Text & Photos: Bhargav TS

The newly inaugurated plant in Sanand will help Gold Seal-SaarGummi spread its wings and tap new orders from new customers.

Gold Seal-SaarGummi India, a joint venture between Mumbai-based Gold Seal Engineering Products and Colt-SaarGummi of Germany has bagged the next generation Ford Figo order, which is slated to be launched from the OEs new manufacturing facility in Sanand, Gujarat. To support the OE, the JV company has inaugurated its new manufacturing facility at Jakhwada, near Ahmedabad. Gold Seal-SaarGummi India, which currently supplies various sealing systems for the EcoSport SUV at Ford India’s Chennai plant, will now supply trunk tailgate seals and inner door seals for the new hatchback.

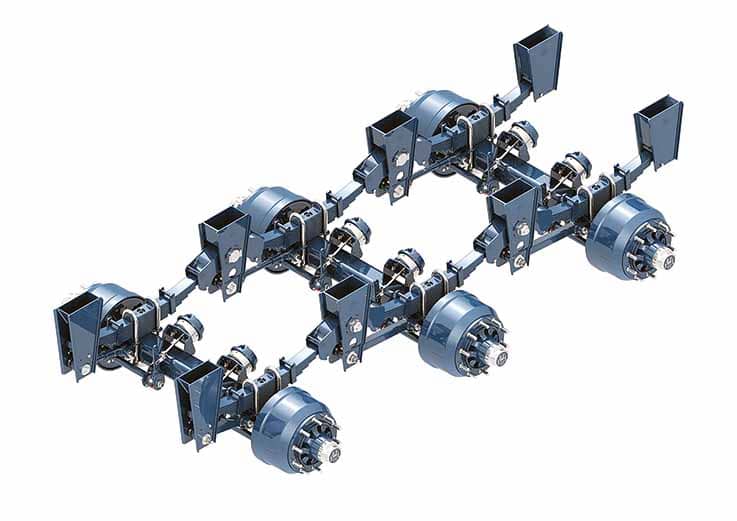

The company currently supplies 26.5 metres of sealings for each Ford EcoSport that comprises 9 profiles including 4 door seals, 4 body seals and 1 back door seal. For the upcoming next generation Figo it will supply 7 profiles, to be manufactured at the new facility. The new plant of Gold Seal-SaarGummi was built at an investment of Rs 51 crore and has commenced operations with one co-extruder line. The second co-extruder line will be set up in mid-April with the third coming up in July this year. Totally, with 5 extruder lines, the output from this plant will total 20,000,000m/year in the next 3 years, says Urvaksh C Aga, CEO, Gold Seal-SaarGummi India. He further said, “Our new plant is strategically

located in the new industrial belt coming up in Sanand, which is poised to be the biggest automotive cluster in Asia-Pacific, surpassing the existing industrial corridors in India. With this new plant we will continue to lead innovation forward for the future and will continue to add customers in this region. We are also speaking to new customers like Suzuki, Honda and a few other companies that are setting up their manufacturing unit here. For Ford’s new Figo we will be supplying 7 different profiles that include body seals, door seals and back door seal.”

Asked about the importance of this new JV facility, Michael Lorig, CEO, CQLT SaarGummi Technologies, said, “This plant is very important for us, since the automotive industry is changing very much, especially in the volume segment. For instance, if you look at our big customer Ford, they have their B platform for which we were supplying sealings. Now, the next product coming in this platform is the B562, which is produced in Sanand, Gujarat. If you look at the global picture, this car was developed and manufactured in Brazil, and also locally built in China and India. Therefore, this is a global car and to satisfy our customers we need to have a plant like this.”

“Frugal engineering had to be used to make sure that there was no compromise on quality for delivering world class technologies to deliver

world class products,” said Darius C Aga, Director, Gold Seal-SaarGummi India. Darius added that the 2 extrusion lines that are currently in

place have been developed with the help of SaarGummi’s innovation with each line having quadruple extrusion capability. “Apart from that we have also installed our mixing unit at the plant with an installed capacity of 25 tonnes per day,” said Aga.

The company has also revealed that it will establish a technical and design centre at the new facility within 3 months. Currently, it undertakes chambers that are currently available in the Daman and Mumbai facility. The entry of Gold Seal’s JV partners was motivated by Ford which insists on top-notch quality for the products it sources. After the plant inauguration, Ford India’s Purchase Director, Madhavan said, “We have our set of preferred supplier partners and we have requested them to setup a shopfloor in this region and all of them agreed to setup a base here. Currently, we have 100 suppliers in Chennai, out of which 17 have setup their manufacturing facility near to our facility in Sanand. Seals are very sensitive to transportation and if you put them in a particular shape for 72 hours, it will deform. Therefore, we requested Gold Seal SaarGummi to have a shopfloor near to our plant. This facility of Gold Seal is state-of-the art right from the raw material pickup station to automatic compounding. We are really satisfied with the work they have done so far and look forward to working with them in the coming years.”

The existing facility in Daman is basically an older plant and this new facility is very impressive with the latest machineries, says Swapnil Walimbe, Deputy General Manager, Strategic Sourcing, Mahindra & Mahindra. “There are lots of technology innovations happening and those

technologies are not coming that much faster to India. So with the help of SaarGummi I hope we will get access to the latest sealing technologies right here, and the facility of Gold Seal will support us by manufacturing those seals in India,” adds Walimbe.

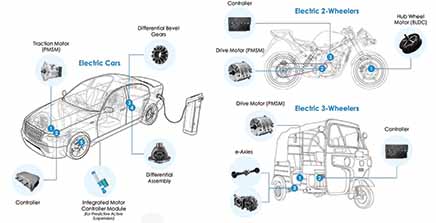

Bajaj Auto’s Component Development Manager, Tryambak D Bharsawade, said, “We are associating with Gold Seal since 2000 and have so far

developed many products for our three-wheelers. According to me, Gold Seal-SaarGummi is our reliable vendor and technology wise they are much ahead of the competitors.”

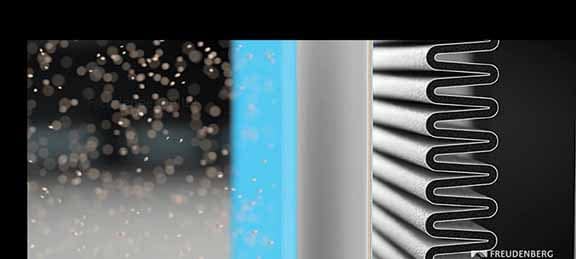

The new plant is capable of manufacturing new technologies like Slip Coating, online air vent hole, online mastic application and complete online cutting with the help of slice moulding. In one line the company can produce sealings at the rate of 12m/min and according to the geometry it can produce more than 800 profiles. Gold Seal’s other clients include VW India (Chakan), Mahindra & Mahindra (for the Bolero platform, and tractors), Nissan Motor India, Force Motors, GM India and a host of others.

Gold Seal was set up way back in 1958 to manufacture and supply rubber door seals and window channels for OEM fitment on the first Indian cars from Hindustan Motors in Kolkata and Fiat-Premier in Mumbai. The company still remains one of the three leading organisations in the field of EPDM rubber weather strips for the latest generation cars. Ford was instrumental in bringing both SaarGummi, the world leader in rubber weather strips, and Avon, the global leader in radiator coolant hose, to India to form a JV with the Gold Seal Group for transfer of latest

technology, manufacturing products of international design and quality for the first time in India. ACI

Leave a Reply