The rings undergo a demagnetizing process through which magnetized dust is removed. If any unwanted particulate remains on the rings, they are removed during the washing stage, which happens next. This also helps in maintaining the vibration level of the Packaging bearing.

It is here that the outer ring is moved to the same line as the inner ring for pairing. The balls are filled up after the inner and outer rings are clubbed according to size. It is followed by caging and riveting, which are the final stages of manufacture. The entire bearing now undergoes thorough washing and checking for missing components and vibration. Drying mechanism removes the residual washing medium, which is the white spirit. The bearings are then marked with the type, date and time of manufacture and the plant from where it has been manufactured, and sent for preservation (with oil) and sealing. After the final visual inspection of each and every unit, it is sent for packaging.

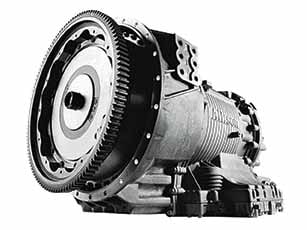

Taper Roller Bearing Channel

The process that is followed is almost similar to the one followed in the DGBB channel. The major difference between the two, however, is the roller filling operation. While on DGBB channel the balls are filled first and caging then done, at TRB channel the rollers are filled and the cage is fitted alongside at the same station. The other difference in TRB manufacturing is that it has no shared processes like in DGBB and HUB channels. The face and OD grinding is done on the channel itself. Due to this, there are 3 additional machines operating on this channel.

HUB channel

There are primarily five parts in a Taper HUB namely inner ring, outer ring, cage, ball and seal to prevent contamination.

The Hub bearing channel resembles nothing short of a mini-factory in itself as the bearing is manufactured right from its raw form to finished product on this one single channel. Earlier it was a batch production that SKF used to follow, but now it is a one-piece flow. The channel is fixed and maintained with poke yokes in place for mistakeproofing at every station.

Both the inner and outer rings are processed in parallel on different lines and then brought together for assembly. The first process is face grinding. It is one of the most important during manufacturing as this process gives the bearing its main characteristics and ensures perfection during fitment. The inner ring moves on for track grinding which is succeeded by super finishing which is also called the honing process.

Also, the outer ring is face ground and OD ground in the shared operations. The outer ring goes through track grinding and honing. According to the process control plan, the inner and outer rings are sorted as per the requirement of the customer and then go through a rigorous testing process. After this, the grease is filled into the bearing. The right amount of grease is filled by checking the weight before and after filling. The final product is checked for its width and bore size, and visual inspection is done to check for any deviations before packing.

Dispatch

Kushal – The Multiskilling Facility

To help improve the skill sets of the workforce, SKF set up its first training centre in India – Kushal, 3 years ago, for multi-skilling the workforce and making it shopfloor ready. Based on the ‘We Care’ principle of SKF, the success of this centre has already inspired similar training centres by other group companies at their own plants. A new entrant has to go through a 12-day training to improve upon safety, quality and delivery before he can enter the shopfloor. The training is done at various skill stations which are designed based on the exact process which happens during manufacturing.

DGBB HUB1

The smooth and efficient operations at this half-a-century old plant, leads us to believe that there are constant improvements -Kaizens, which are implemented here to reduce monotony and tiredness of the employees and to make the process more efficient. One example is the design change in the trolleys which are used to move material inside the plant. Earlier, the grab-rail of the trolley was located at the bottom, near the wheels, so the worker had to bend every time the trolley was to be moved. The company mapped the movement of the worker and found that a worker had to bend 2,100 times a year. To reduce the fatigue level of the worker, the handle was moved up so that the worker does not have to bend to pick up the grab rail.

A walk through SKF’s Pune plant is a sure-shot lesson on how to mould a mammoth manufacturing setup according to changing times and improve operations by bringing in newer technologies to implement better quality standards.

Leave a Reply