ION Energy is optimising EV powertrains and energy storage systems through advanced battery management systems.

Story by: Deepti Thore

ION Energy Inc (ION) is on a mission! A mission to improve the life and performance of lithium-ion batteries. Be it battery packs powering EV powertrains or Energy Storage Systems (ESS) that are in vogue with economies the world over-committing to going fully electric by the turn of the decade. Co-founded by Akhil Aryan in 2016, Mumbai headquartered ION has conducted extensive research to conclude, by 2022 itself, global battery manufacturing capacity could hit 400 GWh. The company is betting big on the demand of Battery Management System (BMS) compatible with Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (LiMn2O4), Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2), Lithium Iron Phosphate (LiFePO4), Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) and Lithium Titanate (Li2TiO3) spanning low voltage to high voltage applications. Lead-acid or Ni-MH battery packs, however, are the exceptions in terms of compatibility.

ION Energy Inc (ION) is on a mission! A mission to improve the life and performance of lithium-ion batteries. Be it battery packs powering EV powertrains or Energy Storage Systems (ESS) that are in vogue with economies the world over-committing to going fully electric by the turn of the decade. Co-founded by Akhil Aryan in 2016, Mumbai headquartered ION has conducted extensive research to conclude, by 2022 itself, global battery manufacturing capacity could hit 400 GWh. The company is betting big on the demand of Battery Management System (BMS) compatible with Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (LiMn2O4), Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2), Lithium Iron Phosphate (LiFePO4), Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) and Lithium Titanate (Li2TiO3) spanning low voltage to high voltage applications. Lead-acid or Ni-MH battery packs, however, are the exceptions in terms of compatibility.

ION counts Airbus, Ola, Tata Motors, Wamtechnik, Okinawa Scooters (i-Praise Electric Scooter), Tork Motorcycles, and Electric Motion among others in its clientele, a testimony of its market penetration. With over 25,000 BMS deployments (out of which 15,000+ electric two and three-wheelers in India and Europe), are electric across two-wheeler EVs (12V) to electric excavators (xV) to a micro-grid storage system (1080V), ION’s technology, claims Akhil Aryan, Co-founder & CEO, ION Energy Inc., is directly responsible for helping companies save up to 40 per cent on electronics. “The industry being in its nascent stage, tier 1 and 2 automotive OEMs look for high-quality BMSs at a very competitive cost, and ION has managed to strike an optimum balance between low cost and high quality,” he averred.

Battery Management System

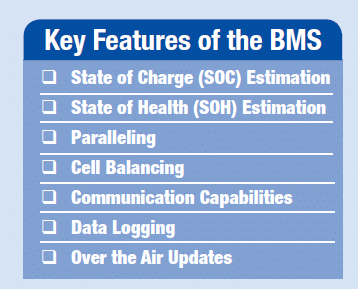

An efficient BMS unarguably guarantees a reliable and efficient battery pack. Explained Aryan, “ION’s approach, a software-first, full-stack one leverages advanced electronics, machine learning software and AI with its domain expertise in energy storage.” Notably, ION’s business model enables customers to buy or build custom BMS models. The BMS supports passive cell balancing claimed to ensure uniformity in the State of Charge (SOC) and voltages of the individual cells which maximise the capacity of the battery pack and improves life. Balancing the current range varies across the variants of its BMS units.

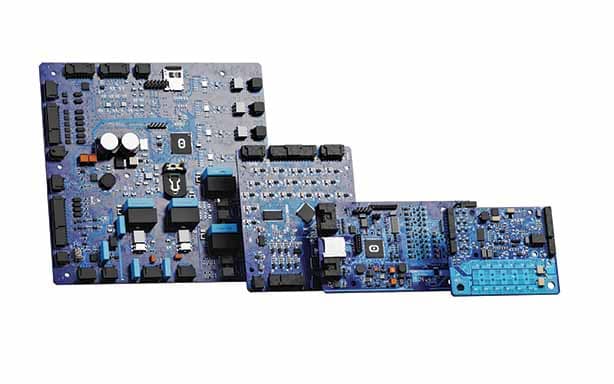

ION offers three BMS variants: FS-CT (Compact) designed for low voltage battery systems from 7.5V to 42V, FS-LT (Light) designed for battery systems from 12V to 100V and FS-XT (Extended) designed for high voltage battery systems from 13V to 900V offered with a one-year warranty.

The FS-CT is known to connect from six to 100 cells in series. The FS-LT connects from six to 25 cells in series and using a modular architecture, it is said to manage applications from 12V to 110V and is compatible with multiple battery chemistries. For instance, in electric scooters and rickshaws, known to run on 48V to 60V lithium-ion battery packs. It is also tested for EMI/EMC tests as per AIS004 guidelines to meet a critical requirement for electric vehicles. It also offers resistance to electromagnetic disturbances and enables safe functioning in environments with heavy electrical noise. The FS-XT especially designed for automotive and high precision applications uses a distributed BMS. It consists of a System Management Unit (SMU) or a Master Unit known to connect up to 40 Battery Monitoring Unit (BMU) or Slave Units. Each Slave Unit can further monitor six to 18 cells in a series configuration. It can also connect up to 18 batteries in a parallel configuration. The FS-XT boasts of high-voltage safety features such as IMD Integration, HV Interlock Lines, HV Measurement Channels and Weld Check.

The BMS manages the flow of current through a Power Distribution Unit (PDU) and is known to support both solid-state and electromechanical based PDUs. Aryan drew attention to the Telematics Control Unit (TCU) for remotely accessing battery asset status, health, and data for more in-depth analysis. “The TCU seamlessly interfaces the BMS with Edison Analytics to provide real-time data about battery health, status, warranty, and in the case of utility-scale Battery Energy Storage Systems (BESS), in energy dispatch,” he mentioned. The BMS with CAN Bus 2.0 A and B interface for charger control and system interface supports all baud rates ranging from 125 kbps to 1 Mbps. It also supports both standard and extended CAN IDs. The BMS is compatible with CAN-based chargers including Zivan, TC charger, Bassi charger and Dilong charger.

The BMS is backed by ION Lens, a smartphone application to interface remotely with ION BMS interface via Bluetooth. Through it, critical information of the battery like SOC, current, temperature and individual cell voltages can be accessed besides configuring and editing the configuration files. ION, additionally, offers services to help the companies design and engineer battery packs as per their specifications. It looks at various stages spanning cell selection, thermal management electro-mechanical assembly, structural design and the design analysis. Said Aryan, “The services extend to prototyping, quality analysis and testing as part of the end-to-end solutions involving a short-run production, supply chain and consistent assembly line set-up.” Successfully tested and validated hardware for IEC 61 000 (EMI / EMC) and IEC 61439-1:2011, the company, cited Aryan, is additionally helping its partners achieve certifications like IEC 62133, Basic UN38.3 and ARAI AIS 048 in Indian Automotive Industry.

Edison Analytics

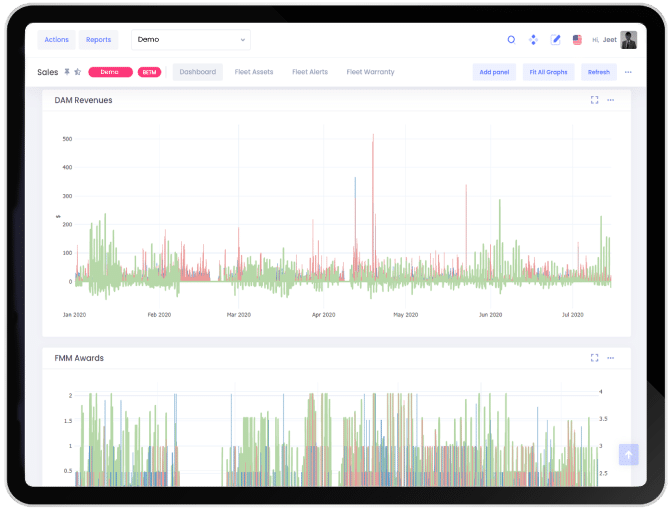

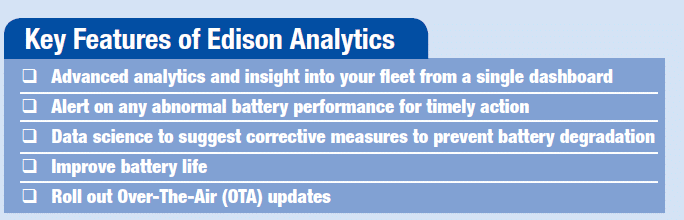

Through a CAN view, desktop software suite ION facilitates two-way communication with the BMS. “This paves the way for system configuration, real-time data visualisation, authentication and data transfer to the company’s battery intelligence platform – Edison Analytics,” explained Aryan. The BMS is also equipped with on-board memory storage known to log every data point of the battery pack collected. It is claimed to facilitate battery data archives of up to 20 years. To overcome the challenge of managing the data quantum, ION as per Aryan is relying on compression algorithms tailored to battery data acquisition. Physical parameters, events, errors relating to the performance of the battery pack are part of the data pool generated, he informed. The cloud-connected battery intelligence platform Edison Analytics allows engineers to access the data pool and help customers gain invaluable insights into the life and overall performance metrics of the battery.

Through it, customers can look forward to configuring the BMS to inturn match their application’s requirements with the battery’s capabilities. For instance, users can customise over 190 parameters relating to power distribution, ignition controls, balancing, charger control etc. “Our off-the-shelf products are ready-to-be-deployed and generally have all the latest features and hardware developments. If the customer needs custom features, it can take anywhere from a week to 6 months, depending on the type of feature update. For example, the software takes a week to 2-3 months and the hardware takes anywhere from a month to six months; these timelines depend entirely on the complexity and urgency of the requested features,” he claimed.

Battery Energy Storage Systems

The energy mix has evolved with the emergence of Variable Renewable Energy (VRE) sources. Battery Energy Storage Systems (BESS) are known to have enabled power system operators and utility providers to store energy for use at a later point and time thus enhancing the grid flexibility. With the global BESS markets displaying a lithium-ion battery monopoly, the need for intelligent management and operations is being felt. By modelling impedance (DC) the BESS is claimed to be capable of predicting if the batteries can fulfil the demand from the grid over their ageing. Among advantages are warranty validation, troubleshooting, bidding and energy arbitration, and record keeping. Explained Aryan, “At ION, we are overcoming the limitations of traditional systems and analytical tools to maximise the potential of these batteries.” “Our battery management and intelligence platform help operators optimise the cycle life and get better RoI on their BESS deployments,” he stated.

On optimal battery efficiency contradicting the pursuit of economies of scale argued to be crucial in bringing battery costs down, Aryan opined that both go hand-in-hand. “Eventually, the benefit has to roll into the total cost of ownership to the end customer,” he concluded. ION is witnessing strong traction in the EU and is expected to make announcements on the lines in the coming months. 100 per cent localised, ION is aiming to go beyond its offerings to contribute to the EV infrastructure as a whole, in 2022. ACI

Leave a Reply