic internal combustion engine. To support these efforts, in terms of overall efficiency and hybridisation, BorgWarner is aiming to optimise its commercial vehicle turbocharger technologies. The company’s next generation High Efficiency Turbo (HET) and Variable Turbine Geometry (VTG) turbocharger product lines provide a solid performance base. They are enhanced by the eBooster® electrically driven compressor or the electrically supported eTurboTM.

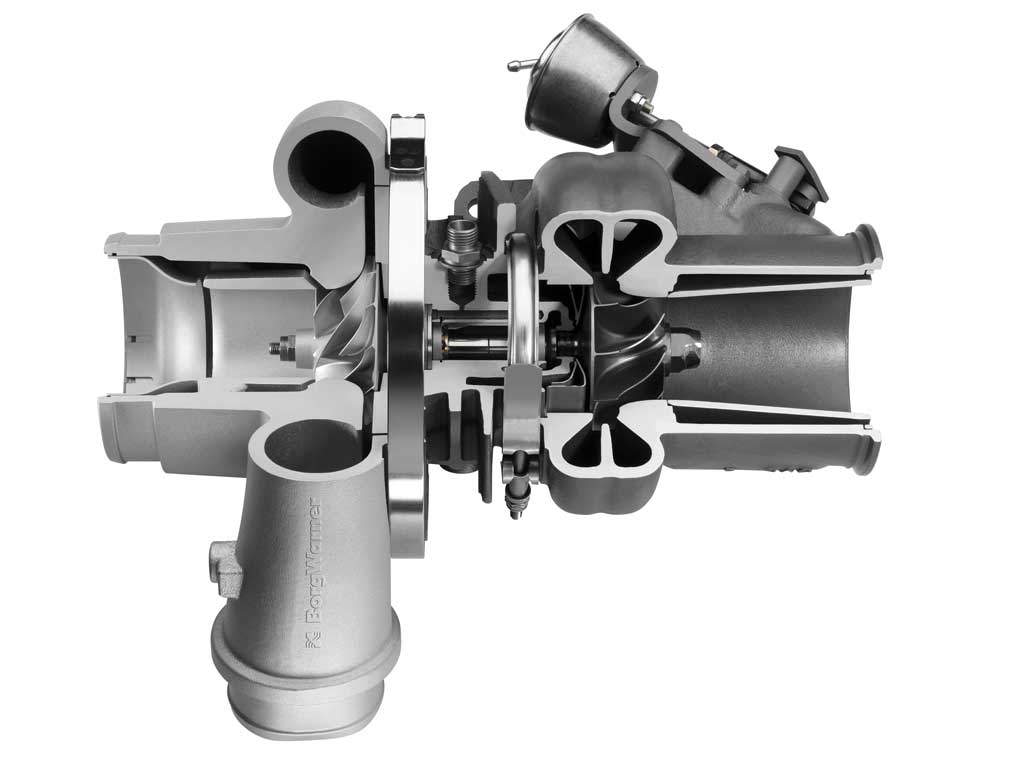

High Efficiency Turbo (HET)

BorgWarner’s HET program optimises the turbine and compressor stages with tailored map profiles. One of the technology’s key attributes: the turbine outlet design, which features a smooth conical diffuser outlet the flow from the wastegate is separated and introduced downstream of the turbine wheel outlet. The core of BorgWarner’s HET is a new ball bearing system. This was specifically developed in order to endure the challenging environment of heavy-duty applications and to enable a long lifetime of up to two million kilometres. The company’s solution enhances turbine efficiency by lowering internal friction losses and reduces overall engine friction losses by reducing oil flow requirements.

Variable Turbine Geometry (VTG)

In order to address market segments that demand not only best fuel economy over a wide speed range, but also specific power requirements and or EGR driving capability, BorgWarner has also developed a range of VTG turbochargers. The new product line incorporates the performance benefits of the new bearing system and the HET turbocharger product line, along with a VTG cartridge and turbine wheel optimised for efficiency and durability. The fourth generation of commercial vehicle VTG takes advantage of BorgWarner’s many years of experience with this technology – on both diesel and petrol engines.

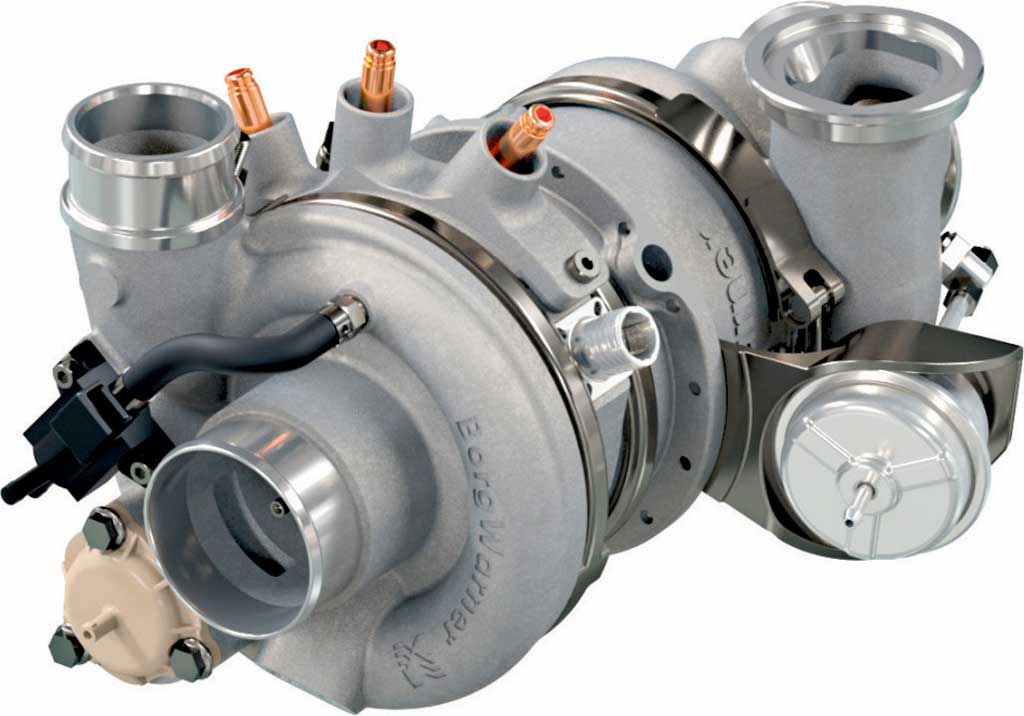

eBooster®/ eTurboTM

An electrically driven compressor, BorgWarner’s eBooster® is also available in the commercial vehicle segment in various sizes. When engaged, the advanced solution provides a large amount of additional boost to significantly improve the low speed peak torque and transient operation. When not engaged, a self-reacting bypass valve allows flow to go around the eBooster® with minimal losses. In the electrically assisted turbocharger eTurboTM, the electric drive is integrated into the conventional turbocharger. As a result, no further charging device is required. Both of BorgWarner’s systems – eBooster® and eTurboTM are based on the idea that fresh air supplied by electrical power increases combustion engine power by a factor of seven to 10 compared to an electric motor of the same size directly connected to the engine. This enables faster and more efficient transient engine operation. This advantage is supplemented by recuperation and an engine braking function for the eTurboTM solution.

Serial Hybrid Technology

For the foreseeable future, the propulsion systems of medium and heavy commercial vehicles will still be largely driven by internal combustion engines. Combined with multiple vehicle-side improvements and adapted electrification, this will still enable significant CO2 emissions improvements. A very promising approach can be the use of serial hybrid technology. This completely decouples the internal combustion engine from the powertrain and leaves the drive completely to one or more electric motors. For these concepts, the internal combustion engine, which works as a range extender, can be significantly smaller and optimised for a very narrow, stationary operating area. ACI

The views expressed by the authors are their personal opinions and do not necessarily reflect the views of the ACI magazine