Dr Shankar Venugopal, Vice President, Mahindra & Mahindra correlates the discovery of key input materials with the future of mobility.

Sustainable mobility is a key growth enabler for fast-growing economies like India. The future of sustainable mobility is being shaped by a combination of technology and business model disruptions. The convergence of electric, connected, autonomous vehicle technologies and the shared mobility business model has the potential to create sustainable mobility options for the future. These new technologies are growing exponentially in their performance and are fast becoming affordable. Leveraging these disruptive technologies and building innovative products are of strategic importance to companies and countries that wish to lead the development of sustainable mobility for the future.

The adaption of electric mobility in India will greatly accelerate when (a) the Electric Vehicle (EV)’s range improves sufficiently to remove the range anxiety of customers (b) the initial cost of acquisition of EV reduces to match the price of ICE vehicle (c) the batteries can be charged easily and quickly. As the battery pack contributes to about 40 per cent of the price of EV and determines the range of the EV, it is a key sub-system of the EV both from a performance and price perspective. The advantage of an EV arises from (a) high energy conversion efficiency and (b) the elimination of vehicular tailpipe emission.

When we build a technology roadmap for Connected, Autonomous, Electric and Shared (CASE) vehicle technology, we realise that materials hold the key to unlock a whole new world of opportunities. The number of electric cars rose from 17,000 in 2010 to more than seven million in 2019 — a 400X increase in a decade [1]. Successful scale-up of EVs critically depends on the availability of certain materials – lithium, cobalt, rare earth etc – that enable the batteries and motors for EVs. We will describe two important groups of materials that comprise (a) the battery that stores the energy and (b) the motor that powers the electric vehicle (EV).

EV battery materials

Batteries are key to the performance of EVs as they store incredible amounts of energy that can be discharged quickly, safely, and smoothly— thereby giving EVs instant acceleration, responsive handling, and fast recharging times. The key enablers that would encourage customers to adopt EVs – improving the range, reducing the initial cost and reducing the time for charging – are all controlled by the battery’s performance. EV batteries hold the key to realising scalable and affordable electric mobility.

Most electric vehicle batteries are lithium-based and rely on a mix of cobalt, manganese, nickel, and graphite and other primary components. When the first mass-market EVs were introduced in 2010, their battery packs cost an estimated USD 1,000 per kilowatt-hour (kWh). Today, we are at about USD 200 per kWh – that’s a drop of more than 70 per cent in the price per kWh in six years! EVs are forecast to cost the same or less than a comparable gasoline-powered vehicle when the price of battery packs falls to between USD 125 and USD 150 per kWh [2]. The cost of storage is expected to reach USD 100 per kWh by 2025 .

The 2019 Nobel Prize in Chemistry was awarded to John B. Goodenough, M. Stanley Whittingham and Akira Yoshino, who developed a truly transformative technology that has permeated billions of lives across the planet, touching anyone who uses a cellphone, laptop computer, electric car or any other device that is powered by a rechargeable battery. There are five primary lithium battery combinations for EVs – Lithium Nickel Cobalt Aluminium (NCA), Lithium Nickel Manganese Cobalt (NMC), Lithium Manganese Oxide (LMO), Lithium Titanate (LTO) and Lithium Iron Phosphate (LFP) – of these, NCA and NMC batteries are the most prevalent in EVs [4]. Battery cell materials include lithium, aluminium, carbon, cobalt, copper, graphite, iron, manganese, nickel, silicon, phosphorous, polyvinylidene fluoride and polyolefins. Battery pack materials include aluminium, copper, thermal management materials, thermal interface materials, steel, glass fibre reinforced polymers, carbon fibre reinforced polymers, inter-cell insulation and compression foams and pack fire-retardant materials.

An electric car with a 70 kWh battery uses 63 Kg of lithium carbonate equivalent (more than the amount of lithium in 10,000 cell phones). For every one per cent increase in market penetration of BEVs, there will be additional lithium demand of 70,000 LCE / year. Global reserves of the raw materials for EV batteries are concentrated among a few countries. 75 per cent of the world’s lithium resources are found in the region of Argentina-Bolivia-Chile. 65 per cent of cobalt production happens in the Democratic Republic of Congo (DRC). The highly concentrated production of these materials necessitates a risk mitigation strategy for a reliable supply of the raw materials to battery manufacturers. Recent research directions include lithium-air, lithium-glass, lithium-sulphur batteries; researchers have recently reported a battery formulation that can support a million miles.

Electric motor materials

The demand for electric traction motors will increase rapidly over the next 10 years, not just from the overall EV sales but also with the rise of EVs using more than one motor, specifically in premium cars and heavy-duty vehicles. Desirable EV Motor characteristics include high efficiency, high instant power, fast torque response, high power density, low cost, high acceleration and robustness. The majority of EV models use permanent-magnet motors, which are smaller and more efficient than induction motors, the common alternative. Increasing the motor performance will demand stronger magnets, which in turn will require more of the rare-earth elements. These materials typically contain several rare-earth elements (REE) such as Neodymium (Nd), Dysprosium (Dy), Praseodymium (Pr) etc. A magnet’s strength is commonly measured by its coercive force and flux density. The magnets made from the rare earth neodymium rate are the highest in coercivity and are good for high-powered EVs. The drawback of simple neodymium magnets is a low operating temperature. Adding the rare earth element dysprosium to the Neodymium increases the operating temperature. Dysprosium, along with the rare earth element praseodymium, can also increase a magnet’s coercivity, when alloyed with neodymium [5].

REEs have a very geographically constrained supply chain and a volatile price history. Whilst they are in a relatively small quantity in the motor, they can make up a very significant portion of the cost of the motor. The important materials that constitute the motor are aluminium, boron, cobalt, copper, dysprosium, iron, neodymium, niobium, silicon-steel, terbium and praseodymium [6]. These rare-earth elements like Nd, Dy are difficult to produce, as they must be extracted from other minerals via labour-intensive refinement processes. More than 90 per cent of the current production of rare earth takes place in China. Research directions include reducing the amount of REEs, formulations with alternative REEs, exploring environmental-friendly mining and refining processes, urban mining (recycling and reuse), motor architectures that do not need permanent magnets etc.

Alternative sources for critical materials

The battery materials (lithium and cobalt) and the motor materials (rare earth elements) are critical for the development of clean mobility and clean energy. Since the availability of these minerals is limited to a few locations on the earth’s crust, there is a strong need to look at alternative sources, use the available materials wisely and ensure abundant availability of the materials in future.

(a) Urban Mining – The wise use, from a circular economy perspective, of these materials involves the design of batteries and motors in such a way that the critical materials can be efficiently recycled and reused at the end of the operational life of these components – commonly referred to as Urban mining [7]. The exploration of alternative sources for these materials has also opened up two new opportunities:

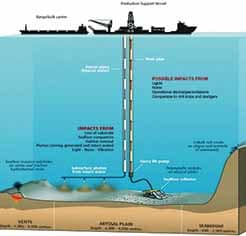

(b) Deep-sea mining – there are parts of the ocean bed (such as the Clarion – Clipperton Zone CCZ) that are rich in elements such as Manganese (Mn), Cobalt (Co), Nickel (Ni) and even a few rare earth elements (REEs) [8,9].

(c) Asteroid mining – there are many asteroids located in the region between Mars and Jupiter. Among these, the bigger asteroids with slower rotation and having an orbit that revisits Earth often are suitable for mining. Metallic or M-type asteroids (iron meteorites) are composed of up to 90% of iron, nickel and cobalt. Among the M-type asteroids, 16 Psyche, is one of the biggest and made up of iron, nickel and a number of rare metals, including cobalt [10].

Conclusion

With the rising penetration of battery-powered electric vehicles (BEV), the batteries have become the new oil. The lithium-ion battery (LIB) is the energy storage of choice for EVs. Lithium and cobalt are the two most critical elements for EV LIB. There is also a rising demand for this LIB for application in solar photovoltaics (PV).

The growing need for compact electric motors, enabled by strong permanent magnets, raises the demand for rare earth elements (REE) – Neodymium, Praseodymium and Dysprosium. These electric motors find application in EVs and wind turbines.

The growth of clean mobility and clean energy industries in the future depends on the reliable supply of critical materials lithium, cobalt and rare earth elements. We, as a community of automotive technologists, should focus our research and innovation efforts to systematically mitigate the risks in the supply of these critical materials. Self-sufficiency (Atmanirbharta) in these critical automotive materials, achieved through materials innovation efforts, can enable India to emerge as a global leader in sustainable energy and mobility. ACI

—-

Courtesy : Mobility Engineering