Freudenberg Filtration Technologies India has introduced advanced in-cabin air filtration solutions and services.

Story by: Deepti Thore

We’ve all learnt the importance of breathing in clean air by now. It can’t be stressed enough! With Covid-19 persistent, Original Equipment Manufacturers are laying greater emphasis on in-cabin filtration. Freudenberg Filtration Technologies (FFT) India has tapped this opportunity by introducing advanced in-cabin air filtration solutions and services targeted at offering surface protection in vehicles. The new range is backed by ISO18184 tests conducted by Guangzhou Institute of Microbiology, in China. The tests have concluded that FFT’s micronAir® proTect line filters offer a unique anti-viral filter layer capable of deactivating 99.9 per cent of viruses as per Ashok Pandey, Head, Automotive Filters at Freudenberg Filtration Technologies, India. “We at FFT believed that the first step to preventing viral airborne aerosols from causing harm was to produce a highly efficient cabin filter that directly filters them from the ambient air,” he averred. “Secondly, to inactivate the critical virus load by an antiviral filter media layer to keep the passengers safe,” he stated. The company, according to Pandey, is pursuing the penetration of the new range, on priority, having reached pre-Covid levels of production for most segments.

With an experience of more than three decades to leverage for the in-cabin’ air-filtration range, Freudenberg is seen shifting the focus from the drive train to vehicle occupants. “With the invention of the first cabin air filter in 1989, Freudenberg Filtration Technologies has invested huge resources in terms of research and product development. “We are catering to the ever-evolving needs and situations thus setting new standards in health protection and safety within vehicles,” asserted Pandey. Comparing High-Efficiency Particulate Air (HEPA) filters with cabin air filters, he opined that the former (HEPA) are rarely used. “They form just one element of the holistic hygiene concept. Their filter properties alone do not automatically translate into effective anti-virus protection for passengers since vehicle cabins completely differ from medical cleanrooms,” he opined.

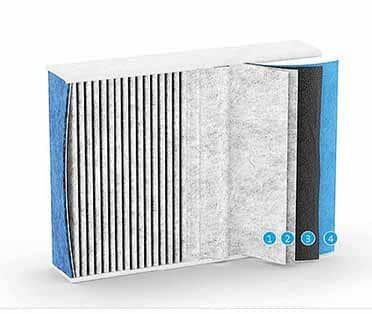

micronAir® cabin air filters

Despite emissions getting cleaner with the rollout of EuroVI/BSVI emission norms in India, Pandey explained that a major chunk of particulate emissions would continue to be a threat. He blamed factors like environmental change, industrial pollution and agricultural residue for the menace. “In closed environments like vehicle interiors, there is a higher risk of infection through inhalation. Therefore, filtering airborne aerosols is key for safety,” he cautioned. “The filtration acts as an effective shield against airborne aerosols transmitting pathogens such as H1N1 and HCoV-229E,” he claimed.

The filtration process works such that the virus is rendered inactive by the antiviral filter media layer where the viruses are made to interact with a fruit extract acidic environment. “Once captured on the filter, the viruses are inactivated through a two-pronged approach based on natural fruit extracts to prevent secondary contamination. The reaction causes the rendering or denaturation of the virus’ protein structure, in turn, restricting the pathogen from infecting human cells,” he explained. It is the filtration system and the air exchange rate that decide the efficiency of the filter in ‘recirculation’ mode, where it is said to eliminate the viruses. This needs to be backed by a frequent replacement cycle for optimum protection. “Before the launch, these filters have been extensively tested in labs and also in the field by almost every car manufacturer,” Pandey assured.

Four-layer filtration

The new range is made up of a unique multi-layer design that effectively filters, captures and suppresses noxious environmental gases as well as inorganic and biological particles and aerosols. The first two layers (particle filters) capture most of the ultrafine aerosols, fine dust and microorganisms like fungal spores. The optional third layer (a combi filter) made of activated carbon protects against harmful gases and reduces unpleasant odour coming in from interior emissions. An innovative, fourth functional layer coated with a unique fruit extract basis deactivates nearly 100 per cent of the detected viral load thus preventing the release of active viruses back into the cabin air.

This layer is claimed to be free of nano-silver ions and offer high long-term stability. These cabin air filters come with a micronAir Gas Shield developed with three distinct formulations to tackle varying types of pollution. The micronAir® proTect line filter captures aerosol droplets and droplet nuclei within 0.05-16 μm range. As per the recent studies by the World Health Organization (WHO), these aerosols contain the critical virus load, causing harm during breathing, talking, coughing or sneezing.

Engine intake filter

Combustion engines need clean air to maintain high performance but the ambient air in traffic situations is known to impair the combustion process with the sensors damaging the engine. As a resolution, FFT offers micronAir engine intake air filters claimed to offer outstanding filtration properties and energy efficiency values. With up to 150 per cent longer service life and improved initial arrestance, a measure of the ability of an air filtration device to remove synthetic dust from the air performance, these filters come with a large dust holding capacity. It offers favourable pressure loss properties over their entire service life causing the pressure difference to increase only slowly. It is also claimed to reduce the pressure losses, lower fuel consumption and CO2 emissions. Developed with fully synthetic materials, it also offers ageing and water shock resistance properties. The use of non-flammable materials is for improving fire-resistance.

Fuel-cell solutions

FFT has also developed small fuel cell-specific filters and humidifiers. Known to react sensitively to salts, nitrous oxides or compounds with sulphur or ammonia, which can enter the process via the intake air, the new range protects sensitive components. The micronAir filters protect the catalyst material and the membranes used in the stack and system components from contaminant gases and particles. A high arrestance performance ensures lower pressure losses, reliable processes and maximum service life for the fuel cell components. Reliable membrane humidification or a high-quality humidifier is crucial to maintaining fuel cell drive efficiency. It ensures a flawless reaction and is claimed to prevent early degradation as an outcome of the electrolyte drying out.

FFT offers long-lasting humidifiers with exceptional water transfer rate at a low-pressure drop and guarantees stable humidification. The hollow fibre technology enables various housing geometries claimed to be tested in real-world scenarios. It is optimised and adapted as per the system requirement without any major investments. On the filters eliminating the need to wear a mask while commuting in a vehicle powered by the FFT filter, concluded Pandey, “for safety purposes, passengers will still need to wear a mask as it is a well-known fact that the infection can transmit through greater than a single probable cause.” ACI

——————————————

Watch out for the upfront interaction with Mr Ashok Pandey, Head, Automotive Filters at Freudenberg Filtration Technologies, India, in the upcoming issue of Auto Components India.

Leave a Reply