The last couple of years have brought one commonality to all in the auto industry – the need to bring down the cost of manufacturing as much as possible. While some have worked on streamlining the entire process from sourcing to delivery, many have pinpointed specific operations that need re-working. MSC Software, one of the oldest solution providers in automotive

simulation, believes taking to simulation is one such way to reduce the overall cost of production. In fact, according to MSC, it was the cost pressure that made many companies take to simulation in the first place.

The California based company said that simulation can help decrease cost by reducing the number of prototypes that are required during the testing phase. “Our vision is to stimulate the real behaviour of the car so that you don’t have to keep making different

The California based company said that simulation can help decrease cost by reducing the number of prototypes that are required during the testing phase. “Our vision is to stimulate the real behaviour of the car so that you don’t have to keep making different

prototypes,” said Sridhar Dharmarajan – Senior Director and Country Manager, MSC Software. “Our main task is to reduce the number of prototypes that the automakers have to build for testing.” Simulation basically took birth in the aerospace industry where it was too expensive to build prototypes. He informed that there was a time when nearly 50 pro totypes were created for testing of the vehicle which proved expensive for the companies. Now, in many organisations, the number of prototypes used has reduced by nearly 50 – 60%. While simulation has drastically reduced the number of prototypes that are being used during

production, Dharmarajan is of the view that they can never be eliminated completely. “The products are getting more and more complex these days. So while you are able to eliminate some tests, you may have to test for some of the new complexities. So we

are always playing a catch up game to the testing world,” he said.

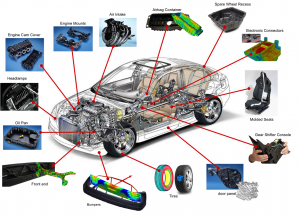

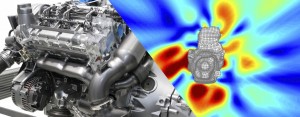

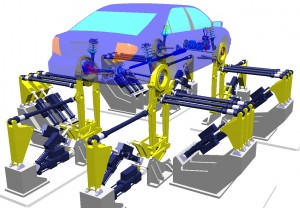

There are four main domains in which the vehicle is simulated. One is the durability domain wherein strength of the vehicle and its life is tested. Other is the NVH domain that is noise, vibration and harshness. Third is the crash domain that is used to test vehicle safety. This is to simulate how a vehicle will withstand a crash; will the airbags deploy and at what speed? Simulation includes frontal impact, side impact and rear impact. The next domain is the vehicle dynamics which simulates ride and handling of the vehicle. There is also simulation for fluid dynamics, which is how the vehicle will behave with a sloshing tank.

There are four main domains in which the vehicle is simulated. One is the durability domain wherein strength of the vehicle and its life is tested. Other is the NVH domain that is noise, vibration and harshness. Third is the crash domain that is used to test vehicle safety. This is to simulate how a vehicle will withstand a crash; will the airbags deploy and at what speed? Simulation includes frontal impact, side impact and rear impact. The next domain is the vehicle dynamics which simulates ride and handling of the vehicle. There is also simulation for fluid dynamics, which is how the vehicle will behave with a sloshing tank.

One of the main areas where simulation helps bring cost down is during testing for a crash or mine blast. This test completely destroys the prototype which proves to be extremely costly. That is where simulation comes in handy for reducing cost.

One of the main areas where simulation helps bring cost down is during testing for a crash or mine blast. This test completely destroys the prototype which proves to be extremely costly. That is where simulation comes in handy for reducing cost.

MSC provides solutions for each of these domains. Some of the software that MSC has in its portfolio are MSC Nastran, Dytran, MSC Fatigue, Sinda, Adams, Actran and SimXpert. Dharmarajan said that the confidence of companies in simulation has gone

up manifold. The success rate is very high, over 95%. This has led to even the component makers jumping onto the simulation bandwagon.

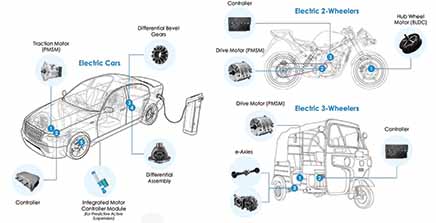

MSC not only supplies solutions to OEMs but also to Tier-1 and Tier-2 component suppliers. Simulation solutions are provided for component level, sub-system level and system level. “Sometimes individual components could be safe but when they are

connected, the sub system may fail. So simulation at all the levels is important,” explained Dharmarajan. One of the main reasons that many of the smaller companies are wary of using simulation is the initial investment that goes into adopting a technology.

To tackle this mindset, MSC is providing very specific packages for the Small and Medium Enterprise (SME) segment so that they can afford the solutions at a certain price point. The company has trimmed out certain features that SMEs may not require, thus

reducing the price of the software. According to MSC, with competition increasing, simulation has become a necessity even for SMEs. As of now, SMEs don’t just compete with Indian companies but also with their global counterparts. Even the customers who

they have to sell to are now global. The OEMs today are asking component manufacturers to design their products, unlike the past when the design was given to them by OEMs. This has led to a change in relationship of the company with the SMEs. While earlier

MSC had to take the solutions to the SMEs, now they are coming to MSC asking for a solution.

Leave a Reply