The official launch of India’s first retrofitted eLCV validates Etrio’s monumental focal shift on intracity logistics.

Story by: Ashish Bhatia

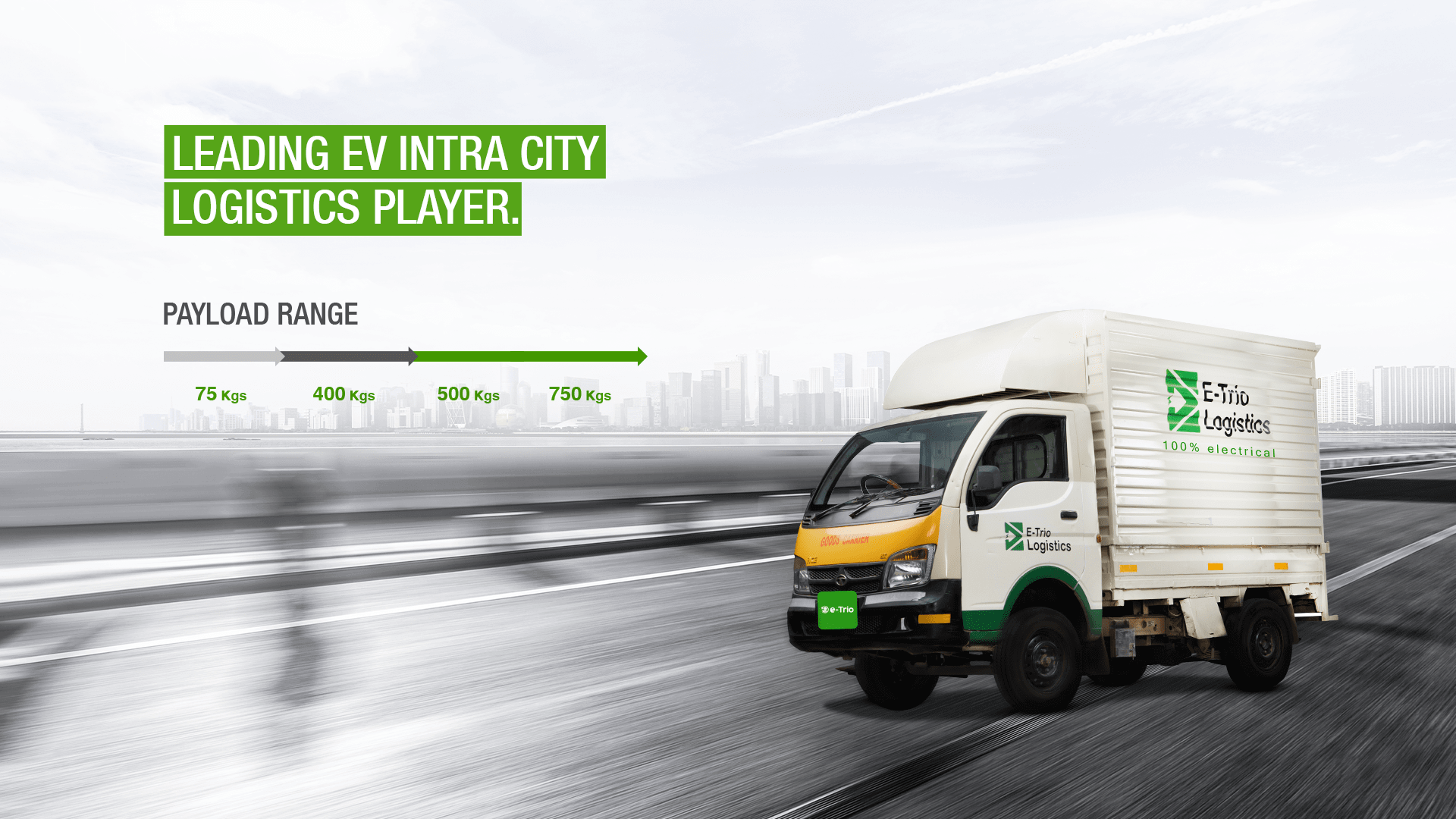

Hyderabad-based EV company Etrio is in a happy zone. A little over two years ago, the EV design organisation turned EV Original Equipment Manufacturer. Its bold step to shift focus from retrofitting Internal Combustion Engine (ICE)-powered passenger vehicles and electrifying them, to focus on becoming the leading player in the EV intracity logistics space has fructified. From building a prototype on the Tata Ace platform in 2018 to reaching the client-demo and certification stage by the end of 2019 to commercialisation in big fleets, the official launch of India’s first certified electric Light Commercial Vehicle (eLCV) is a big validation for the efforts. Averred Deepak MV, Co-founder and Chief Executive Officer at Etrio, “The mandates of the eCommerce segment to electrify their fleets was the key factor for us to shift our focus from being a product-centric design organisation to an EV OEM.” The eLCV commercialisation is our success story and the official launch is the big validation of our vision to become a leading EV player in the intracity logistics space. The e-LCV pricing starts at Rs.7.75 lacs (onroad- Delhi).

The value proposition

Claimed to be a first-of-its-kind initiative to transform and electrify intra-city logistics, Etrio, according to Deepak, has built a production capacity of 5000 vehicles annually. The company will manufacture the eLCV from a 30,000 sq.ft manufacturing facility in Hyderabad. “It is a transformational move with the capacity introduction at this level. This will not only reshape the e-commerce logistics space but also have a deeper impact on the EV ecosystem,” expressed Deepak. After all, the company is eyeing the retro fitment of over two million Tata Aces’ plying on the road. According to Deepak, the electrification exercise translates to a new lease of life for fleets with an estimated five years of life extension. The company is confident of its value proposition: lower acquisition (vs diesel), lifecycle and residual value competitiveness beating the choice of ICE-powered vehicles for plying intracity logistics. The product is claimed to have been tested and perfected through rigorous R&D work covering a distance of 1.5 lakh km. Etrio counts over 10+ leading e-commerce and logistics companies including LetsTransport, Ikea, BigBasket and Mahindra Logistics among its clientele. According to Deepak, it’s the effort to work seamlessly providing full solutions for logistic and e-commerce players including driver training, a data-driven approach backed by telematics and guidance on charging infrastructure setup that has helped the company earn the trust. For instance, Etrio Track, a telematics app, provides critical health metrics at a vehicle and component level, enables key safety features including geo-fencing, remote immobilisation and delivers data-driven insights through unique driver scorecards to drive operational efficiency. Etrio, confirmed Deepak, has received interest of over 1200 eLCVs.

Retro fitment

Etrio follows a scientific approach towards retro fitment. “We are proud to launch Etrio’s eLCV which through our scientific retro fitment process revives the earning of the driver owner by saving almost 60 per cent of the operational expenses and makes diesel guzzling LCV into a green productive vehicle,” mentioned Deepak. The vehicle selection starts with a 150-point checklist followed by stripping of the vehicle of its internal combustion parts. This is followed by mechanical and electrical retro fitment processes. It is followed up by the testing and quality inspection process, post which vehicles are rolled out for customers. The end outcome is an eLCV powered with a Lithium-Ion battery of 20 kWh on a high voltage 96V system and a certified range of 120 km. The vehicle with a rated motor power of 15kW is claimed to deliver a peak torque of 120 Nm and has a gradeability of seven degrees.

Catch excerpts of the exclusive interaction and more in-depth details in the full story to be published in the upcoming issue of the magazine.

Also read: https://autocomponentsindia.com/india-ev-manufacturing-hub-in-five-years/

Leave a Reply