Story: T Murrali

Component manufacturers in India have qualitatively evolved over a period of time due to a range of factors, the prime one being the drive from OEMs. When vehicle manufacturers raised the bar in terms of quality, cost and delivery, vendors had to rise to the occasion and match expectations; The impetus came with opening up of the economy and Deming Prize as they paved the way for MNCs to set up shop in India, looking at sourcing of components. Along with this, it also gave them the opportunity to look beyond boundaries for business.

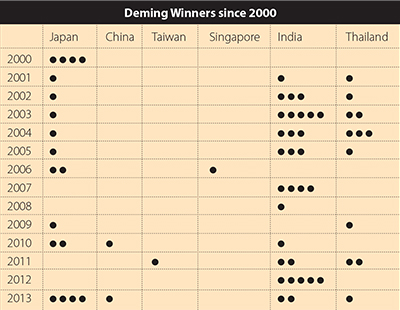

The quality movement evolved in India during the mid 1980s with the Confederation of Indian Industry (CII) propagating the need for improving quality and, consequently, beginning the cluster approach. Also in 1986 when the Japanese Union of Scientists and Engineers (JUSE) allowed foreign countries to apply for the Deming Prize (DP), not many Indian companies took advantage of it. The DP was constituted based on Dr W E Deming whose contribution on statistical quality control helped Japan build up its foundations after World War II, besides recognition as a quality destination in the world.

Katsutoshi Ayano

Katsutoshi Ayano

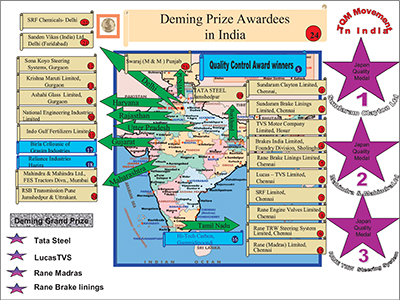

After opening up of the economy, very few industrialists including Venu Srinivasan from the TVS family felt the need to improve quality of business to cope with international competition. Srinivasan was one among the very few in India to propagate the quality movement following Total Quality Management (TQM). With the result two of his companies won the DP. While the brakes division of Sundaram Clayton (now Wabco India) was the first Indian company to get the DP in 1998, TVS Motor Company won the same in 2002, becoming the first two-wheeler manufacturer in the world to get this coveted award; few companies followed later. While there are several globally recognised awards, why is the Deming so popular in India?

Understanding Deming

There are three excellent models of quality management in the world, namely, the DP in Japan, the Malcolm Baldrige award in the US, and the EOQ award in the EU. According to Katsutoshi Ayano, Professor – Department of Business Administration – School of Political Science and Economics, Tokai University, Japan and Director -The Japanese Society for Quality Control – Malcolm Baldrige and European EOQ awards are given to the companies in each region who are selected based on competition among the applicants. DP is open to the global community and awarded to applicants on merit; it is not an award to be won by competing with other companies.

DP is an annual award presented to an organisation that has implemented TQM, which is a set of systemic activities carried out by the entire organisation to efficiently achieve organisational objectives; to provide products and services with a level of quality that satisfy customers, at the appropriate time and price. The examination does not require applicants to conform to a quality management model provided by the DP Committee (DPC). Not only the results achieved and processes used but also expected effectiveness in future are subjects for the examination.

Interestingly, India continues to be the second largest in terms of the number of recipients in the world, next only to Japan. Thailand stands third; however, the country has established the Kano Quality award, which is its own version of the DP based on the awards scheme. Dr Sarita Nagpal, Principal Advisor, CII, explains, “After Sundaram Clayton’s achievement, the movement picked up rapidly as Professor Tsuda and other Japanese experts began educating companies on TQM.” Recalling Tsuda, who always insisted that, “we should practice TQM only if it benefits our customers, employees and impacts business,” she said the professor discouraged companies to go for awards if it did not make business sense. She continues, “CII Exim Business Excellence Award has more responses than the DP. Close to 200 companies in India have gone through CII’s TPM club for TPM (Total Preventive Maintenance); these awards are from the Japan Institute of Plant Maintenance. I think Japan has always been a great proponent of quality and manufacturing, and Indian industry does learn and adopt good practices by challenging such awards.”

According to Dr V Swaminathan, Director, Vsam Associates and advisor to NIQR National President, the cluster programme initiated by Maruti and CII to develop auto component manufacturers under Tsuda was the turning point. With the success of the first cluster, the second one began subsequently, and as the benefits of getting into the TQM movement spread, several other companies turned their attention towards this and got involved in the process.

The benefits for companies that received the DP were immense. Established in 1962 as Sundaram Clayton, a joint venture between TVS and Clayton Devandre to manufacture braking systems, the company was de-merged into WABCO-TVS (India) in 2008 with the global company taking majority ownership the following year. “The Deming Award motivates us to embrace continuous improvement every day. TQM touches all of our processes, products and services through total employee involvement. As a result, we realise increased customer satisfaction, market share, customer loyalty and improved business results,” says P Kanniappan, Whole-time Director, Wabco India. Restructuring its manufacturing cells and introducing TPM and lean manufacturing tools, built up competency and reduced rework, process scrap and machine breakdowns. “The predominantly manufacturing focused organisation transformed into a ‘product development’ one as we started investing more in developing our own products and automobile test track facility way ahead of time.”

Chennai headquartered Rane Group has to its credit four DPs and three Deming Grand Prizes (DGP) formerly known as Japan Quality Medal. Rane Brake Lining Limited (2003), Rane Engine Valve Limited (2005), Rane TRW Steering Systems Limited -Steering Gear Division (2005) and Rane (Madras) Limited (2007) received the DP. Except for Rane Engine Valves, all other companies have received the DGP, which is given to companies that sustain quality levels continuously for more than four years.

Says L Ganesh, Chairman, Rane Group, the journey has immensely benefited the group on several aspects. “The process has transformed the mindset of our employees. Manufacturing operations are always viewed in terms of meeting customer requirements, with continuous improvement and total employee involvement.” Since TQM focuses on the process approach, it ensures consistent results. “The focus has been on improving and transforming the processes for achieving better results in terms of productivity, quality, cost, delivery, safety and morale. The emphasis is on preventive measures; a lot of preventive and detection pokeyokes are implemented. Many of our plants have achieved single digit customer line rejection ppm,” he adds.

For Sona Koyo Steering Systems that won the Deming Award in 2003, the experience transformed the entire organisation. The Managing Director of the company, Sunjay Kapur says the effects were not limited to manufacturing, but extended to product development, human resources development, as well as marketing. “The entire organisation worked in a cohesive manner towards a single shared goal. This energised people and brought out the best in them.”

“Total number of Deming Prize winners is 232 including 43 from overseas.”

Auto electrical major Lucas-TVS won the DP in 2004 and DGP in 2012. The journey helped the company, which saw a serious challenge to its leadership position from MNC competitors, instill customer awareness in all its employees and made them realise that in a highly competitive market the only way to grow business is by satisfying customer needs. The Executive Director of the company Dr Ravichandran says, “The journey has helped us to clarify the roles and responsibilities of employees at various levels and taught us the need to strictly comply with the standard operating procedures to maintain current standards and improve on them. The TQM philosophy with its emphasis on ‘continuous improvement’ has also focused the efforts of all our employees on improving the business processes to achieve higher levels of customer satisfaction.”

“We were previously ‘operating the business’ and now we are ‘managing the business’,” says V Narasimhan of Brakes India, which won the DP in 2003 (for the foundry division). Policy management is now the cornerstone of the business. “We are cascading the vision down the line through objectives and strategies, aligning all activities of the departments and individuals to realise them. We have made a fundamental shift towards systematic analysis, pre-planning and blue printing of operations with focus on habitual improvements with the controls embedded in the system.” Currently the company is working towards satisfying the ‘latent needs’ of the customer, beyond meeting the ‘stated needs’, with the concept of ‘attractive quality.’

RSB Transmissions (I) Limited won the DP in 2013. The company’s Vice Chairman & MD, S K Behera says, the exercises have demarcated the responsibilities of every individual to satisfy not only customers but also every stakeholder including employees and bankers.

New Product Development

The Deming journey has presented recipient companies with huge opportunities in New Product Development (NPD). For Brakes India, NPD time has contracted to 25% of what it was a decade ago. Since emerging regulations and technologies reflect new demands for products and customers, the company is emphasising more on value, quality, safety and green processes. Narasimhan says the concept of ‘Green Products’ with accent on product stewardship and life-cycle management has become the need of the hour. “Developing new materials/ alloys by adopting breakthrough methodology is giving us opportunities in new markets. Collaborating with the customer on NPD to drive the costs down, at the same time improving product features is the approach. Simulation of the sand flow, metal flow and solidification is the key feature of the virtual environment in the technology department.”

Ganesh says the recognition has made the group emphasise more on NPD. “Proactively, the employees concerned engage with the customers and ensure that customers’ stated and latent needs are captured and transformed into new products that satisfy them. The review stages are made robust to ensure products are ‘first time right’ always. Through continuous improvements, the lead time for NPD has come down significantly.”

Lucas-TVS, for instance, is moving towards a simulation based design where as much upfront design and evaluation as possible is carried out in digital form. Rapid prototyping enables visualisation and getting initial customer feedback. “While the mainstream of NPD is devoted to meeting current customer requirements, we have established an Advanced Engineering Section to address the need for breakthrough product development with new technology to meet customer requirements in the future,” says Ravichandran. The company focuses on products that can address concerns like emission, fuel efficiency, sustainability and end-of-life disposal.

Human Resources

TQM practices have significantly improved the work culture in the organisation with people having total clarity on their roles and responsibilities, aligned together in contributing towards company goals. At Lucas-TVS many unique practices are in place like ‘Sunday Voluntary Work Team,’ where 600 workers come on Sundays, work voluntarily for 4 to 5 hours and take many improvement projects on 5 S, safety, quality, quick changeover, TPM, environment, etc. The company that was established in 1961, is currently pursuing programmes to raise skill and morale for a cordial employer – employee relationship and Total Employee Involvement (TEI).

Rane group views competent and skillful human resources as differentiating factors in the competitive environment. “There is a kaizen culture with TEI; voluntary involvement is ensured through suggestions, Quality Control Circles (QCC), Quality Improvement Teams and Cross Functional Teams that take up business related projects. These concepts focus on productivity, quality, cost, delivery, safety and morale. For example, 40% of the projects are related to quality. About 1,000 QCC projects are completed every year and the QCC and suggestion participation percentage is full in most of the locations. Other employee engagement initiatives, and providing challenging assignments, have contributed to a large extent in the retention of key talent.”

The President & CEO, National Engineering Industries, Rohit Saboo, says Deming has helped the company change its culture in terms of TEI. About 40% of the workmen in the company that makes bearings under the NBC brand have understood the system, which was zero earlier. “The departments that were divided by walls previously have been working together, which helped us rise faster. While trying to get the award we worked hard, but there was a lull after that. We realised this within three months and acted swiftly, eventually gaining momentum, which helped us to take up the audit again. This led us to challenge DGP this year,” he said.

For Brakes India it helped to recast its vision of improving the quality of work-life of employees, considered part of an extended family of the company. The management has empowered the employees and instilled concepts of ownership and accountability. Narasimhan says, “We are working to form talent pools with traditional and non-traditional workers to create a flexible, cross-trained workforce. We are investing in long term skill development and working towards competency based management.” In addition, the company has been experiencing a significant change in the buying preference of its customers, “with expectation of dramatic and not incremental cost reduction. Customers expect a new business model from us highlighting infrastructure, value configuration and our offer of a new value proposition. The focus has shifted towards our capabilities rather than positional assets.”

Rane’s experience with customers is in terms of increasing confidence levels and quality assurance systems. Periodic customer satisfaction surveys help the group understand customer problems and take corrective action. Ditto with Lucas-TVS as its customers expect flawless launch, consistent performance in quality, cost, delivery and safety, and partnership with them in NPD and cost reduction programmes. “Of late, we have had the opportunity to expand our customer base to include many demanding global OEMs. Our TQM philosophy has enabled us to execute these challenging projects to customer satisfaction,” avers Ravichandran.

Says Saboo, “As we are not an MNC, we are always perceived as second in the pecking order when it comes to customers’ preference. After getting the award they started looking at us in a better light. Exports as a percentage of turnover have improved from less than 2% before 2010 to about 17% last year. We are extending the TQM methodology to our suppliers to improve the entire value chain. Though there is a long way to go, it has helped us as supplier systems are streamlined now. Currently, about 10% of the vendors supply directly to the shop floor without quality check from our side, from nil earlier.” Sona-Koyo’s exports were negligible prior to 2000. After receiving the award, the company was able to position itself as a quality company even if India was not known for quality products those days. Post 2003, Sona-Koyo’s exports surged, with its entry into the off-highway market in the US. This entry was made easy due to Deming, reiterates Kapur.

Behera says the journey highlights the company’s cultural change of delivery to customers in terms of right quality, time, volume and sequence. “The award educates the customer of this change, to expect only top class products from us. We have started work on the next stage of Deming.”

Profitability

While there are immense benefits in terms of customer satisfaction and confidence, it is profitability that will keep suppliers healthy. Even in the current economic situation Lucas-TVS is able to sustain the gains that it enjoyed so far due to TQM approach. The engagement of people and deployment of goals through the organisation has helped improve overall efficiency and alignment. Narasimhan says, “The profitability has multiplied manifold and we have emerged as an outfit of scale and substance.”

Ganesh reiterates that profitability is largely volume driven in the auto component industry. For that reason, the group suffered in 2013-14. However, “due to TQM practices and other initiatives like reduction in fixed costs and capex, we have managed to be profitable, although much lower compared to previous year due to volume drops,” he adds.

For Sona Koya, profitability was eroding since 1998 due to competition in the automotive industry that set in post liberalisation. However, “this trend was reversed in a strong way, thanks to all-out efforts by members of the company while they were working towards Deming. The profit before tax as a percentage of turnover has improved from 5.4% in FY99 to 8% in FY14,” points out Kapur.

Deming gives several benefits; it makes companies be on their toes always. While it may be a propellant for a successful journey, to some extent it makes a few companies restless, opine some industry experts. Narasimhan states, “the downturn and the consequent slowing of the global economy accompanied by high profile bankruptcies, poor utilisation and job losses elsewhere has totally masked outstanding achievements in improving quality and productivity without increase in price.” Ganesh feels that there are no negatives as such. The expectations from all the stakeholders have increased. Ravichandran quips by saying that, “sometimes employees think by achieving this award, we have achieved global quality standards when this is just a milestone in a long journey.”

Notwithstanding several attributes

to TQM, the number of companies applying for the award is diminishing. Of the total 23 companies in India, 7 companies obtained the next level – DGP. Any company can apply for DGP after about four years of getting the DP. Going by this, in 2009, India had 20 DP recipients. However, only 7 companies have gone to the next level – Sundaram Clayton, Mahindra & Mahindra, Rane TRW Steering Systems, Tata Steel, Lucas-TVS, Rane Madras and Rane Brake Lining. What is the reason for this? “I think maybe this is seasonal. With Tata Steel and Mahindras going in for Deming, I expect to see popularity grow,” says Nagpal.

Ayano says, except for a few companies, owners and top management delegate and leave the promotion of TQM to their subordinates. Their main focus is short-time financial success rather than long term business achievement through customer satisfaction. He further states that the DP committee does not give any failure status to companies; if a company does not reach the required level, it is regarded as pending.

“Total number of the Deming Grand Prize winners is 27 including 7 from India.”

According to Dr A Sanjeeva Rao, Executive Director, Sanjeev Quality Consultants and Director – Quality Circle Forum of India, there are three challenges – quantum of efforts by the management and employees, higher investments and sustenance. He further says that the two vital parameters to apply for the DP – high dedication and passion – are missing now, hence the drop in number of companies getting the award. Similarly with companies who already received the prize but have not gone in for the higher level. As the name indicates, DP is a prize given for a particular year. However, it does not qualify recipients to be addressed as Deming companies throughout, as is being done in India. It is valid for that particular year of assessment, and is to be applied once in five years. The drop is because of lack of passion and dedication.

Swaminathan feels that since TQM is process oriented, besides developing the culture of the organisation, it consumes a lot of time and money. Therefore, the involvement of companies is coming down. It takes about five years to challenge Deming from initial assessment. Also, it costs about Rs 3 crore now, which was limited to Rs 75 lakh in 2001. Further, applicants have to fare well in CSR activities, as part of the criteria. Moreover, some business groups have their own process to identify excellence, so they are not evincing interest in Deming. “Unless it becomes a national movement as it is in Japan, to develop quality, it is not possible to make companies get into this movement despite CII and ACMA taking it. Economic slowdown is the time for getting in to these things as it gives enough time to change,” he adds.

Deming recipient companies may fail in business if they do not continue the practice, says Ayano. It is a recognition proving that the company has improved on performance by applying TQM. Nagpal pitches in stating that companies may go through ups and downs, but the committed ones remain to journey.

The Way Forward

The way forward for Deming recipients is to sustain performance levels and endeavour to raise the bar continuously. “We are contemplating certain initiatives that would help us achieve the same. We are pursuing business excellence through TQM,” says Ganesh. On the other hand Lucas-TVS have set a challenging target under Vision 2017 in which it will ensure efficient execution of actions arising out of the identified effective strategies. “We will also aggressively expand our presence in the export market in the coming years, in addition to developments that are taking place in the local markets,” asserts Ravichandran.

Brakes India’s forward focus comprises of many options including emphasising on data driven decision making, manufacturing and process reforms, and integrated risk management. Besides, the company will simulate to see the unseen and be ready with the response. The main focus will be on green energy, processes and products. Sona Koyo decided to pursue the new management method of breakthroughs. In addition to the control and continuous improvement methods of TQM, the company embraced new paradigms in innovation. Some of the results of these initiatives were creation of new products and acquisition of new markets.

Expert Opinion

Nagpal emphasises that the aim of implementing TQM should always be improvements first, then awards. Many companies worked at TQM for many years and consciously kept raising the bar to challenge the award only when they were satisfied with the results. “Like that, I am sure there could be many reasons for companies who are in the Deming journey, who would be comfortable only if their business goals are met and a culture of continuous improvement sets in,” she adds.

Opines Ayano that challenging the DP is not an issue for Indian companies but they should learn how to employ TQM practices to run the business in a competitive manner to cope with the international market. Rao feels that in order to survive, any organisation should delight its customers and to achieve this objective it has to follow certain self-laid guidelines and sustain them. In the US, for instance, the orientation is on the results part while it is processes that fetch results, in the case of Asian countries. Companies should address abnormalities to sustain the quality movement, eventually keeping the customer satisfaction index high. They can practice TQM as it increases capability of employees, mean time between failure and response, machine availability and teamwork. Ayano, who is also Chief Advisor, Center of TQM, SRM University, points out that a few Toyota group companies decided to enter the India after visiting few Deming companies here. This is because it made them confident that component manufacturers could implement TQM successfully. Deming companies cannot be successful and become demigods if they do not practice the concepts religiously. ACI

-with inputs from J Srikant & Bhargav TS

Leave a Reply