Rahul Jain, director and J K Jain, CMD – Fiem Industries

Rahul Jain, director and J K Jain, CMD – Fiem Industries

The company has lately commenced headlamp supplies to Harley Davidson, India, which is also exported to other manufacturing locations of the OEM. For Honda, it is supplying almost all the lamps for its new global two-wheeler. It exports to 11 worldwide destinations including Japan, Korea and Thailand.

Fiem supplies LED tail lamps and blinkers to almost all two wheeler OEMs except HMSI. Rajesh Sharma, executive director (marketing & development), Fiem Industries, said the company recently commenced supplies for one model of HMSI and hopes to expand supplies of tail lamps for all models soon.

Globally, OEMs are working with lighting system manufacturers to introduce LED headlamps in two-wheelers by 2015 or 2016. In three years costs for twowheeler LED headlamps has dropped to Rs 2,500 from Rs 6,000; however, it has to compete with conventional lighting that is about one sixth the present cost. A few LED bulb manufacturers including Philips and Osram are working to meet this requirement. Sharma affirms the LED headlamp prototypes have been successfully tested and FIEM is talking to a few vehicle manufacturers for commercialisation. At present LEDs are confined to the position lamps supplied to TVS Motor and Mahindra for two wheelers.

Sharma continued that optimising optics and dissipation of heat are two issues in developing LED lamps. Three mockup samples have passed the homologation requirements, he said. Earlier, two bulbs with one watt each were deployed for high and low beams. The company’s research has enabled it to use only one bulb of one watt coupled with a motorised tilting shield, which facilitates to control symmetrical beams adhering to high and low beams. Currently it is supplying license plate LED lamps to Honda Cars and trunk lamps to Hyundai Motor India. The company offers warning triangles to almost all the OEMs, supplies LED displays to Tata Marcopolo, and is developing tail lamps for Ashok Leyland-Nissan Dost.

Sharma continued that optimising optics and dissipation of heat are two issues in developing LED lamps. Three mockup samples have passed the homologation requirements, he said. Earlier, two bulbs with one watt each were deployed for high and low beams. The company’s research has enabled it to use only one bulb of one watt coupled with a motorised tilting shield, which facilitates to control symmetrical beams adhering to high and low beams. Currently it is supplying license plate LED lamps to Honda Cars and trunk lamps to Hyundai Motor India. The company offers warning triangles to almost all the OEMs, supplies LED displays to Tata Marcopolo, and is developing tail lamps for Ashok Leyland-Nissan Dost.

In order to enhance quality the company is installing a robot to inspect every printed circuit board of the LED lamp’s driver unit. In addition, it will select the bulbs based on the required view angle (between 120 and 130 degrees), which is key to maintain the level of beams. To be installed in few weeks, the robots will also enable assembly of LEDs based on the inherent angle, eventually optimizing the light output.

In addition to lighting, Fiem Industries is also in to plastic parts and mirrors. This division has two plants in Tapukara to make ABS and PP plastic parts, supplying to HMSI. Recently it has commenced supplies of few parts including fenders and windscreen to Suzuki Motorcycle India Limited. The company’s Hosur plant supplies rear fenders, blinkers and number plate lamps to HMSI’s plant in Narasapura, near Bangalore. Fiem Industries has recently received letter of intent from Suzuki in Indonesia. It is also likely to supply to Yamaha in Vietnam and Thailand soon. These will be direct exports, he adds.

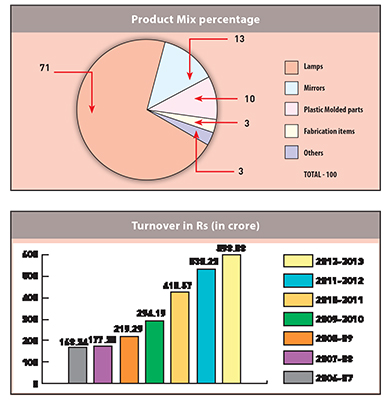

Despite auto industry reeling under severe slowdown, Fiem’s presence in varied segments and especially in two wheelers has given a breather now said S Narayanan, Head (commercial & international operations), Fiem Industries. The company’s diversification in to two more segments – LED Luminairies (for indoor and outdoor applications) and LED display and integrated passenger information system (for buses and railways) has begun paying dividends. These two segments will supersede the sales performance of automotive segment soon, he said. ACI

Story : T Murrali

Leave a Reply