Text: Anusha B

Rajsriya Automotive Industries a Chennai-based tier 1 supplier of sheet metal pressed parts gets into new avenues. The company steps its feet in all sectors like two-wheelers, passenger cars and commercial vehicles. The company’s Daimler India Commercial Vehicles (DICV) business is booming well with their Hosur factory manufacturing 54 parts and in a month’s time 10 more parts will be added in the list. These parts comprise of both domestic and export market. The export market is slowly getting picked up with 1 part now being waved go ahead. It is also hoping that 2 more parts will be exported to Japan and the numbers of the same will soon be seductive. The component maker is also eyeing more business from the two-wheeler makers like Yamaha and Honda.

Speaking to Auto Components India P S Govindachari, Managing Director, Rajsriya Automotive Industries remarked that “In the last couple of years our commercial vehicle components were doing good and giving us huge chunk of business. But due to several reasons the profit margins came down. To offset it and to complement our other business we got centre stand business from TVS Motor Company for their scooters like Jupiter and Wego. This is lending hands to perpetuate our turnover without any hiccups. TVS also brands their pillion handle holder and side stand to ensure quality buy in those parts too through their dealer network and this business also underpins our turnover unhindered.”

The company is manufacturing 2500 centre stands at the moment and is expecting to increase the business to 3000 stands very soon. For Jupiter and Wego a new technology in centre stand called E-Z is introduced. In this if the centre stand lever is pushed the patented E-Z centre stand automatically sits at the centre.

The company bags new business as auto market recuperates now from the fall. The company is in talk with Yamaha Motorcycles and Scooters India (YMSI) for their fan assembly’s powder coating operations. The company will prove its quality with the new orders bagged and slowly will grab the entire product manufacturing witnessing their quality and dedication, highlighted Govindachari. The company is also in dialogue with Bosch for the manufacturing of yoke and coil assembly. The company bagged order from TVS for their exhaust system manufacturing. In addition to that new avenues opened for the company within TVS for the manufacturing of centre stand and accessories mentioned elsewhere in the story.

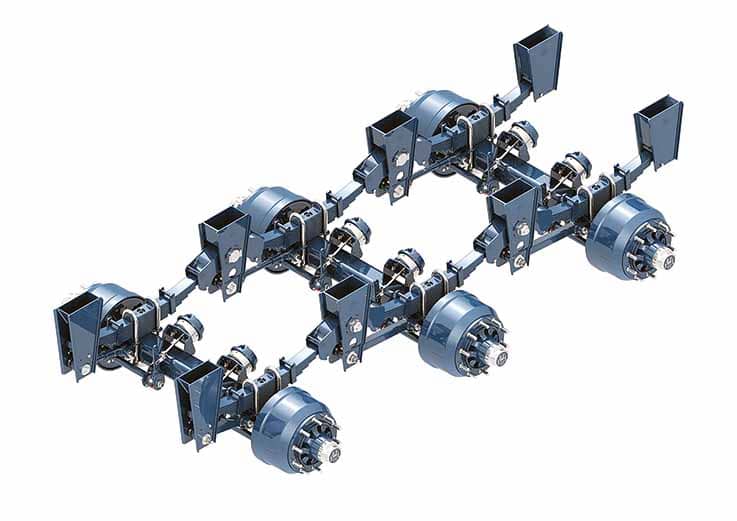

Majority of Rajsriya’s exports comprises chassis parts and the company could finger out a few in transmission. The company is supplying their manufactured parts to Japan for a truck maker. Rajsriya is also catering to the Japanese truck makers another product for a mining variant. All the 64 parts manufactured in their Hosur facility are analogous with the above mentioned vehicles. The company manufactures parts for 4500 trucks per month for domestic market. The numbers of mining trucks is not phenomenal now but it would be around 1000-1500 this financial year and the same will get increased to 3000, 3 years down the line, informs the MD. Within 5 years our mission to manufacture parts for 5000 mining trucks for both domestic and export market will be achieved.

Discussing about the thickness and weight of the parts Govindachari asserted that, “Thickness of the part would be around 10mm and the mass would be measuring about 40-50kg. We get the concept drawing and we do the tool design and in turn it will be approved by the Japanese management and manufacturing process will be initiated in our Hosur facility. To highlight, last year we have made more than 1000 tools. We are at the final stage of negotiation with Ashok Leyland and few drawings are shared with us for chassis part manufacturing. Daimler business for us is on the go and manufacturing operations are going on for their CV segments in Hosur facility. We would like to complete that first and on successful completion we will slowly start processing the orders of Ashok Leyland. The parts manufactured in Hosur will be transferred to Sriperumbudur plant in Chennai and the value additions like welding and machining for some parts are carried on in the Chennai plant,” averred Govindachari. The company is the tier 1 supplier for Daimler and will be ranked the same for Ashok Leyland too.

For a Bangalore based company the company is planning to supply steering assembly products. By means of this initiative the company races in new direction. The company caters them with semi steering system with major sub assemblies getting manufactured here. These get exported to Suzuki Japan. DICV export will be taken care by the company now with the help of Daimler India and eventually will be taken care independently. “With Daimler we have immense learning. Tough tasks and development targets will be assigned to us. They manufacture vehicles to see how the evolving concepts working on with the sample parts. Very stringent delivery targets have also been encountered by us. We always ensure development goes hand in hand with engineering. With effective development in place but the shopfloor does not fit the development standards then the entire process will become futile. As we do both hand in hand we are able to sustain the needs,” Govindachari indicated.

About 80% of the products manufactured by the company goes to TVS Motor Company. For the 2-wheeler maker, it makes several parts including mudguard, steering column parts, muffler, heavy duty carrier etc. In addition, the company also caters to the requirements of Delphi-TVS, TI Cycles, Tafe, Mando, Takata, Brakes India, Lucas-TVS and Rane NSK. It also supplies starter motor assembly to a leading Tier-1 company. The company also exports to Germany and US, to few customers like GE, Saginaw, Bell & Howell etc. Besides, it also exports to Suzuki in Japan.

The exhaust system materials are duly evaluated to abide the emission norms. For environmental reasons the company always contemplate alternate material possibilities. “Aluminium replaces steel but when it comes to high temperatures of over 700 degrees centigrade aluminium could not withstand. We do have grades of aluminium which withstands high temperature but the cost will be highly challenging. We are working on this in various angles and will come up with a strategy,” pointed Govindachari. With all the highlighted projects enter the operational phase, the company expects a turnover of Rs 400 crore and with effective measures in place, soon the turnover will scale high to Rs 500 crore, concluded Govindachari. ACI

Leave a Reply