Sona Comstar continues to sign on strategic partners and bridge capability gaps. Ashish Bhatia with Deepti Thore looks at the equation to offer sustainable and cost-effective emobility solutions.

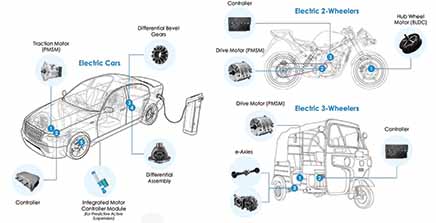

Sona Comstar, a supplier of vital automotive systems and components to automotive OEMs is also a big supplier of the burgeoning emobility segment. The company, naturally, has been on the hunt for strategic collaborators wherever deemed fit to acquire technical capabilities. In line with the strategy to become a one-stop automotive technology solution provider to manufacturers both in the domestic as well as global markets, the company recently signed on with Enedym Inc. (Enedym) based out of Hamilton, Ontario in Canada with an aim to licence the latter’s technology for application in three-wheelers, high-performance electric motorcycles and four-wheeler cargo delivery EVs basis the power range. Previously it is known to have signed on with partners like Israel based IRP Systems for joint development and localised manufacturing of magnet less e-motors and controllers aimed at the electric two-wheeler and three-wheeler market in India. It is with the focus on offering sustainable and cost-effective emobility solutions to its customers.

Drawing attention to the tier1 segment of the industry as a whole, Sunjay Kapur, Chairman, Sona Comstar and President, ACMA India, on the sidelines of an ACMA summit expressed, “We started our lives with joint ventures and with licence agreements and very quickly we were able to adapt or adopt that technology. Some of us have exhibited joint ventures and continue to build on the technology that we learned from our partnerships.” According to Kapur, the tier2 and tier3s in the supply chain will have to invest in technology, whether it be through a joint venture or licence agreements, or other methods of bringing technology to our country. Having said that, the company is particular about owning technology in a bid to continue experimenting until it gets it right, asserted Vivek Vikram Singh, Managing Director (MD) & Group Chief Executive Officer (CEO) at Sona Comstar in the company’s earnings call.

Push for e-mobility

Having a diversified presence across geographies, Sona Comstar has spent an aggregate of Rs.1,563 million (including Comstar) on Research & Development over the past three years, including an investment of Rs.915 mn in FY2020-21, at an estimated 5.8 per cent of its total revenue. The focus on driving the electrification of vehicles by supplying a range of components and solutions for the Indian two-wheeler and three-wheeler EV market in order to stay ahead of the curve, as an early mover is evident from the recent strategic partnerships. This strategy has fructified with EVs contributing to 23 per cent of the revenue in the first nine months of FY22, a 168 per cent YoY growth. With 24 EV programs across 14 customers globally, the company has been able to tap markets like North America, Europe and Asia. In the net order book, EVs contributed 66.4 per cent of the net revenue at Rs.116 bn as in the third quarter of FY22 (Q3 FY22).

Take for instance, the partnership with Enedym, to produce magnet-less EV motors. Referring to it, Kiran M Deshmukh, Group CTO at Sona Comstar stated in a company release, “This partnership opens doors for us to the inventions developed by Dr Ali Emadi and his research group at the McMaster Automotive Resource Centre, McMaster University.” Dr Ali Emadi, Founder, President, and CEO of Enedym is known to have stated, “This collaboration will effectively bridge the gap in supplying next generation SRM motor technologies by Enedym, which require no rare earth metals, reduce cost significantly through advanced digitisation, and achieve class leading performance, with a trusted and highly capable partner, Sona Comstar, to supply highly engineered automotive systems and components to OEMs.” He also pointed at electric three-wheelers being at the forefront of the vehicle electrification transition in India and, therefore, expectations being fair of the combined efforts having a significant impact both in terms of sustainability, efficiency, cost reduction, and performance improvements.

As per the agreement, both the companies will develop Switched Reluctance Motors (SRM), electric propulsion and electrified drivetrains suited to Indian duty cycles of the partnerships’ target segments. This entails systems for a peak power range of 10-30kW for three-wheelers, 10-20kW for two-wheelers and 10-40kW in case of the four-wheeler cargo SRM drive systems. Given that Enedym will licence its SRM technologies to Sona Comstar for manufacturing the drive motors, controllers, and drivetrains for the target applications exclusively in India, one can expect the serial production of these systems to commence in 2023. Notably, the elimination of permanent magnets promises to help Sona significantly lower the cost of propulsion motors. Add to it, the simplified structure is expected to deliver higher efficiency at high speeds, fault-resistant operations that are deemed suitable for operating in harsh environments, especially at extreme high-temperatures.

In another strategic partnership that took shape in July 2021, Sona Comstar with Israel’s IRP Nexus Group Ltd. signed on to develop, manufacture and supply magnet-less e-motors and controllers for the electric two- and three-wheeler platforms. Under the agreement, IRP will licence its technology to Sona Comstar for manufacturing of the system exclusively in India. The company expects mass production to commence under the partnership, in 2023. The collaboration of IRP’s control technology and Sona Comstar’s state-of-the-art manufacturing capabilities, and global reach is expected to further promote mass electric mobility. IRP has implemented its ‘TrueDrive’ technology in the magnet-less e-motors. “The system developed through this partnership will be an environmentally compatible and cost-effective solution that would ensure the security of natural resources by avoiding the use of rare earth elements,” reiterates Deshmukh

Sona Comstar recently launched its ‘Motor T’ family of motors and controllers said to have been developed inhouse. As per company claims, ‘Motor T with an optimised controller’, with next generation technology, has the highest efficiency (96 per cent), power and torque density in the 48V category in the world. With Motor T (HS), the company will cater to the high-speed two-wheelers and with the Motor T-72, it will cater to high-speed and long-range two-wheelers. Notably, in Motor T-REF (RareEarth Free), the company is known to have used ferrite magnets eliminating the use of Neodymium magnets. Being at a nascent stage, the projections on the market and revenue of the Motor T family are still some time away. It’s moves like these that are enabling Sona Comstar to bridge capability gaps and own its technology offerings to the market. ACI

Also read, With ACMA Leadership

Leave a Reply