Doing Rs.85 crore worth of business as the preference for alternate fuels grows, Greenfuel Energy Solutions is on a high growth path.

Story by: Gunjan Bidani and Deepti Thore

Recording its highest turnover this year with a business of Rs.85 crores, Greenfuel Energy is looking at a considerable uptake in business as the preference for alternate fuels rises. Recognised by Tata Motors as the Supplier of the Year 2019 for 100 per cent delivery by the spare parts division for TOC performance, the company is looking at its core competence of supplying systems that are tailor-made for an OE application. Taking pride in the fact that they have been successful in integrating various parts that support CNG system to offer good performance and reliability, Greenfuel Energy is upskilling in key areas like mechanical, mechatronics and electronics. Its area of work involving complex components that are about high pressure, low pressure, and electronics, which call for different competencies, the company is banking on technology to carve out an edge. Having a technology licensing arrangement with WEH GmbH for certain parts, according to Akshay Kashyap, Founder and Managing Director, Greenfuel Energy Solutions, it is leveraging the know-how it has gained in the Indian market to produce CNG systems that stand up to the expectations of its OEM clients as well as the end-users.

Entering the business of CNG systems in 2006 by bagging the order for Tata Marcopolo CNG city-buses for Delhi, Greenfuel Energy is planning to enter the fast-rising three-wheeler CNG business. Deriving confidence from billions of kilometers covered by the Tata Marcopolo buses with its systems on it, the company is eyeing the three-wheeler CNG segment because of an innovative EFI system that they have come out with. Patented worldwide, according to Kashyap, the innovative EFI system is currently being adopted. Any challenges that lay in its path are being tackled. Not revealing any time-line for the application of the said system, Kashyap averred that he is hoping that commercial operations will start soon. Emphasising on their participation in the OE side of the business as they found unfair practices being exercised, Kashyap mentioned that they have decided to once again look at the aftermarket, but will not play the price game. The aftermarket strategy of Greenfuel Energy this time will involve an electronic system whose serial number will have to match to be registered. Appreciating the trade practices on the OE side where the stress is on better product apart from safety, reliability, and value, Kashyap explained, “We are the largest CNG supplier in India.”

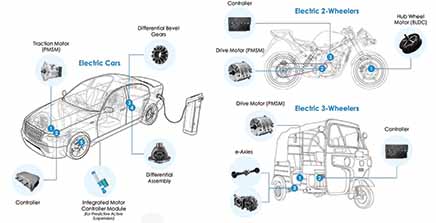

Supplying CNG systems to Maruti Suzuki, Tata Motors, Ashok Leyland, Volvo Eicher, and SML Isuzu, Greenfuel Energy is doing a good deal of development work in-house. Gaining experience from the venture, the company is stepping into the manufacture of engine-side CNG components. It refrained from any such activity until now for the lack of volumes. With the rise of awareness for quality, it now sees scope for such an activity. To be an in-house venture, according to Kashyap, the company is seeking the help of some experts to not just commercialise the components but to look at exporting it. Keen to get the assembly line up and running by March 2020, the company is currently reading prototypes. In fact, we have got some prototypes already running, mentioned Kashyap. They plan to start mass production by March 2020. Keen to increase the scope of trails, Greenfuel Energy is pursuing a zero-defect quality strategy. In no state to compromise, according to Kashyap, the attention is also on how the electric vehicle space is filling up. Making substantial investments in R&D over the last two years and having filled patents for battery design, the company is validating the same by subjecting it to extensive trials under different temperature conditions and different vehicle types. The design is also being subjected to vibration tests and more to ensure that it succeeds, and address the market needs.

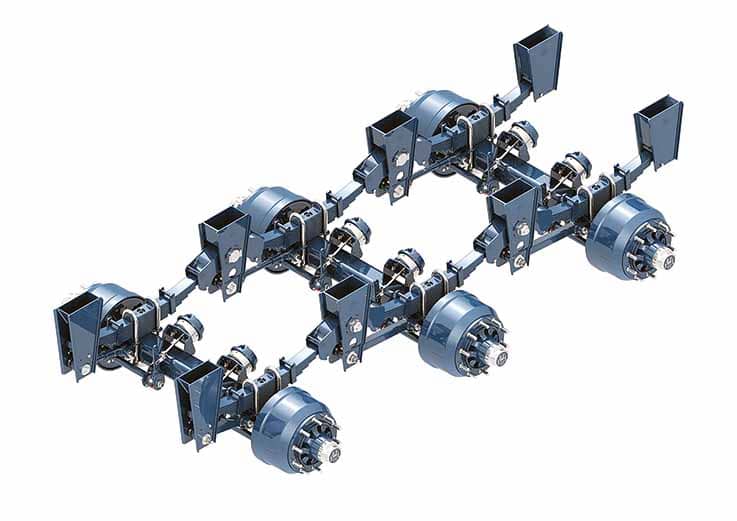

Chalking out a strategy to start exports and enter international markets, Greenfuel Energy is seeing a potential to offer systems that are cost-effective as well as reliable, unlike the systems offered by Chinese, which are cost-effective but not as reliable, or the systems offered by Europeans, which are costly but reliable. Acknowledging the fact that the Italians have been at it for a long time, and have come to build a certain reputation that is hard to overlook, Kashyap said, “We are putting a lot of stress on building our own technology.” “That is what will matter,” he averred. Stating that their focus is on technology development as it is the one which will help sustain in the face of competition from Europe and China, Kashyap averred, “We want to leverage the knowledge we have gained from working in a tough market like India and take to other parts of the world. They are certain to score since they are robust. The challenge would be to make them competitive.” Aware that stricter regulations will increase the demand on components, and the rise in electronics will make it even more complex, Kashyap opined that they are driving innovation in key component areas like a regulator. This involves mechatronics to an extent. In the three-wheeler space, Greenfuel Energy has come out with a system that combines seven components into one. It is patented and being currently promoted. A regulator injector filter to be precise, the system is the size of a palm and light in weight. It is also cost-effective as it reduces the number of parts from 13 to four.

Presenting it to three-wheeler OEMs as a component that will be a key contributor to comply with BSVI regulations on the CNG-side, Greenfuel Energy is banking on the CNG infrastructure expanding by 2025 to over 5500 filling stations. Of the opinion that they will see a lot more opportunity, Kashyap said, “Demand will not be limited for few segments, but will spread to almost every vehicle segment.” Drawing attention to the good uptake in the share of business coming from CV segments, Kashyap expressed that from 2021 the use of gas-propelled CVs will rise to 15 per cent. Stating that it is at a nascent stage at the moment, he stated, “There will be a three-fold increase in the use of gas-powered CVs.” “Even passenger vehicles will increase in the wake of the CAFE norms,” he added. Expecting two-wheelers to go the electric way, at least those that are under 150 cc, and the rest to move towards gas propulsion, Kashyap averred that he is looking at many startups arriving on the scene to create a level playing field. Because they do not carry the baggage the traditional automakers carry, startups would be better positioned to innovate and try new things, he added. Confident that the quality of electric two-wheelers is set to get much better as compared to the current ones, which run on motors that are ideally suitable for mixer-grinders used in kitchens, Kashyap said that there will arrive a need to standardise to be efficient.

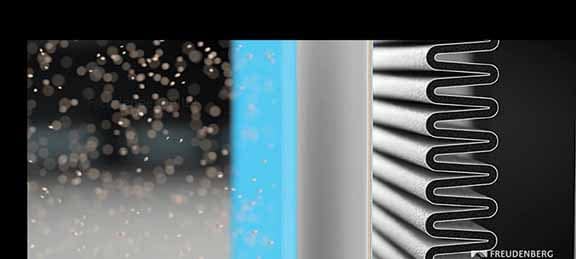

Certain that disruptions will become the new normal in the Indian auto industry hereafter, Kashyap averred that there is much opportunity in place for the Indian components industry. Pointing at the evolution of new technologies, he said that the components industry could profit from quicker adoption of technology. Providing the example of how old television technology has given way to new television technology, and how the market has come to demand it since it acknowledges the advantages of the new technology, Kashyap explained, “With volumes, cost advantages will also rise.” Terming Chinese cell suppliers as mere packers, Kashyap mentioned that the key task of producing a battery pack has been mastered by them. Announcing that Greenfuel Energy has made its battery pack, he stated that the company has made a unique modular system. “It has a unique heat removal system.” “It is made from using a mechanical packaging aluminum with fins on it for air cooling,” he added. Hoping that the OEMs pay better for all the work that companies like his are doing, Kashyap said that he is keen to see the supply chain shaping up better. Calling for higher stress on quality, he informed that OEMs like Maruti Suzuki specify international standards when one exists. Revealing that it is the cost that decides the business at the end of the day, Kashyap averred, “About 60 per cent of our business currently comes from the passenger vehicle segments and 30 per cent from Cvs.

Earning better revenue from CVs segments, Greenfuel Energy has come out with an interesting product called ‘manifold’. It re-arranges the entire filling system, which would otherwise be scattered, into a single unit that is cost-effective and worthy of ‘plug and play’. Revealing that the ‘manifold’ got them nominated by Volvo Eicher for the innovative supplier contest, Kashyap said that BSVI will lead to a rise in preference for gas propulsion. Witnessing a drop in capacity utilisation by up to 55 per cent due to the current slowdown, the company is expecting to bag a big order in the commercial three-wheeler space soon. Building a battery assembly line at Manesar in the NCR region, Greenfuel Energy is looking at a considerable play in the electric vehicle domain. Stating that they have spent some seven-crore rupees in R&D alone, Kashyap mentioned that they are looking at building technologies that they can take to other parts of the world rather than applying only in the domestic market of India. Hiring Swedish experts for a battery pack, the company is banking on technology and knowledge. Expanding its electric division by investing in manpower and equipment, Greenfuel Energy is banking on safety as it treads further; explores newer areas on the promise of technology and knowledge. ACI

Leave a Reply