Setco Auto is revolutionising clutch technology with new innovations. Neeraj Singhal talks of expanding global footprint, and embracing a digital-first approach while driving future advancements in clutch technology with Upendra Kasbekar.

Q: What drives Setco’s continued advancements?

A: We have been part of the automotive industry for over 40 years, supplying clutches for commercial vehicles in India and abroad. Events like this provide an excellent platform to showcase our latest developments, interact with key stakeholders, and understand industry trends. It’s a two-way street, we get to present our products while also observing how the market is evolving. The presence of international visitors also helps demonstrate India’s capabilities in mobility solutions on a global scale.

Q: Setco is closely associated with OEMs. Which key partnerships stand out?

A: Tata Motors is our largest customer, contributing over 70 per cent of our revenue across both Original Equipment (OE) and Original Equipment Service (OES) segments. Our clutches are present in nearly all Tata trucks. Additionally, Ashok Leyland accounts for around 15 per cent of our revenue, and we are also exclusive suppliers for certain models. We maintain strong relationships with Mahindra & Mahindra, Volvo Eicher Commercial Vehicles (VECV), and other major truck manufacturers in India.

Q: What are the key products that you supply to these OEMs, and how are their requirements evolving?

A: We primarily supply clutches for Medium and Heavy Commercial Vehicles (MHCVs), covering sizes from 310 mm to 430 mm diameter, catering to trucks ranging from 10-50 tonne. As India’s road infrastructure improves, OEMs are shifting towards higher-tonnage trucks. The demand for 430 mm clutches is growing significantly, and Setco has been a pioneer in manufacturing these in India.

There is also a gradual shift from manual transmissions to Automated Manual Transmissions (AMTs) in commercial vehicles. While AMTs are common in passenger cars, their adoption in trucks has been slow due to cost concerns and the need for a fully integrated driveline. However, this transition is inevitable. Our R&D team is actively working with OEMs to develop AMT clutches, ensuring we are ready when mass adoption begins.

Q: What challenges do you see in the transition towards AMT technology?

A: The commercial vehicle industry is highly cost-sensitive. Indian fleet operators prioritise economic viability over technological advancements. While passenger cars have seen rapid adoption of automatic transmissions, trucks are still largely manual due to the high cost of AMT systems and the need for drivetrain modifications.

However, we anticipate that within the next five to 10 years, AMT adoption in trucks will increase. Our engineering team has been working on AMT-compatible clutch solutions, and we are already involved in trials with OEMs like Tata Motors for self-adjusting clutches and AMT-ready components. Developing these technologies early ensures we remain ahead of the curve when market demand scales up.

Q: Setco has been in the market for decades. How do you balance innovation with market realities?

A: In India, cost is always a major factor. Customers demand both affordable and high-quality solutions, so we need to introduce new technology at a manageable investment level. We closely analyse market trends and invest in R&D accordingly not too aggressively, but with a clear vision of the future.

For instance, when we developed the 430 mm clutch over a decade ago, the market was still evolving. We started with small production volumes 10, then 50, then 100 units before scaling up to thousands today. We apply the same approach to AMT and self-adjusting clutch technology.

Q: Any upcoming product launches in the pipeline?

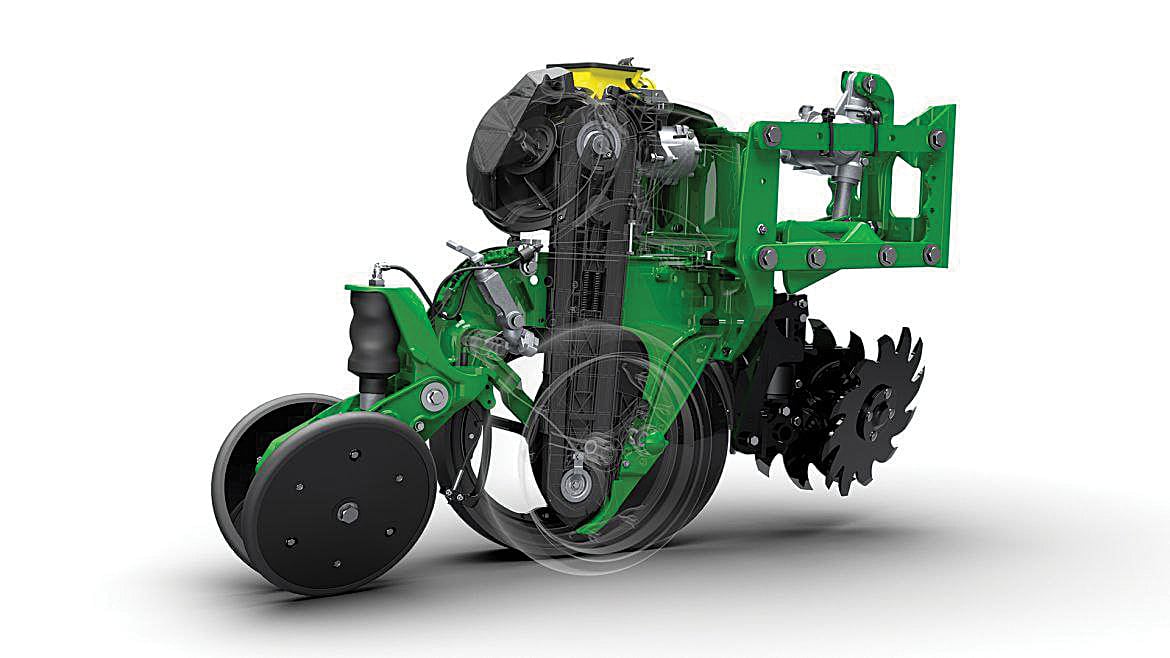

A: While our primary expertise lies in M&HCV clutches, we are now expanding into new segments. We have received Requests for Quotation (RFQs) from tractor manufacturers like CNH Industrial, ITL, and Mahindra Gujarat, and we are developing tractor clutches to cater to this demand.

We are also strengthening our presence in the Light Commercial Vehicle (LCV) segment, targeting models like Tata Yodha, Mahindra Bolero Pik-Up, and other utility vehicles. At the expo, we displayed our 260 mm clutch, and by the next financial year, we will introduce 240 mm and 260 mm clutches. These products have already received design approvals, and we are currently in the sample production phase, with mass production expected to begin soon.

Q: Where are Setco’s manufacturing operations based?

A: Our primary manufacturing facility is located in Vadodara, Gujarat, along the Godhra

Highway. This is a fully integrated plant with the capability to manufacture all components used in our clutches. Additionally, we have an assembly plant in Uttarakhand (Sitarganj), which caters to Tata Motors and Ashok Leyland plants in the region. Components from Vadodara are shipped to Sitarganj, where they are assembled before distribution.

Q: How does Setco ensure its products remain competitive in a rapidly evolving market?

A: We focus on three core areas innovation, quality, and cost-efficiency. We invest heavily in R&D to develop next-generation clutch technologies, ensuring that our products align with evolving OEM requirements. Simultaneously, we optimise manufacturing processes to keep costs competitive while maintaining international quality standards.

With the industry shifting towards higher-capacity trucks, AMT integration, and new mobility solutions, we are positioning Setco as a future-ready partner for India’s leading commercial vehicle manufacturers. Our goal is not just to keep pace with industry changes but to anticipate them and innovate ahead of time.

Q: How will Setco contribute to shaping up the future of commercial vehicle drivelines?

A: The Indian trucking industry is on the brink of transformation, driven by infrastructure growth, regulatory changes, and technology upgrades. As the market leader in commercial vehicle clutches, Setco is committed to providing durable, efficient, and future-proof solutions. Whether it’s scaling up high-tonnage vehicle clutches, innovating for AMTs, or expanding into new segments, we remain focused on delivering excellence and driving the future of mobility in India. ACI

“India’s trucking industry is evolving, and Setco is driving it forward with durable, efficient, and future-ready clutch solutions.”

Leave a Reply