Text: Anusha B

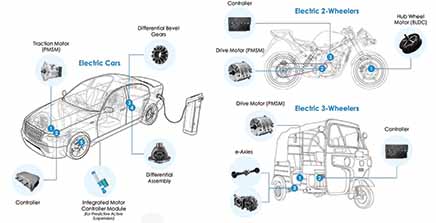

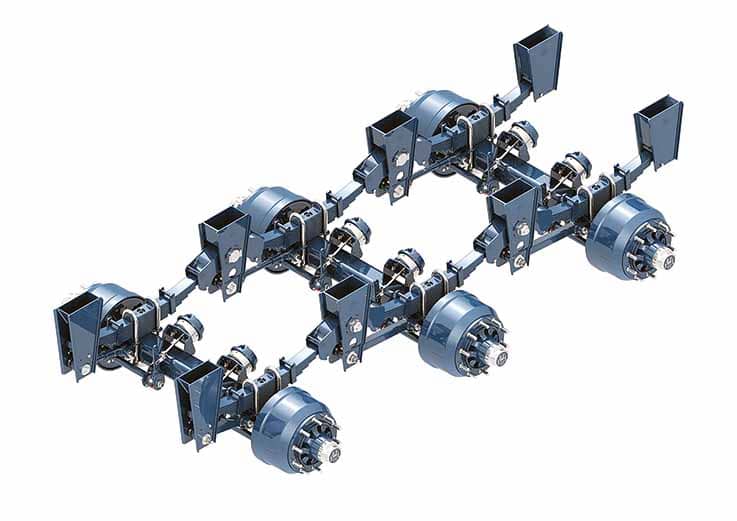

Indo Nippon Precision Components, a new venture births out of a technology wedding between Integral Component Manufacturers Private Limited (ICMPL) and Nishiura Seiko Co Ltd. The JV (Joint Venture) complements each other in an astounding way and will soon start to manufacture high precision critical engine components, transmission, gear boxes, chassis parts and other related precision components. Nishiura Seiko, a 75 year old company has an illustrious technology and the organisation is planning to have a minimum 3 years contract with ICMPL as a maneuvering move subsequently based on the outputs will look for a long term tenure.

The JV complements each other with a focus on better productivity by means of consuming the illustrative technology mentioned elsewhere. The state of the art manufacturing facility will be leveraged with the expertise of Japanese technology applied in manufacturing critical components for engines, transmission, brakes, gear boxes, chassis parts using lean manufacturing Japanese principles of Nishiura. The entire system is automated in Japan and the same will be imbibed in the Chennai facility in a sooner run with all the ground works in place.

Indo Nippon Precision Components will cater to the requirements of Japanese OEMs and other automotive components manufacturing companies for their India and overseas operations. Masatake Nishiura, President, Nishiura Seiko commented that, “Cost factor will always be put in the spot light with the design standards waving zero error and keeping both in mind quality assurance on mechanical and electrical device is committed. The assembly line in the manufacturing site will concurrently take care of 20 different machine processes which thereby optimises the cost factor. Low investment with high output and computed productive hours is the motto of ICMPL and they adhere that with a good tempo.”

Commenting on the investment Nishiura averred that, “Japan’s auto market is shrinking and to bounce back our business from this bottle neck, we have invested in India. It is a small move though will get transformed to a big hit with the contributions both from and to India. The co-operation is made mainly to cover-up the weaknesses and ACMA too fueled this move as small scale industries’ alliance will not meet the intended move unless it is manipulated in all angles. All the technical intricacies in the vehicles will be achieved with careful insights given to Tier 2 and Tier 3 suppliers. The parts supplied by them will carry with them the technical requisites of a car. Hence technology specific auto industry is not possible without active contribution from Tier 2 and Tier 3 industries.” This JV will also be working on opportunities with Indian manufacturers to implement technology related to manufacturing small automation systems to make Indian companies more competitive globally.

Commenting on the new JV, Karunakaran, Managing Director, ICMPL said, “We are delighted to partner with Nishiura, a company globally known for its high precision, quality and technological advancement in the field of automotive components, specialised machine manufacturing and complete automation. This partnership will not only integrate Nishiura’s technology with ICMPL’s manufacturing capabilities but also mutually benefit each others blue chip clientele and will contribute to India’s rapidly growing automotive sector. Nishiura is conversant in making critical components for engine and ICMPL is conversant with transmission and gear boxes. Also Nishiura is savvy in commercial vehicle segments and ICMPL is savvy in passenger car segments. Hence this collaboration will give them a harmonising and supporting move.” He further added that there are lot of stringent requirements strewing and upcoming and our country should have the hustle to capitalise on the opportunities and should shimmer amongst other countries in the league.

Japanese technology is parred with a closed loop system and everything is automated. The complete automation in the technology spots them as one up in all applied technological zones. As their business calls for zero defect, the tools, fixtures and other related components for the critical components of engine, transmission systems, gear boxes are manufactured in-house. The special purpose machines (SPM) are required for some tools manufacturing and even those SPMs are manufactured in-house. The automation process knocks not only the doors of the stages in the manufacturing process but also in the inspection arena. Hence to highlight, all the process are automated and technology used in all of these, unless taken care with high morale will jeopardise the operational activities. Japan does not fall flat on all these intricacies and waves high its success.

Japanese auto components’ manufacturing is not limited within the country’s perimeter but across the world. Voicing the occasion Nishiura uttered that, “Not to exaggerate, Japan’s in-house production is enumerated as 0.5 million whereas the production in India is identified as 16 million. This clues that the Japanese are not radius sensitive and can act and manufacture in any country across the world with their sound technical know-how.”

Karunakaran remarked, “With a planned investment of Rs 10 crore during the first year, we at ICMPL propose to send 10 of our present workers to Japan for training in special skills who in-turn are expected to train 100 new incumbents recruited for the new company. With the proposed first production beginning from December 2015, we foresee Rs 2 lakh component production per month working across 3 shifts and looking forward to augment the production to Rs 5 lakh per month with a proposed outlay of Rs 25 crore.”

The relatively competitive cost structure, availability of raw materials, skilled and qualified work force, infrastructure in Chennai are the primary factors behind which the international brands set up their manufacturing units here, opined Nishiura. Chennai is the primary export hub and the geography proclaims and supports Chennai as the largest export market. With India’s rapidly growing automotive sector, India is fore casted to become the world’s fourth largest automobile manufacturing nation by 2020 with a growth approximated to 7 million units.

Leave a Reply