Hyderabad-based, paint booth manufacturer Dynasole Industries, has recently bagged an order to supply a complete paint shop to upcoming bus maker Deccan Auto. Says AM Rao, MD Dynasole Industries, ‘The commissioning of the project, valued at around Rs. 2.5 crore will be completed by the first week of August. The paint shop, is set to match Deccan Auto’s annual capacity of 3,000 buses.’ The paint shop will provide end-to-end paint solutions, starting from the pre-treatment stage and culminating in the final surface finishing treatment.

Hyderabad-based, paint booth manufacturer Dynasole Industries, has recently bagged an order to supply a complete paint shop to upcoming bus maker Deccan Auto. Says AM Rao, MD Dynasole Industries, ‘The commissioning of the project, valued at around Rs. 2.5 crore will be completed by the first week of August. The paint shop, is set to match Deccan Auto’s annual capacity of 3,000 buses.’ The paint shop will provide end-to-end paint solutions, starting from the pre-treatment stage and culminating in the final surface finishing treatment.

The Deccan Auto project takes Dynasole beyond the familiar. For over two decades now, paint booths have been the company’s forte. Through the course of its journey in the automotive industry, the company has also put out spray booths, combi-booths (a paint booth, with an attached drying oven), paint booth-cum-baking chambers and paint booths suitable for water-borne paints. In FY-13 the company produced 130 paint booths, of which 10 percent were applicated with the commercial vehicle segment. This fiscal, both, deliveries of the booths and the exposure to the CV segment are slated to grow. Almost 25 percent of the 250 paint booths that are likely to be commissioned before April 2014 are to be supplied to customers like Prakash Coach Builders, KMF Coach Builders, SRM Autotech and DRD Trucks.

Having said that, Dynasole is not exactly alien to OEMs. In the past, it has supplied paint booths to Daimler India Commercial Vehicles (DICV), Tata Motors and Ashok Leyland among other customers. Dynasole also caters to passenger car makers like Mercedes Benz India, Volkswagen and Maruti Suzuki. Currently, the company manufactures paint booths at its Hyderabad facility. The plant’s annual capacity to manufacture 75 booths on a single shift basis, will struggle to keep pace with the company’s buoyant order book for this year. Therefore, Dynasole has decided to set up a two-acre, greenfield facility, adjacent to the existing plant. ‘We are constructing an enclosed manufacturing space, spread across 20,000 sq. ft. which will feature enhanced levels of automation when it comes to material movement,’ says Rao.

The new plant will have a capacity to manufacture 350 paint booths annually on a single shift basis. The ramp-up will be gradual. Dynasole will continue to manufacture paint booths at its existing facility for another year. Once the new plant operates to its full capacity, the existing factory will make sub-assemblies and become a feeder plant for the new facility, adds Rao.

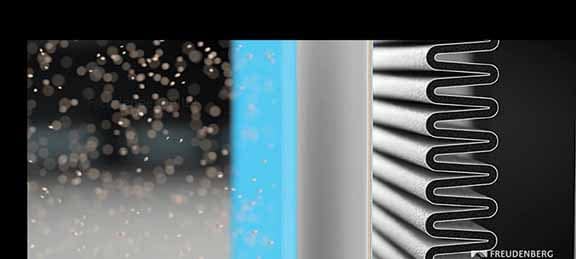

The new plant, is just one among many changes that Dynasole is making this year. It also plans to increase the quantum of components that it outsources. The aim is to free up resources, which can be channelised into product development activities. ‘Its a strategic shift for us. At one time, over 95 percent of our components were produced in-house. That tally has since declined to 65 percent. In time, we plan to boost outsourcing levels to 50 percent,’ informs Rao. To this end, the company has developed eight dedicated vendors, who will gradually become module suppliers. Rao believes that this move will enable the company to enhance productivity substantially, and help it meet rapidly rising demand. The company claims to have manufactured and installed over 700 paint booths thus far. Its base model, refinish paint booths are competitively priced, starting from Rs. 4 lakh and going up to Rs. 20 lakh. The paint booths can be customised easily since they feature a modular construction. The colour-coated steel sheets can be readily dismantled and reassembled after paint operations are concluded. Not limiting itself to the domestic market, Dynasole has been been exploring overseas markets since 2002. It has already exported paint booths, to a few countries in the Middle East, Africa and Sri Lanka. But production constraints held back significant growth on this front. A revitalised production set- up has reignited the interest in the overseas market. ‘We have received enquiries from trading companies, based out of the European Union. In six months, once the new plant is operational, we will apply for the mandatory CE certification required to sell products in Europe,’ says Rao. The foray may take a while to materialise, but the company is ready with its products. The European commercial vehicle aftermarket uses environmentally-friendly, water-based paints. Dynasole has considerable expertise when it comes to providing solutions in this arena. ‘We extended our expertise in providing paint booths that facilitate waterbased paint jobs for the passenger car industry into the realm of commercial vehicles too,’ said Rao. What makes the company doubly prepared is the fact that it has designed paint booths that are tailored to perform optimally in cooler temperatures.

Story and Photography: T Murrali

Leave a Reply