Amara Raja Batteries has partnered Gridtential Energy to assemble and test advanced bipolar lead-acid batteries aimed at electric and hybrid vehicles.

Story by: Deepti Thore

The next generation of batteries already developed or being developed is aiming to outdo the previous generation batteries broadly on fronts like charge capacity, charging speed and battery life. All of this while also being cost-efficient. A significant upgrade is the deployment of bipolar battery technology. Bipolar battery advantages over the previous generation include uniform current density, increased active material utilisation, higher energy density, higher power density and simpler construction. Looking at its potential, Amara Raja Batteries Ltd., and Gridtential Energy Ltd., have partnered under a ‘Technology Evaluation Agreement’. Amara Raja and Gridtential Energy in a joint effort will assemble and test the Silicon Joule™ bipolar reference batteries using the former’s active material to test it on fronts like cycle life, energy density, battery efficiency, charging rates and manufacturability. Averred John Barton, Chief Executive Officer, Gridtential Energy, “We believe that Silicon Joule advanced lead battery technology is a perfect fit for the Indian market, offering a high-performance and a low-cost solution.”

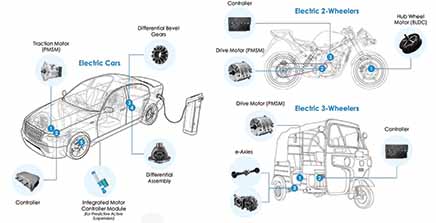

Gridtential Energy, the inventor of Silicon Joule™ provides non-exclusive licenses. The technology is expected to find application in hybrid-automotive, Low-Speed Electric Vehicles (LSEV) and Energy Storage System (ESS). It is aimed at enabling manufacturing partners to effectively equip their factories to churn out the battery in 24V and 48V variants. To put things in perspective, the 48V battery market for hybrid vehicles alone represents a USD 30 billion opportunities worldwide with the backdrop of 12V electrical systems found to be strained with mechanical operations associated with car and truck models. The former is said to provide the firepower for hybrid automotive features, such as stop-start energy regeneration and engine shut-off at higher speeds. Manufacturing partners can look forward to upgrading sans any giga-scale capital investments as per claims made. Expressed Jayadev Galla, Vice-Chairman and Managing Director at Amara Raja Batteries Ltd., “As an organisation committed to innovation, entrepreneurship and pursuit of excellence, Amara Raja is always interested in exploring new ways to serve our customers with advanced products.” “The unique Silicon Joule™ bipolar technology from Gridtential holds significant potential to deliver enhanced value to our customers. And very importantly, Gridtential helps meet our environmental commitment based on lead battery recyclability greater than 99 per cent,” he opined.

Bipolar battery technology

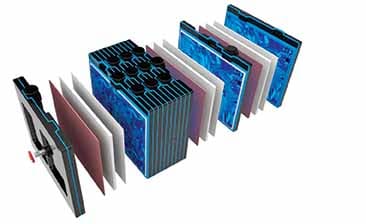

According to S. Vijayanand, Chief Executive Officer, Amara Raja Batteries Ltd., bipolar battery technology has the potential to bridge the gap between current lead-acid batteries and the increasing demand for new energy storage applications. Silicon Joule™ bipolar technology is claimed to enable an innovative class of advanced lead batteries with silicon at its core. The design-driven, low-cost, high-performance, patented energy storage solution is claimed to provide an improved power density, cycle life, dynamic charge acceptance and wider temperature range. Weight reduction of up to 40 per cent due to a novel-stacked architecture, while retaining full lead-battery recyclability are among added advantages. The weight-reduction is attributed to the elimination of lead grid and strap material. The cycle life, for instance, is claimed to improve from a 3x margin to 5x. It is also claimed to improve the Dynamic Charge Acceptance (DCA) from a 3x margin to 10x. Besides the operating temperature extends by an estimated 10 degree Centigrade.

Versus lead-acid batteries

The company additionally claims that the technology helps reduce the cost of ownership over the battery life by 80 per cent based on the application it is used for. Leveraging the existing technologies from mature industry supply chains, it is, in turn, claimed to allow rapid scaling up through the existing lead-battery infrastructure. The patented silicon wafer plates are claimed to provide performance advantages like 2x depth and discharge rate. The Silicon wafers are known to be used as current collectors and inturn replace the lead grids used in traditional lead-acid monoblocs. The reduced lead helps achieve a 75 per cent lower levelised cost of electricity compared to traditional batteries. An added USP is the elimination of non-uniform current density distribution across the electrodes. This in effect helps reduce or eliminate traditional failure mechanisms such as sulfation and stratification.

The company additionally claims that the technology helps reduce the cost of ownership over the battery life by 80 per cent based on the application it is used for. Leveraging the existing technologies from mature industry supply chains, it is, in turn, claimed to allow rapid scaling up through the existing lead-battery infrastructure. The patented silicon wafer plates are claimed to provide performance advantages like 2x depth and discharge rate. The Silicon wafers are known to be used as current collectors and inturn replace the lead grids used in traditional lead-acid monoblocs. The reduced lead helps achieve a 75 per cent lower levelised cost of electricity compared to traditional batteries. An added USP is the elimination of non-uniform current density distribution across the electrodes. This in effect helps reduce or eliminate traditional failure mechanisms such as sulfation and stratification.

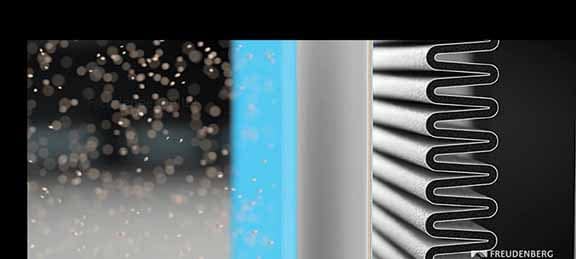

Performance improvements over traditional lead batteries are attained by modifying the existing architectures contrary to electrochemical changes. This is said to allow battery manufacturers the advantage of retaining proprietary advantages across paste formulation, market positions and the distribution channels. It also eliminates the introduction of any poisonous materials or elements into the existing lead recycling streams. The heightened compatibility with lead recycling infrastructures is complemented by the energy savings pertaining to recycling courtesy lower lead concentrations. The method of harnessing the semi-conductive properties of silicon wafers for battery applications is proprietary. Collaborating with a 600GWh-scale global manufacturing base and a near-100 per cent recycling infrastructure, Gridtential and its licensing partners are planning beta and then commercial production of the Silicon Joule enabled batteries across the next two years. Gridtential Inc., won the Battery Council International’s Sally Breidegam Miksiewicz Innovation Award for its proprietary Silicon JouleTM. ACI

Leave a Reply