Pune-based Atlas Copco Tools and Industry Assembly Solutions launched a new range of cordless smart battery nutrunners.

Story by: Deven Lad

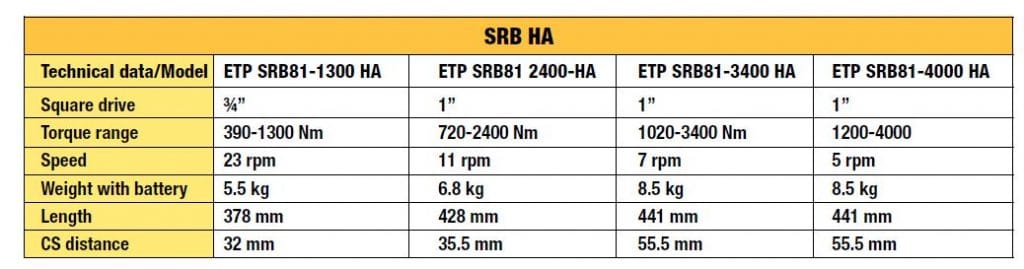

A torque wrench or a nutrunner is a popular go-to tool for working on fasteners like bolts or nuts with a controlled and specific torque. Taking into consideration its utilitarian features, Atlas Copco Tools and Industrial Assembly Solutions of Pune-based Atlas Copco (India) Ltd., launched a new range of cordless smart battery nutrunners. Aimed at critical industrial applications, it is a step up from the older generation of hydraulic wrench methods. The new range – SRB HA, is claimed to improve upon the expensive and time-consuming installation and maintenance processes associated with the older generation of nutrunners. Claimed to be an industry first, with a dual-trigger, it minimises the risk of a finger pinch injury and significantly enhances the accuracy levels of the current-controlled counterparts. Averred Chandrashekhar Pathak, Business Head India from the General Industry Segment of Atlas Copco Tools, and Industrial Assembly Solutions, “Presently most of the high torque battery tools available in the market are current-controlled tools. The accuracy of such current-controlled tools is questionable since the delivered torque output is far from the desired target torque.” “In several industries such current-controlled tools are barred from final tightening as they are not considered reliable enough,” he said. The nutrunner range is powered by Lithium-Ion 36V battery technology with charging and health indicators.

A torque wrench or a nutrunner is a popular go-to tool for working on fasteners like bolts or nuts with a controlled and specific torque. Taking into consideration its utilitarian features, Atlas Copco Tools and Industrial Assembly Solutions of Pune-based Atlas Copco (India) Ltd., launched a new range of cordless smart battery nutrunners. Aimed at critical industrial applications, it is a step up from the older generation of hydraulic wrench methods. The new range – SRB HA, is claimed to improve upon the expensive and time-consuming installation and maintenance processes associated with the older generation of nutrunners. Claimed to be an industry first, with a dual-trigger, it minimises the risk of a finger pinch injury and significantly enhances the accuracy levels of the current-controlled counterparts. Averred Chandrashekhar Pathak, Business Head India from the General Industry Segment of Atlas Copco Tools, and Industrial Assembly Solutions, “Presently most of the high torque battery tools available in the market are current-controlled tools. The accuracy of such current-controlled tools is questionable since the delivered torque output is far from the desired target torque.” “In several industries such current-controlled tools are barred from final tightening as they are not considered reliable enough,” he said. The nutrunner range is powered by Lithium-Ion 36V battery technology with charging and health indicators.

Zero-defect assembly, maintenance and smart operations

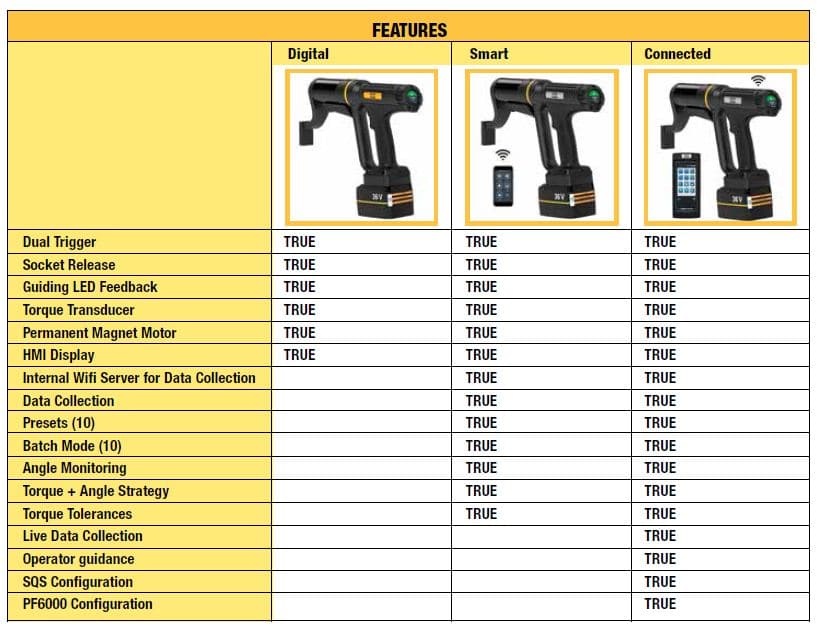

Atlas Copco is set out to make the erstwhile expensive, time-consuming operations of the hydraulic wrench faster and cost-effective. The new nutrunner range is claimed to have helped the company achieve the goal with a proven tensor motor technology. Notably, the company has addressed operator safety and comfort requirements. Designed ergonomically, SRB HA smart battery nutrunner is on offer in three models. The new range offers clear operator feedback using multi-functional LEDs and the status display (OK/NOK) messages based on torque and angle readings. The entry-level SRB HA digital version, for instance, features a ‘Set and Go’ function that is known to make it ready for use.

Atlas Copco is set out to make the erstwhile expensive, time-consuming operations of the hydraulic wrench faster and cost-effective. The new nutrunner range is claimed to have helped the company achieve the goal with a proven tensor motor technology. Notably, the company has addressed operator safety and comfort requirements. Designed ergonomically, SRB HA smart battery nutrunner is on offer in three models. The new range offers clear operator feedback using multi-functional LEDs and the status display (OK/NOK) messages based on torque and angle readings. The entry-level SRB HA digital version, for instance, features a ‘Set and Go’ function that is known to make it ready for use.

The smart and connected models feature an internal Wi-Fi server that allows the operator to connect the tools to any mobile device. It is claimed to enable torque, angle and batch data collection without the need for additional software. To further enhance the functionality and process control, the SRB HA features an accessory bus for a barcode scanner. It can also be integrated into overlying systems for live data feed and analysis. In addition, the connected model can also be connected to the PF6000. This enables the user to send a live feed to the controller and or another system in a bid to enhance process control and traceability. Standout features of the nutrunner, explained Pathak, include a strain gauge transducer and an inbuilt, Human-Machine Interface (HMI) with a digital display to show the real torque. “The programming and data collection capabilities will deliver significant value to our esteemed customers owing to its super-fast tightening speeds, low noise, enhanced battery capacity and high overheat limits,” he opined. ACI

Leave a Reply