As technology advances there is a huge demand for performance engines and cooling is crucial in heat dissipation. Ashish Bhatia with Prateek Pardeshi looks at the advances in air-cooled systems led by fins.

Heat dissipation is crucial to the efficiency of an Internal Combustion Engine (ICE). Especially since temperatures are known to breach the ~2300-2500 degrees Centigrade mark. Here, the role of air fins is crucial. The fin as an extended surface is used to direct the heat away from the engine back into the atmosphere. Failing which, in an uncontrolled environment, one risks burning the oil film between the moving parts. It may result in seizing the engine forcing the vehicle to enter the limp mode. With efficient cooling, the temperature can be brought down by up to 150-200 degrees Centigrade. Forming an essential component of air-cooled systems, fins can be spotted easily in two-wheelers in close proximity to the engine heads and the engine blocks.

Heat dissipation is crucial to the efficiency of an Internal Combustion Engine (ICE). Especially since temperatures are known to breach the ~2300-2500 degrees Centigrade mark. Here, the role of air fins is crucial. The fin as an extended surface is used to direct the heat away from the engine back into the atmosphere. Failing which, in an uncontrolled environment, one risks burning the oil film between the moving parts. It may result in seizing the engine forcing the vehicle to enter the limp mode. With efficient cooling, the temperature can be brought down by up to 150-200 degrees Centigrade. Forming an essential component of air-cooled systems, fins can be spotted easily in two-wheelers in close proximity to the engine heads and the engine blocks.

According to a Lap Lambert Academic Publishing, a paper authored by Sathishkumar Kuppuraj of Elgi Equipment Ltd. from the technology department writes on the engine high temperature and how its subjected to high-degree, thermal stress. He cites fins as the only component used to dissipate the engine heat. “Fins are generally used to increase the heat transfer rate from the system to the surroundings,” he explains. In his study, he further cites how computational flow analysis, on the engine cooling fins helps determine the heat dissipation rate and the principle implemented to increase the heat transfer rate. In a noteworthy modification carried out, fins were modified using different notch types and made up of the same material. Kuppuraj stresses on the need for knowing the efficiency and effectiveness beforehand to be able to ensure a proper design. The analysis was conducted using the ANSYS – CFD Fluent software, in this case (read the detailed cover story on ANSYS with an exclusive upfront interaction in our upcoming issue to learn more about the advancements in simulation). The study is known to have made use of fins with holes, fins with a V-shaped notch and fins with a rectangular notch.

In another interesting case study, experts have argued over the architecture of single-cylinder engines being more efficient than multi- cylinder engines. In the case of the former, for instance, the airflow is directed all around the sides of the cylinder, making cooling far more effective. The drawback is, that most single-cylinder engines are petrol engines and do not fit the requirements of diesel, heavy-duty vehicles. Especially since diesel has a newfound identity as “clean diesel”. These are however extended to three-wheeler duty cycles. The amount of heat dissipation, however, depends on two crucial factors: the amount of airflow through the fins and the fin surface area.

Fins are known to have a high thermal conductivity. It is this conductivity that allows it to conduct the excess heat through the fin wall. It provides the added capability of an increase in the convective and radiative heat exchange. The cool air is forced through the fins by the fans, and in air planes and automotive, this is determined and often made possible by the speed of the vehicle. Be it on the radiator, the engine block or the engine head, they primarily help increase the surface area known to be in direct contact with the ambient air. Simply put, when cast or bolted to the flywheel, it acts as a fan blade for enhanced air circulation.

Fins are known to have a high thermal conductivity. It is this conductivity that allows it to conduct the excess heat through the fin wall. It provides the added capability of an increase in the convective and radiative heat exchange. The cool air is forced through the fins by the fans, and in air planes and automotive, this is determined and often made possible by the speed of the vehicle. Be it on the radiator, the engine block or the engine head, they primarily help increase the surface area known to be in direct contact with the ambient air. Simply put, when cast or bolted to the flywheel, it acts as a fan blade for enhanced air circulation.

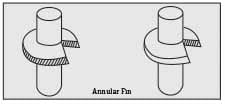

Indian suppliers like Delhi-based KBA Metal Products Pvt. Ltd. and Chintamani Thermal Technologies Pvt. Ltd. from Chakan operate in the domain. They encompass different types of fins spanning straight fins of uniform cross-section and a non-uniform cross-section, annular fins, cylindrical fins and pin fins. The straight fins have an extended fin attached to a wall. The annular fin is attached circumferential to the cylinder head. The cross-section is known to vary from the centre line of the cylinder. It is further divided into rectangular and conical profiles. The pin fin is a cross-sectional profile wherein the diameter is known to be smaller compared to its length. It may be of both uniform and nonuniform cross-sections. The material used for the pin plays a significant role here, and aluminium continues to be a choice with a growing interest owing to its chemistry. Low density and the ability to resist corrosion are the prime factors for its consideration. It also scores high on electrical and thermal conductivity. As a ductile metal, it has a low melting point and density. Notably, the study concludes with the consideration that fins with rectangular notches are far more efficient compared to V-shaped fins and fins without notches. We spotted a Royal Enfield Classic 500 fitted with rubber spacers on cylinder fins. As per riders, while it is a good sound damper, there are critics questioning the heat dissipation transfer, leaving scope for further evolution.

Fins in EVs

Fins are not restricted to ICE only. These are also used in industrial engines and motors. In the case of Electric Vehicles (EVs) two-wheelers, these can be found on the motors. For instance, Ather uses a 6 kW permanent magnet synchronous motor designed to deliver 26 Nm of torque. To ensure heat is dissipated, the two-wheeler deploys annular fins. An annular fin transfers more heat than a similar pin fin at any given length because of the increased surface area increasing the distance to the object. Annular fins are frequently used in liquid-gas heat exchanger systems to increase the heat transfer rate. It is noteworthy that an increase in the per centage of wetness on the fin area has an inverse correlation to the fin efficiency given that the temperature gradient increases.

Fins are not restricted to ICE only. These are also used in industrial engines and motors. In the case of Electric Vehicles (EVs) two-wheelers, these can be found on the motors. For instance, Ather uses a 6 kW permanent magnet synchronous motor designed to deliver 26 Nm of torque. To ensure heat is dissipated, the two-wheeler deploys annular fins. An annular fin transfers more heat than a similar pin fin at any given length because of the increased surface area increasing the distance to the object. Annular fins are frequently used in liquid-gas heat exchanger systems to increase the heat transfer rate. It is noteworthy that an increase in the per centage of wetness on the fin area has an inverse correlation to the fin efficiency given that the temperature gradient increases.

Leave a Reply