o9 Solutions and operaize partner to transform manufacturing planning, scheduling and sequencing.

Story by: Deven Lad

(From Left) Sanjiv Sidhu, Chairman and Co-Founder and Chakri Gottemukkala, Co-founder, CEO, o9 solutions

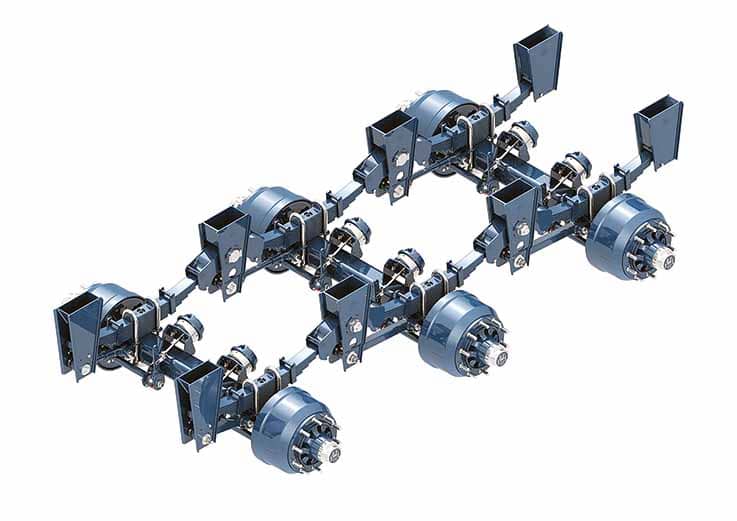

Dallas based AI-powered integrated planning and operations platform provider ‘o9 solutions’ and Germany based Software-as-a-Service (SaaS) company ‘operaize’ GmBH have partnered. The two, join hands, to deliver an integrated solution aimed at transforming manufacturing, planning, scheduling and sequencing. Averred Chakri Gottemukkala, Chief Executive Officer at o9 Solutions, “To drive higher RoI for our joint customers, o9 Solutions and operaize are integrating to transform the planning and execution of manufacturing, planning, scheduling and sequencing .” “The partnership will enable o9 customers to develop plans and cater to different time horizons across complex supply chains,” he said. In line with the strategy, the o9 planning platform will offer the most advanced scheduling and sequencing solvers.

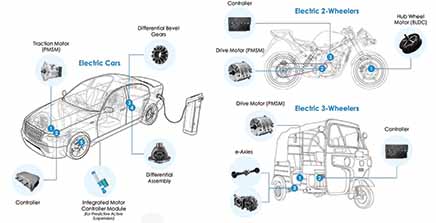

Both o9 and operaize are cloud-based, AI-powered enterprise software providers. Known to solve complex issues for numerous Fortune 500 clients, o9’s clients span across industries in manufacturing. Solutions span forecasting demand and drive better decision making in sales and supply chain. o9 Solutions offers automated capabilities for both demand and operations planning in the automotive industry. In a recent partnership, the company partnered with Pirelli, counted among the world’s leading tyre manufacturers to deploy the next-generation o9 platform.

Integrated planning

The integrated solution with connection to MES, IoT, LIMS systems, additionally brings a full overview of shop floor operations into one unique platform. This partnership will deliver concrete outcome pertaining to operating margin of the manufacturing companies. Alexander Kouril, Co-founder, and Managing Director, operaize, averred “The close partnership between o9 and operaize will allow global manufacturing clients to be offered entirely new forms of integrated planning. Most of our suppliers have adopted AI-based planning procedures and we have witnessed customers achieve increased efficiency,” he claimed.

o9 IBP solution

o9 offers Integrated Business Planning (IBP) solutions aimed at helping organisations to move from executive dash-boarding to collaborative, analytic insights-driven platform. It will aid the alignment of cross-functional plans, initiatives and resources to the changing market needs. The company also provides demand management solutions with a forecast capability. It will in turn optimise sales and margin performance of clients. Through digital supply chain solutions, complex supply chains can turn dramatically more responsive, cost-effective and reliable in turn meeting market needs.

o9 provides a single AI/ML-enabled merchandising and supply chain platform. The platform provides end to end digital intelligence with the next-generation solutions for AI/ML forecasting, merchandise and financial planning, assortment planning, size and pack optimisation, integrated allocation and replenishment. The integrated platform enables boundary-less collaboration across all retail planning modules providing an end to end, connected planning experience to execute the strategic targets and help them trickle down to the channels, customers, locations, products and sizes. It can build and manage customer-centric merchandise financial plans and improve the alignment of strategic goals.

operaize Next-Gen AI

operaize focuses on an artificial intelligence platform. The solutions offered are aimed at production and supply chain (operations). As innovators of Industry 4.0 with scientific breakthrough machine learning and AI algorithms to complex problems in production environments, the company specialises in solving complex manufacturing scheduling and sequencing challenges across industries. “Our next-gen AI proactively detects potential disruptions and autonomously and expediently determines solutions to manage the production chain,” claimed Kouril.

Using AI-based methods, proactively, the faults, risks or failures are identified. It is followed up with suitable problem-solving strategy to negate any negative effects. The focus remains on leveraging data extremely quickly and to ensure quick and effective implementation. ACI

Leave a Reply