IN CONVERSATION Sunjay Kapur

Q: Can you tell us about your plans to relocate manufacturing facilities? Also, what are the key aspects that you are looking at to improve efficiency and optimisation?

Q: Can you tell us about your plans to relocate manufacturing facilities? Also, what are the key aspects that you are looking at to improve efficiency and optimisation?

We are relocating to a place called Daruhera because in Gurgaon we cannot relay the lines to make them more efficient. Coming to the key aspects, I would say fishbone layout is one which gives us much more flexibility when it comes to manufacturing. It helps us bring down our cycle time. This means we can increase capacity without any extra cost. Then clubbing all the products together at one place and not having lines in different plants, which is the way we expanded.

Q: What about optimising manpower resources and the human-machine interface?

We do a lot of Kaizen. Kaizen really means incremental changes. We have got group Kaizen activities. Here, every employee of the organisation gets trained to understand what Kaizens are. Through that change, there is a fair amount of automation and improvements that we see. For example, over a period of time we have been able to build our own machines because through Kaizen activities we realised that there is a lot of involvement of the workforce. Another thing we do is machine cleaning. Every manager is assigned a machine and one day every week the person has to clean the machine. It gives interaction with the workers and interaction with the machines.

Q: What would you advice an auto component industry to do to see through this slowdown?

First thing we should do is use this time to build a better business and everybody is doing that. Build production efficiencies, kill the fat. When I say kill the fat, one should get rid of processes and practices that are adding to your cost. If you look at travel, we have really come down to zero budgets; one person travels as opposed to three people, and that too only when it is extremely necessary. This is where I would rather cut cost rather than getting rid of people.

Q: What have been your learnings from the Deming Award that you won?

It took us five years to get to Deming. It is a five-year process where you really improve your quality systems. It is management as a science. We were the first steering manufacturer in the world to get the Deming Award. And we got it 10 years ago. We had to create a mindset which was quality oriented. Between 2009 and this downturn, productivity had increased tenfold. Because of that production pressure it was easy to lose focus on quality. But the quality system and quality drive is very strong in our company and that is something that Deming has really taught us.

Sona Koyo starts Skill development Institute in Gurgaon

Sona Koyo starts Skill development Institute in Gurgaon

Sona Koyo Steering system is focusing on skill development and has extended its skill building capability by setting up a new training center at its Gurgaon plant. This is in addition to the training programme running at Nagina, Mewat district. Sunjay Kapur, Managing Director, Sona Koyo Steering Systems says the new institute is part of their CSR with close to 80 percent of students being absorbed by industry. By engaging professionals from industry the institute is expected to fill up the gap between industry requirement and training courseware. There is a lack of congruence between industry needs and the programmes set up by academia but this will be corrected now so that the right type of skills are imparted to students. The institute is expected to train over 4,000 students and nearly 1,000 employees of Sona Koyo over the course period of three years. It will also offer courses of month long duration.

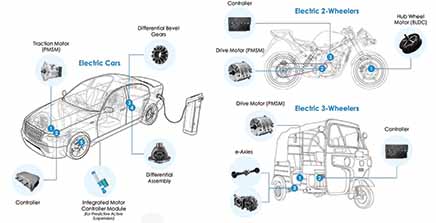

Steering on the other hand supplies C-EPS to Mahindra and Tata Motors.

Sona is also part of another company called Sona Fuji Automotive Limited with Fuji Kiko (a part of the JTEKT group). Sona here owns 51 percent whereas Fuji Kiko controls the rest. The company has now also diversified into pressure die-casting and sheet metals, which started as a captive division but is now looking towards expansion.

While the overall industry has been slackening, Sona Koyo has performed well. In the Q2 results in FY13-14, the company reported a Rs 12.62 crore profit, up from Rs 6.94 in the same period the year before. Even its stocks have performed consistently ever since. The company has also been able to save on material cost, which is its largest cost, through localisation programme. The focus is also on bringing down the manufacturing cost so as to build a more efficient business.

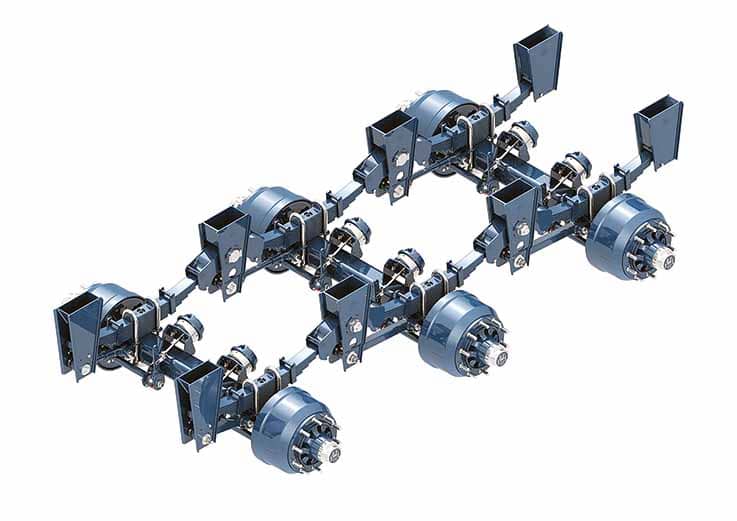

The company will also re-locate most of its operations from Gurgaon to a place called Daruhera which is just 35 km from the current location. It is also moving some equipment to Sanand and Chennai. This is primarily for manufacturing optimisation since a lot of processes have changed and become more sophisticated.

“2013 experienced timely and good monsoons, which translated into higher production and better farmer sentiments.”

The company has also been able to save on material cost through localisation programme

The company has also been able to save on material cost through localisation programme

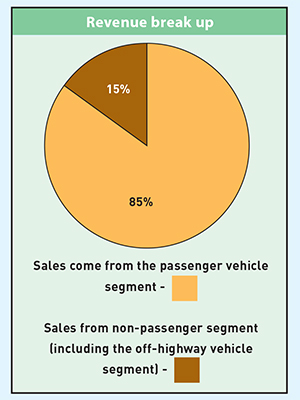

The company’s pursuit of garnering market share in the off-highway segment is bolstered by its much acclaimed Electronic Power Assist Module (EPAM), a patented technology. Sona Koyo has already made an announcement about investments into EPAM and farm equipment to the tune of Rs 50 crore. John Deere, a Fortune 500 company known for manufacturing farm equipment, is one of the clients of this technology.

Kapur added that the company is banking on EPAM to widen its export base as it is pre-dominantly for the export market. As far as the EPAM product is concerned, they are focusing on the United States. He also said that he is open to acquisitions, collaborations and other avenues for growing the export base, without giving any specific details.

The company has exited from its venture with Fuji Autotech, Europe which had given it a presence in Eastern Europe and South America. This was because it was only a minority investment made earlier to create an export market for their components. Since they felt they had achieved what they wanted to get out of the partnership they pulled out just a few months ago.

In fact, with growth likely to make a comeback in the US, most auto component manufacturers are eyeing that market to compensate for the falling domestic market. The companies exporting to the US have done very well in the current year and this is an area that most other companies would be looking at. Sona Koyo has 10 percent of its revenue coming in from direct exports over and above indirect exports through OEMs. ACI

Story & Photography: J Srikant

Leave a Reply