Text : Bhargav TS

Force Motors inaugurated its all new, state-of-the-art engine assembly plant in Mahindra World City near Chennai. The Rs 200 crore plant that caters to BMW India is the first independent plant outside of the BMW Group that assembles and tests engines for the German luxury car maker. The project work began in June 2014, got completed in a record time of 7 months. The Chennai facility will assemble inline-4 and inline-6 cylinder engines for the locally made BMW cars such as the 3-Series, 5-Series, 7-Series, X1, X3, X5 and 3-Series GT. The engine assembly and testing at the plant is carried out in accordance with BMW’s global standards.

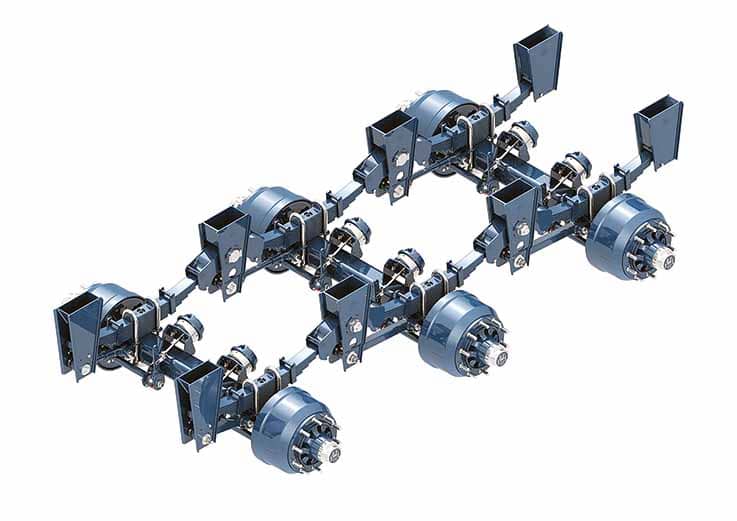

“Global top brands like BMW and Mercedes Benz entrusts the engine manufacturing with us shows their confidence on us and re-instills our capability in our minds,” said Prasan Firodia,Managing Director, Force Motors. He further said, parterning with BMW is an important milestone in our company’s journey. We envision this facility will be instrumental in further establishing Force Motors’ strengths as a preferred supplier of critical and high precision components to top European brands. Apart from BMW we are also assembling Mercedes Benz engines and axles for all its C, E, S and M class cars and SUVs built in India at our Urse plant.”

This facility will take care of material inspection, temperature, dust and humidity control. All the equipments used for production will be computer controlled and are directly connected with the main plant of BMW. The plant has a capacity to produce 20,000 engines every year and the capacity can further be increased to 50,000 units as well. With the IT system in the production facility of Force Motors integrated in real time with BMW’s global production network, all essential production process values can be integrated in BMW’s global data. The plant is equipped with the latest technology for ensuring assembly and joinery processes with computer controlled precision equipment. The plant also contains most modern engine testing equipment which tests 8 engines in 120 seconds with a negligible 100ml fuel consumption.

Apart from the new BMW plant, Force is now setting up a brand new modern plant for Mercedes Benz at Chakan in Pune. The plant is expected to come up by the end of this year. Force Motors is concentrating on contract manufacturing businesses to drive revenue for the company. The company is expecting to triple its revenue from the current Rs 1000 crore to Rs 3000 crore over the next 3 years. So far the company had supplied over 50,000 engines to Mercedes Benz since its forged a partnership with Mercedes Benz

in 1997.

Firodia added that the Tamil Nadu Government’s single window clearance approach is commendable as we were able to incorporate the entire facility set-up in 7 months. This facility is realised with an encouraging support from Mahindra World City management, Tamil Nadu Government, civil architects and our inhouse management. With this facility successfully commissioned we have 15 facilities put together across country. We are also in a plan to commission 2 more plants, one in Dewas, Madhya Pradesh and another in Gujarat to manufacture aluminum die castings.

The cars are more efficient with 3,4 and 6 cylinder engines and having outsourced our engine manufacturing to Force Motors, Ralf Hattler, Global Head Powertrain, BMW remarked that, “The BMW cars rolling out of Chennai plant since January 2015, have been fired with Force Motors engines. Force Motors engines comply with our quality standards and cleared the tests at every stage. Not to aggrandise the Force Motors engines sets new yardsticks for us and delights our emotional needs too and as a company we are very much impressed with their deliveries and commitments.”

India has always been a supportive market and BMW make cars in India by increasing its localisation to 50%. “We prefer Indian market for optimising our cost and give our cars a value addition with technology standards and we keep pushing our operations in India. Our technologies have bagged many awards, accolades and trophies and we pocketed the ‘National Engine of the Year’ award too which gives an obvious answer on how do we imbibe technologies in our products and the compatibility standards our products endorse. Together with Force Motors we produce best in class premium products,” underlinesHattler.

BMW is a custodian for brands and quality plays a cardinal role and it is one of the keys to success. The company is going to celebrate its centenary next year and this is a significant milestone for an automobile company to achieve. Unless the company is innovative and technology driven this milestone would not have been realised. Driven by its performance and innovation the company is now contemplating much on the technology standards to be incorporated in their vehicles for better fuel efficiency and benchmark emission standards.

Leave a Reply