Dr Srinivas Gunti and Dr Shankar Venugopal write on the automotive lightweight, technology roadmap, composites, electric vehicles, and optimisation with a long-term view.

The rate at which the number of ground vehicles is increasing will result in substantial environmental pollution, depletion of non-renewable energy sources and cause sustainability issues. According to a recent study [1], there would be two billion new vehicles reaching roads across the globe by 2040 and this would lead to multiple issues, namely, environmental pollution, energy, infrastructure issues etc. The Indian government came up with stringent emission regulations in the case of ICE platforms and offered subsidies for those who are driving green initiatives (Manufacturing of EVs). The power requirements posed by vehicle acceleration demands, gradeability conditions, and rolling resistance of the wheel are proportional to the vehicle weight and the most fundamental way of improving the vehicle level fuel economy in the case of ICE and range in the case of Battery Electric Vehicles (BEVs) is by reducing the overall weight. For the automotive OEMs, some of the key drivers for exploring lightweight technologies are:

a) Meeting CAFÉ Requirements (ICE Platforms) and ensuring energy efficiency

b) Eliminating Range Anxiety in case of e-Mobility

c) Sustainability and Reduction of Carbon footprint

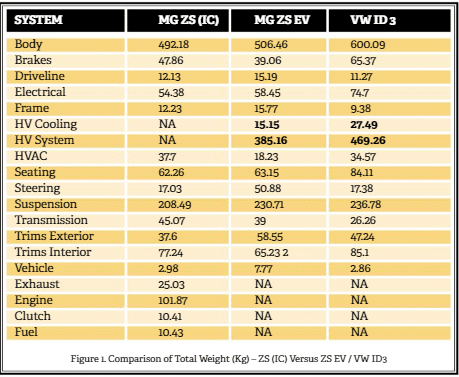

As we aim towards a circular economy, lightweight strategies are becoming more important and their objectives are focused on energy efficiency, reducing carbon footprint and improving cost economics and affordability aspects. With the focus on EVs, there will be a lot more demand for improving energy efficiency and reducing costs through lightweighting. Figure 1 shows a comparison of the total weight of the vehicle “while converting an ICE Based to an EV”. It is noted that there would be a 20 per cent increase in vehicle weight while converting the ZS ICE to ZS EV. This increase in weight is due to the addition of high-voltage systems and their cooling systems. This increase in the weight of an EV leads to a significant increase in product cost and range anxiety. There is a strong need to develop an eco-system that assists in developing and implementing lightweight technologies and this requires the creation of a clear-cut lightweighting technology road-map in the context of the Indian eco-system.

As we aim towards a circular economy, lightweight strategies are becoming more important and their objectives are focused on energy efficiency, reducing carbon footprint and improving cost economics and affordability aspects. With the focus on EVs, there will be a lot more demand for improving energy efficiency and reducing costs through lightweighting. Figure 1 shows a comparison of the total weight of the vehicle “while converting an ICE Based to an EV”. It is noted that there would be a 20 per cent increase in vehicle weight while converting the ZS ICE to ZS EV. This increase in weight is due to the addition of high-voltage systems and their cooling systems. This increase in the weight of an EV leads to a significant increase in product cost and range anxiety. There is a strong need to develop an eco-system that assists in developing and implementing lightweight technologies and this requires the creation of a clear-cut lightweighting technology road-map in the context of the Indian eco-system.

Automotive Lightweighting Road-map

In order to ensure the eco-system readiness that will assist various OEMs and suppliers to implement their short-term and long-term product strategies Indian National Academy Engineering (INAE) gave Dr Shankar Venugopal (on of the authors) the opportunity to lead the technology road mapping effort fo automotive lightweighting. A core team was formed and a series of brainstorming sessions were conducted involving Material Scientists, CAE, Design and Manufacturing experts from the Industry, academia and start-ups. Figure 2 shows the snapshot of various organisations participated in the ideation.

Automotive Lightweighting Strategies

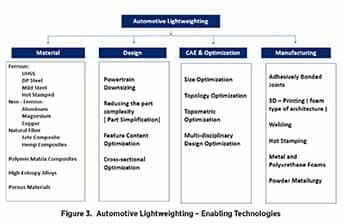

Figure 3 shows various methods of automotive lightweighting: through optimal material selection, design simplification, Computer Aided Engineering (CAE) and using advanced MDO Based Optimisation and manufacturing methods.

Material Innovations (Steels, Aluminum Magnesium Alloys and Composites)

Steels

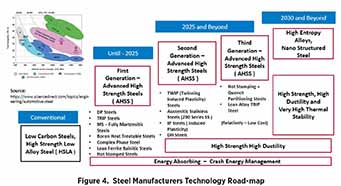

Figure 4 shows how steel manufacturers are evolving and presently we see a lot of research in the area of third-generation steel that can do a trade-off between cost and material properties. There will be a significant increase in the use of ‘Hot stamped steels’ that have the potential to reduce the gauge of the structural members while meeting the crash, durability and NVH requirements.

Aluminium, Magnesium Alloys and Composites

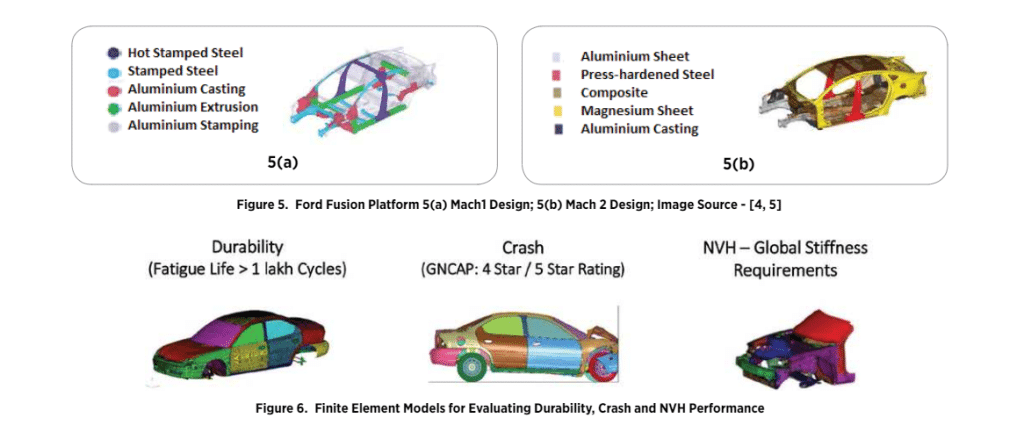

Figure 5 shows a study done [2,3,4,5] by the US Department of Energy (DoE) on two different designs (Mach – I and Mach – II). Mach I design made of Aluminium and UHSS realized a weight saving of 23.5 per cent with respect to baseline design (Ford Fusion – 2013) and the Mach 2 design made of Magnesium, Aluminium and Lightweight composites realised a weight saving of 50 per cent. Authors [6,7,8,9] have explained in detail the usage of Ultra High Strength Steels (UHSS), Aluminium and Magnesium Alloys, and Hybrid Composites (CFRP & GFRP), for automotive lightweighting applications. The use of thermoplastic and thermoset plastics for structural applications has been discussed in detail in the literature [10, 11]. Case studies on Powertrain lightweighting are discussed in detail [12, 13].

Design

Minimising the product and part complexity, powertrain downsizing, moving towards composites with a single-part construction by eliminating the joineries, optimising the feature content, etc. will help reduce the finished product costs and complexity. Authors [14, 15, 16, 17] explained the design, CAE and Testing aspects of the automotive body systems. Lightweighting can be achieved through cross-sectional optimisation through fundamental design calculations considering crash, durability and NVH requirements. The use of advanced Topology and Topometric Optimisation Methods [18] will assist in achieving significant weight reduction of vehicle structures.

CAE, Optimization and ICME

Advanced CAE methodologies [19,20,21,22,23] and Multidisciplinary Multi-objective Design Optimisation (MMDO) procedures can be used for lightweighting automotive structures. AI and Reduced Order Modeling (ROM) based optimisation methodologies will assist in “quickly solving” full vehicle finite element models that involve a large number of design variables, multiple performance constraints and multi-objective optimisation requirements. Figure 6 shows three different ‘Finite Element Models’ that were created to validate various Design Verification Plans ( DVPs ) pertaining to durability, NVH and crash safety.

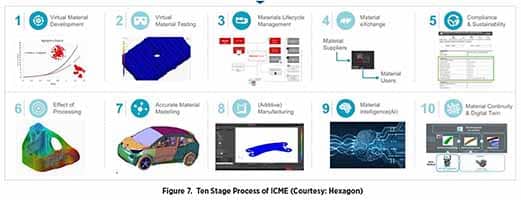

Integrated Computational Materials Engineering:

There is a need for integrating atomic/molecular scale models, micro and macro scale models and the full vehicle finite element models in order to improve the fidelity, prediction accuracy, optimisation capabilities and credibility of the numerical models. Figure 7 shows a 10-stage process (Courtesy: Hexagon) that integrates models at different scales, material libraries and manufacturing data threads [24]

Manufacturing

Selection of the right manufacturing method and fabrication procedure is very critical for achieving lightweighting. Authors [25] explained in detail the manufacturing aspects of lightweight alloys. Based on cost optimisation, certain components can be made by joining hot stamped and hot rolled steels using different welding techniques. For the part with increased complexity, the castings process would be recommended, in some cases, extrusions will be more economical and use advanced joining methods like friction stir welding, Self-Piercing Riveting (SPR ) used for integrating dissimilar metals, Laser Welding Blanks [26], adhesively bonded joining technologies and modelling methodologies [27,28,29], and additive manufacturing technologies, will assist significantly. Good quality resin that can sustain 150 degrees Celsius are imported and there is a need for developing these systems in India. The recycling eco-system of carbon cycle composites is to be developed in India.

Selection of the right manufacturing method and fabrication procedure is very critical for achieving lightweighting. Authors [25] explained in detail the manufacturing aspects of lightweight alloys. Based on cost optimisation, certain components can be made by joining hot stamped and hot rolled steels using different welding techniques. For the part with increased complexity, the castings process would be recommended, in some cases, extrusions will be more economical and use advanced joining methods like friction stir welding, Self-Piercing Riveting (SPR ) used for integrating dissimilar metals, Laser Welding Blanks [26], adhesively bonded joining technologies and modelling methodologies [27,28,29], and additive manufacturing technologies, will assist significantly. Good quality resin that can sustain 150 degrees Celsius are imported and there is a need for developing these systems in India. The recycling eco-system of carbon cycle composites is to be developed in India.

Key – challenges in implementing lightweight technologies: Manufacturing Perspective

l Long development times to introduce new lightweight materials.

l Commercial feasibility.

l High life-cycle costs (Manufacturing Phase for advanced materials – Al, Mg and Carbon Fiber)

l Complex joining technologies

l HPRTM and CRTM are currently being imported and there is a need for investing in these technologies and indigenous.

l Availability of quality suppliers and scalability

l Availability of quality suppliers and scalability

l Need OEM support to try out these materials on few parts (Proof Of Concepts)

l Investment in die design and manufacturing

Requires a change in the line and the infrastructure

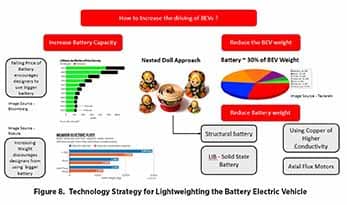

Lightweighting of Battery Electric Vehicles: Technology Strategy

BEVs weigh more

The demand from users for long driving range makes it necessary to use bulky batteries and as a result, the current generation of BEVs are heavier than their ICE counterparts. Initially, the EV battery was expensive, but the lithium-ion battery price has been reduced by 90 per cent over the last decade [30]. And their energy density has more than tripled in the last two decades. Most EV battery technology developments have focused on increasing the distance an electric car can travel on a single charge and boosting the car’s power. For example, when Nissan brought

to market a long-range version of its flagship Leaf electrical vehicle, they demonstrated triple the range (364 km) and double the horsepower (214 hp). But its weight has grown, too, by 14 per cent (more by 550 kg). The electric version of Ford’s F-150 weighs 700 kg more while in the case of Kona, the weight increase is about 300 kg [31]. In the case of Tesla’s Model S, we realise that the battery pack contributes to ~ 29 per cent of the vehicle weight (followed by the electric motor which contributes about 23 per cent) [32].

Can we improve the driving range without increasing the battery capacity?

In ICE vehicles, a 10 per cent weight reduction yields about six-eight per cent fuel efficiency improvement. A 10 per cent weight reduction for an electric vehicle can improve the electric range by 13.7 per cent. Reducing the weight of an EV allows the vehicle designer to improve electric range (while maintaining battery size/cost), reduce battery size/cost (while maintaining electric range), or find the optimal balance to meet consumer expectations in the specific vehicle segment [33, 34]. Scientists at the Fraunhofer Institute for Structural Durability and System Reliability (LBF) have reduced electric vehicle battery weight by changing the material of the battery pack casing. Using fibre-plastic composites to replace the aluminium casing of current battery packs, they were able to reduce the weight of the battery pack by 40 per cent [35]. Innovations that reduce the weight of the electric motor include Axial flux electric motors (flat, round devices) that are lighter and more efficient than conventional cylindrical ‘radial flux’ motors. Because the motor is more efficient, it can extend the range of an electric vehicle up to seven per cent, or because it uses less power it allows carmakers to take out some of the heavy batteries and reduce their vehicle’s weight by up to 10 per cent, he added [36].

Whenever we want to improve the driving range of EVs, we have two choices – either increase the battery capacity or reduce the weight of the vehicle. If we decide to reduce the weight of an EV by introducing a new material, design or manufacturing process, then we should also consider the additional cost incurred by introducing these changes. A rule of thumb for EV designers can be that a one-kilogram weight reduction should not cost more than USD five. Lux Research predicts that battery pack energy densities will increase by about 15 per cent over the next decade. This increased energy density can be used to either extend a vehicle’s range by keeping battery size the same or reduce cost by shrinking the size of the battery pack. Lux determined that for lightweighting to be a cost-effective solution against batteries by 2030, it will need to cost, on average, less than USD five per kilogram of weight saved [37]. For each BEV, Lux Research modelled two scenarios – optimising for range or optimising for cost. For each scenario, they calculated the cost of adding one kilometre of range via increased pack size versus the amount of weight reduction needed to increase the range by one kilometre. By comparing the cost of increasing range with batteries to the weight reduction needed to make the same change, they calculated a lightweighting benchmark. Lightweighting must cost less than this benchmark to be an effective way to increase range – otherwise, it will make more economic sense to simply increase pack size. While there is some variation, the cost of lightweighting in 2030 must be less than USD five per kilogram saved on average [38].

Copper in EVs

A teardown analysis of the Chevy Volt (EV) Vs VW Golf (ICE) revealed that the electric Bolt uses 80 per cent more copper than the Golf. Most of this extra copper is used in the electric motor of the EV. The copper coil in EV’s drive motor converts electrical energy (provided by the battery) into mechanical energy (required by the wheels). Typical EV motors can use more than a mile of copper wire in their stator windings. Copper wires are also used to connect various electronic components and the battery pack [39]. Researchers, from the US Government’s Pacific Northwest National Laboratory (PNNL), have developed a process that, they say, can boost the conductivity of copper wire by about five per cent, thus either improving the efficiencies of electric equipment such as motors or reducing their weight while operating with the same efficiency. They have teamed up with General Motors to test the improved copper wire in components for vehicle motors. The improved performance of higher conductivity copper, achieved by adding graphene, could be a disruptive approach to lightweighting and/or increasing efficiencies for any electric motor or wireless vehicle charging system [40].

Solid State Battery

The difference between a traditional battery and a solid-state battery is in its electrolyte: by using a solid material for the electrolyte between the anode and the cathode, battery makers can increase energy density (and therefore driving range), or reduce battery weight. Solid-state battery technology, Volkswagen claims, would more than double the capacity compared with the brand’s current lithium-ion batteries, boosting the range of the e-Golf from its current 186 miles (NEDC) to 466 miles [41].

Structural Battery

Elon Musk announced, during Tesla’s Battery Day, that its battery pack will be integrated into the chassis so that it provides mechanical support in addition to energy, a design that Musk claimed will reduce the car’s weight by 10 per cent and improve the range by 14 per cent. He hailed Tesla’s structural battery as a “revolution” in engineering [42]. Structural batteries are referred to as ‘Massless’ energy storage since, in essence, the battery’s weight significantly reduces when it becomes part of the loadbearing structure. Research too has proved that this type of multifunctional battery could considerably reduce the weight of an electric vehicle. Researchers from the Chalmers University of Technology have designed a structural battery that performs ten times better than its peers. A structural battery contains carbon fibre that serves simultaneously as a conductor, an electrode, and a load-bearing material. Chalmers university’s latest research breakthrough paves the way for essentially ‘Massless’ energy storage in electric vehicles and other battery-powered applications [43].

General Motors uses the nested doll approach for its Ultium battery packs, mounting thin metal pouch-type cells into hard metal modules or ‘cans’ which in turn are inserted into a large pack that is nestled between the frame rails of its new Hummer EV. Tesla Motors has designed a structural pack for its Model Y that does away with modules, bonding the large-format cylindrical battery cells together with structural adhesive and sandwiching them between two metal plates, which in turn are connected to the front and rear cast-metal structures of the vehicle [44]. Figure 8 shows the lightweighting technology strategy of a BEV platform.

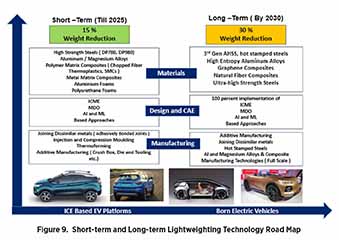

Short-term and long-term lightweighting technology roadmap: Proposed recommendations:

Figure 9 shows, how the Lightweighting road-map is aligned to the manufacturing of ICE Based EV Platforms and the Born Electric Platforms. The proposed short-term and long-term lightweighting strategy will enable the OEMs to deliver their product strategy. Achieving a 15 per cent weight reduction in the production vehicles by 2025 and a 30 per cent weight reduction by 2030 w.r.t the baseline designs, through the multi-material solutions, advanced CAE-based optimisation and manufacturing methods can be a meaningful and achievable target.

l In order to achieve the short-term objective of 15 per cent lightweighting by 2025 – the government of India, OEMs, suppliers and academic institutions to come together to deliver vehicle-level Proof of Concept by developing a Lightweight Passenger Car Platform (ICE and EV). The mode of collaboration would be through – Significant Research grants budgeted by the Ministry of Heavy Industry, Department of Energy and OEMs.

l To achieve the long-term objective of 30 per cent lightweighting by 2030 – government of India, OEMs, suppliers and academic institutions to write research proposals in the area of ICME, additive manufacturing, advanced lightweight materials, advanced computational engineering, optimisation methods and advanced manufacturing methods. Government to promote automotive manufacturers, suppliers, start-ups and academic institutions by providing huge incentives, subsidies and tax concessions on automotive lightweighting projects. OEMs to have special research and innovation cross-functional teams, new roles to be created, and capability-building initiatives in the area of automotive lightweighting to be accelerated.

Acknowledgements

Authors thank the Indian National Academy of Engineering (INAE) for giving Dr Shankar Venugopal (one of the authors) the opportunity to lead the technology road mapping effort for automotive lightweighting. Both the authors (SV and SG) thank Mr Ram Sitaraman (Mahindra Research Valley) and Dr K Anand (Deakin University India Center) for being part of the core team and driving the ideation with experts across industry, academia and government. The authors thank the experts from IIT Madras, IIT Hyderabad, IIT Kanpur, IISc Bangalore, Deakin University (Australia), Sabic, Dow Chemicals, JSW Steel, Hindalco Steel, Tata Steel, Mahindra & Mahindra, Ashok Leyland, Tata Motors, CSIR labs etc for participating in the brainstorming sessions and sharing their rich insights.

References

1. https://www.weforum.org/agenda/2016/04/the-number-of-cars-worldwide-is-set-to-double-by-2040.

2. Schutte, C., “DOE Focuses on Developing Materials to Improve Vehicle Efficiency,” SAE Technical Paper 2015-01-0405, 2015, doi:10.4271/2015-01-0405.

3. Skszek, T., Zaluzec, M., Conklin, J., and Wagner, D., “MMLV: Project Overview,” SAE Technical Paper 2015- 01-0407, 2015, doi:10.4271/2015-01-0407.

4. https://www.energy.gov/sites/prod/files/2015/06/f24/lm072 skszek_2015_o.pdf.

5. https://www.energy.gov/sites/prod/files/2014/07/f17/lm088_skszek_2014_o.pdf.

6. C.D. Horvath, Chapter 2 – Advanced steels for lightweight automotive structures, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), Woodhead Publishing in Materials, 2021, Pages 39-95.

7. Alejandro Graf, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), Chapter 3 – Aluminum alloys for lightweight automotive structures, Pages 97-123.

8. B.R.Powell, P.E.Krajewski, A.A.Luo, Chapter 4 – Magnesium alloys for lightweight powertrains and automotive structures, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), 2021.

9. Maki, C., Byrd, K., McKeough, B., Rentschler, R. et al., “MMLV: Aluminum Cylinder Block with Bulkhead Inserts and Aluminum Alloy Connecting Rod,” SAE Technical Paper 2015-01-1238, 2015, doi:10.4271/2015-01-1238.

10. P.K. Mallick, Chapter 5 – Thermoplastics and thermoplastic–matrix composites for lightweight automotive structures, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), 2021, Pages 187-228.

11. P.K. Mallick, Chapter 6 – Thermoset matrix composites for lightweight automotive structures, Materials, Design and Manufacturing for Lightweight Vehicles (Second Edition), 2021, Pages 229-263.

12. Corey, N., Madin, M., and Williams, R., “MMLV: Carbon Fiber Composite Engine Parts,” SAE Technical Paper 2015-01- 1239, 2015, doi:10.4271/2015-01-1239.

13. Kearns, J., Park, S., Sabo, J., and Milacic, D., “MMLV: Automatic Transmission Lightweighting,” SAE Technical Paper 2015-01-1240, 2015, doi:10.4271/2015-01-1240.

14. Bolar, N., Buchler, T., Li, A., and Wallace, J., “MMLV: Vehicle Durability Design, Simulation and Testing,” SAE Technical Paper 2015-01-1613, 2015, doi:10.4271/2015-01-1613.

15. Conklin, J., Beals, R., and Brown, Z., “BIW Design and CAE,” SAE Technical Paper 2015-01-0408, 2015, doi:10.4271/2015-01-0408.

16. Plourde, L., Azzouz, M., Wallace, J., and Chellman, M., “MMLV: Door Design and Component Testing,” SAE Technical Paper 2015-01-0409, 2015, doi:10.4271/2015-01-0409.

17. Jaranson, J. and Ahmed, M., “MMLV: Lightweight Interior Systems Design,” SAE Technical Paper 2015-01-1236, 2015, doi:10.4271/2015-01-1236.

18. Juan Pablo Leiva, Brian C. Watson and Iku Kosaka, A Comparative Study of Topology and Topometry Structural Optimization Methods Within the Genesis Software, 7th World Congresses of Structural and Multidisciplinary Optimization COEX Seoul, 21 May –25 May 2007, Korea.

19. P.K. Mallick, Chapter 10 – Designing lightweight vehicle body, Pages 405-432.

20. A. Deb, Chapter 11 – Crashworthiness design issues for lightweight vehicles, Materials, Design and Manufacturing for Lightweight Vehicles, Pages 433-470.

21. Experimental NVH Studies on Electric Powered and IC Engine Powered Passenger Vehicles – A Comparative Study for NVH Target Setting,”, R. S. Gunti, M. Bodla and S. Venugopal, 2019 IEEE Transportation Electrification Conference (ITEC-India), 2019.

22. Sairam Peddi, Raghu V. Prakash, Srinivas Gunti, Kanugula Raghu, EQUIVALENT ENERGY ABSORPTION (EEA) – A METHODOLOGY FOR IMPROVED AUTOMOTIVE CRASH & SAFETY DESIGN, Proceedings of the ASME 2021, International Mechanical Engineering Congress and Exposition, IMECE2021, November 1-5, 2021.

23. G.R. Srinivas, A. Deb, R. Sanketh, N.K. Gupta, An Enhanced Methodology for Lightweighting a Vehicle Design Considering Front Crashworthiness and Pedestrian Impact Safety Requirements, Procedia Engineering, Volume 173, 2017, Pages 623-630, ISSN 1877-7058.

24. https://www.e-xstream.com/flipbook/icme-for beginners/index.html?mkt_tok=MDc1LVdZVi02MjMAAAGG7vp19xjf0ooN-Nkfc8cs8mfNHYlAX- 3f49h-O2IQlBzB1BFDsMoGeoeYK8shweKb3ZtzJKe6r_qpYbjIH6O1IksUmXgw7o_X9MBJU6QW_D3E#p=20.

25. G.T. Kridli, P.A. Friedman and J.M. Boileau, Chapter 7 – Manufacturing processes for light alloys, Materials, Design and Manufacturing for Lightweight Vehicles, Pages 267-320.

26. https://www.automotivemanufacturingsolutions. com/voice/multi-part-integration-optimising-vehicle-structures/42553.article.

27. P.K. Mallick, Materials, Design and Manufacturing for Lightweight Vehicles, Chapter 8 – Joining for lightweight vehicles, Materials, Design and Manufacturing for Lightweight Vehicles, Pages 321-371.

28. Deb, A., Chou, C., Srinivas, G., Gowda, S. et al., “Behavior of Adhesively Bonded Steel Double Hat-Section Components under Axial Quasi-Static and Impact Loading,” SAE Technical Paper 2016-01-0395, 2016.

29. Gowda, S., Deb, A., Kurnool, G., and Chou, C., “Prediction of the Behaviors of Adhesively Bonded Steel Hat Section Components under Axial Impact Loading,” SAE Technical Paper 2017-01-1461, 2017.

30. EV prices set to go up as rising lithium-ion cell costs start to weigh in, Economic Times – https://auto. economictimes.indiatimes.com/news/industry/ ev-prices-set-to-go-up-as-rising-lithium-ion-cellcosts-starts-to-weigh-in/88140453.

31. Make electric vehicles lighter to maximize climate and safety benefits, Nature, October 2021 – https://www.nature.com/articles/d41586-021-027608?utm_medium=affiliate&utm_source=commission_junction&utm_content=en_textlink&utm_campaign=3_nsn6445_deeplink_PID100041175&CJEVENT=aeabe24386ad11ec81100a1c0a180513.

32. Tesla Model S weight distribution – https://www.teslarati.com/tesla-model-s-weight/

33. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering – William J. Joost – JOM volume 64, pages1032–1038 (2012) – https://link. springer.com/article/10.1007/s11837-012-0424-z.

34. A. Joshi, H. Ezzat, N. Bucknor, and M. Verbrugge, Optimizing Battery Sizing and Vehicle Lightweighting for an Extended Range Electric Vehicle (SAE Technical Paper no. 2011-01-1078, 2011).

35. The road to lightweight batteries, November 2020 – https://www.arbin.com/the-road-to-lightweight-batteries/

36. Electric supercars need to lose weight, power up and cool down. Nick Carey and Giulio Piovaccari, September – https://www.reuters.com/business/autos-transportation/electric-supercars-need-lose-weight-power-up-cool down-2021-09-27/

37. Reduced EV weight and cost predicted by 2030, Geoff Dobson, November 2020 – https://evsandbeyond.co.nz/ reduced-ev-weight-and-cost-predicted-by-2030/

38. Electric Vehicle Lightweighting 2030, Anthony Schiavo and Chris Robinson – https://www.luxresearchinc.com/hubfs/2020%20Executive%20Summaries/1%20-%20 2020%20Executive%2 Summaries%20-%20Press%20 Versions/Electric%20Vehicle%20Lightweighting%20 2030%20Executive%20Summary%20-%20press.pdf.

39. How much copper is in an electric vehicle, Nicholas LePan, November 2018 – https://www.visualcapitalist.com/how-much-copper-is-in-an-electric-vehicle/

40. “Better” Copper means higher efficiency electric motors, October 2020 – https://www.pnnl.gov/news-media/ better-copper-means-higher-efficiency-electric-motors.

41. Volkswagen aims solid state battery production 2025, Jimi Beckwith, June 2018 – https://www.autocar.co.uk/car-news/new-cars/volkswagen-aims-solid-state-battery-production-2025.

42. The batteries of the future are weightless and invisible, Wired, November 2020 – https://www.wired.com/story/the-batteries-of-the-future-are-weightless-andinvisible/

43. Will Massless Energy Storage Revolutionize Future Battery Tech?< FutureBridge – https://www.futurebridge.com/uncategorized/will-massless-energy-storage-revolutionize-future-battery-tech/#:~:-text=Structural%20batteries%20are%20referred%20 to,weight%20of%20an%20electric%20vehicle.

- https://www.reuters.com/business/autos-transportation understanding-structural-ev-bat – teries-2021-07-23/ ACI

The authors thank Ashutosh Joshi (Knowledge Resource Centre, Mahindra Research Valley) for supporting them with all the technical reference documents.

Dr Ranga Srinivas Gunti is General Manager, Head – Talent Development at Tata Passenger Electric Mobility (TPEM), Tata Motors. He is responsible for creating Talent Development Strategies, frameworks and processes for capability building pertaining to e-mobility. He received PhD from the Centre for Product Design and Manufacturing, IISc – Bangalore. His work resulted in 42 peer-reviewed journal/ conference publications, 6 Book Chapters and two US Patents. He is an Adjunct Faculty (Honorary Roles) at IIT Madras (Engineering Design Department) and Virginia Tech India.

Dr Shankar Venugopal is the Vice President at Mahindra & Mahindra. He leads technology innovation, intellectual property, and knowledge management for the automotive and farm Businesses. He holds a doctoral degree in materials science from the Indian Institute of Science. He has 20+ years of industry experience across GE, Dow, Honeywell, Cummins and Mahindra. He holds 10 US-granted patents and 10 Indian patent applications. As the Dean of the Mahindra Technical Academy, Shankar is focused on helping young engineers to build future skills.

Courtesy Mobility Engineering

Leave a Reply