Tsuyo Manufacturing’s LOI with Karnataka marks a strategic push to scale India’s EV powertrain capabilities through advanced production and integrated testing, writes Niharika singh

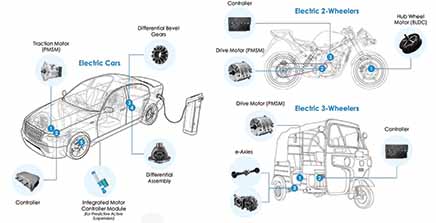

At the Bengaluru Tech Summit 2025, mobility startup Tsuyo Manufacturing entered a significant new phase with the signing of a landmark Letter of Intent (LoI) with the Government of Karnataka. The LoI is aimed at establishing a developed electric vehicle powertrain manufacturing complex and an expansive testing track dedicated to commercial electric mobility. The agreement was formalised in the presence of Karnataka’s senior leadership, including Minister Priyank Kharge, government officials, Tsuyo directors, among other delegates, reflecting the state’s strategic emphasis on strengthening advanced manufacturing. The proposed facility, to be developed in Dharwad, is intended to evolve into a comprehensive hub capable of designing and producing multiple categories of powertrain systems, including interior Permanent Magnet Synchronous Motors (PMSM), induction motors, switched reluctance motors, synchronous reluctance motors, axial flux motors, e-drives, e-axles, automatic transmissions, and multi-in-one integrated systems. These are capable of powering a wide range of heavy-duty electric vehicles. With a dedicated testing track built into its blueprint, the facility is expected to enable faster development cycles and rigorous field validation tailored specifically to Indian operating environments.

New Powertrain Facility

The details of the proposed project reveal a facility conceived as an integrated engineering-to-validation ecosystem. Tsuyo aims to build manufacturing capabilities across à wide power band, from 0.5 kW to 250 kW, with scalability up to 600 kW through its technology partnerships with CETL and LvKON.This broad operational range positions the facility to serve electric buses, freight trucks, mining vehicles, industrial hauliers and other platforms that demand high torque, sustained thermal stability and robust long-duration performance. The inclusion of a testing track marks a crucial aspect of the plan, addressing a longstanding gap in India’s heavy-duty EV development cycle. Commercial-grade electric powertrains require extensive endurance testing across different terrains, loads and thermal conditions, something that only a handful of facilities currently offer at scale. By embedding testing infrastructure directly into its manufacturing ecosystem, Tsuyo intends to reduce development lead times while enabling real-world tuning that reflects the country’s climatic and operational complexities.

Priyank kharge, Minister of Rural Development and Panchayat Raj of Karnataka

Karnataka Strenthens EV Strategy

For the Government of Karnataka, the LOI aligns with its broader strategy to reinforce advanced manufacturing and decentralised industrial growth under its ‘Local Economy Accelerator Programme’. Minister Priyank Kharge emphasised that Tsuyo’s decision to expand in Dharwad validated the state’s efforts to attract innovation-driven industries and build a balanced economic landscape beyond metropolitan hubs. The project is expected to generate high-quality employment and stimulate regional industrial corridors, helping North Karnataka consolidate its emerging status as a mobility and engineering cluster. Karnataka has long positioned itself as a technology-forward state, and the establishment of a heavy-duty EV powertrain facility complements its drive to strengthen local supply chains in sunrise sectors. The government’s policy environment, particularly its emphasis on clean mobility, electronics manufacturing and research-led industries, has created favourable conditions for companies seeking to scale complex engineering operations within India.

India Eyes Domestic Powertrains

The significance of the LOl extends beyond any single company. India’s heavy-duty EV segment has expanded more slowly than its two-wheeler or three-wheeler categories, largely due to higher performance requirements, complex component supply chains, and the scarcity of domestic high-power powertrain manufacturers. Despite growing fleet electrification in buses, mining vehicles and logistics operations, India remains heavily reliant on imports for motors, high-capacity drives, e-axles and integrated heavy-duty powertrain systems. These imported systems often come with cost premiums, long procurement cycles and limited customisation for Indian conditions. An indigenous manufacturing ecosystem capable of producing high-power powertrains domestically could reshape the sector’s economics. Tsuyo’s Dharwad facility, positioned to supply components across multiple commercial EV segments, aims to contribute to addressing this localisation gap and potentially reduce the sector’s dependency on foreign technologies.

From Motors To Complex Sub-System

Tsuyo Manufacturing’s development as a company reflects the broader evolution of India’s EV component ecosystem. Established with the intention of designing and manufacturing electric mobility components within the country, Tsuyo began by focusing on electric motors and drives before expanding into more complex sub-systems, including converters, instrumentation panels, gearboxes, axles and integrated e-axle assemblies. Its engineering philosophy has emphasised multi-topology capability, allowing the company to work across various motor technologies rather than relying on a single architecture. This adaptability has allowed Tsuyo to cater to diverse applications, from light mobility to industrial-grade machines. Over time, collaborations with CETL and LvKON have enabled the company to enter higher-capacity powertrain segments, positioning it as an emerging domestic supplier for heavy-duty applications that traditionally required imported engineering solutions. Tsuyo’s journey reflects the shift from component-level manufacturing to system-level integration, a trend increasingly characterising the global EV powertrain sector.

Heavy EV Sector Shifts

India’s gradual move towards electrifying commercial mobility is shaped by policy mandates, fleet economics and the recognition that heavy-duty transport contributes disproportionately to emissions. State transport undertakings are leasing electric buses in growing volumes, metropolitan logistics operators are exploring electric freight vehicles, and mining companies are evaluating electric haulage for cost and sustainability reasons. Despite this momentum, the industry faces a shortage of domestically available,high-reliability powertrains suitable for continuous, heavy-load duty cycles. Commercial EV operators place a premium on uptime, predictable maintenance cycles and thermal stability-areas where imported systems may not always align with India’s temperature extremes, dust exposure and steep gradients. A dedicated powertrain manufacturing hub in India could therefore enable commercial EV adoption to progress at a faster rate, provided the systems deliver the performance and longevity expected by fleet operators.

Testing Infrastructure Gains Importance

One of the most significant features of Tsuyo’s proposed development is the inclusion of an extensive testing track designed specifically for validating heavy-duty EVs. While India’s automotive sector has extensive experience in testing internal combustion engine vehicles, electric powertrains, especially in commercial applications, require different validation protocols. Key aspects of EV testing include continuous torque testing, thermal cycle stability, load endurance, regenerative braking optimisation, and real-world terrain simulation.

The absence of widespread, large-scale testing facilities has often hindered the localisation of EV technologies in India. By integrating the testing track with its production facility, Tsuyo aims to create rapid feedback loops between design, manufacturing, and real-world validation. This infrastructure could help shorten product development timelines, refine performance parameters specific to Indian routes, and potentially encourage other manufacturers to collaborate on testing programs.

Dharbad Emerges As An EV And Engineering Hub

Dharwad’s rise as an EV and engineering hub is a reflection of Karnataka’s broader industrial redistribution strategy. The district has attracted significant manufacturing investments in recent years due to its growing industrial corridors, improving infrastructure and availability of a technically skilled workforce. Its proximity to established automotive regions, combined with favourable connectivity, has made it a logical location for companies seeking to scale production without the congestion and cost pressures of larger metropolitan centres. Tsuyo’s planned facility aligns with the state’s vision of expanding industrial capacities beyond Bengaluru and creating balanced economic growth across regions. Such decentralised industrial development also supports resilience in supply chains, an increasingly crucial factor as global manufacturing reconfigures in response to geopolitical and logistical challenges.

Powertrain Capabilities Deepen Locally

Tsuyo’s expansion is part of a broader movement within India’s electric vehicle (EV) supply chain aimed at strengthening domestic capabilities in advanced technologies. While vehicle assembly has grown rapidly, the localisation of high-value components such as motors, drives, and power electronics has not kept pace. The new facility in Dharwad is strategically positioned to address this gap by developing a domestic ecosystem capable of supplying high-performance powertrains designed for Indian conditions.

The company’s modular approach to powertrain architecture, supported by its engineering partners, could allow for the production of platforms suitable for various categories of heavy-duty EVs. If successful, this facility may not only reduce dependence on imports but also establish India as a competitive exporter of commercial EV powertrains in the long term.

EEV Ecosystem Poised for Expansion

As India works to accelerate its transition to electric mobility, particularly in commercial sectors, the establishment of a dedicated domestic powertrain ecosystem may play a pivotal role. Fleet adoption decisions often hinge on system reliability, Total Cost of Ownership (TCO) and after-sales support-areas where localised engineering and manufacturing provide clear advantages. Tsuyo’s integrated design, production and testing model has the potential to influence how quickly electric buses, trucks and industrial vehicles can scale in India. By aligning technical development with real-world validation and state-level policy support, the project could serve as an example of how public and private stakeholders can collaborate to strengthen the foundation of India’s clean mobility journey.

Strategic Move

The LOI between Tsuyo Manufacturing and the Government of Karnataka marks both a corporate milestone and an indicator of India’s shifting industrial priorities. As the country seeks to strengthen its position as an EV manufacturing hub, investments in high-technology, high-capacity powertrain systems become essential. The Dharwad project, with its combination of manufacturing capabilities and testing infrastructure, represents an important step toward building a self-reliant heavy-duty EV ecosystem. While the facility’s long-term impact will depend on execution, market response and technological outcomes, its intent aligns with India’s ambition to create a robust, innovation-led and globally competitive mobility sector.

Leave a Reply