Text & Photos: T Murrali & J Srikant

Bhiwadi based Halla Visteon Climate Systems India Limited (HVCSIL), the first manufacturing facility within its group and the second company in India to win the Shingo Recognition Award, has been setting benchmarks in quality and safety. The parent company is looking to take a leaf out of its initiatives to be implemented globally. Despite adding more products the company has been able to sustain zero ppm for more than 20 months in a row. The robustness of the plant is evident after a short tour.

HVCSIL has been a leader in India in radiators catering to the passenger car segment market leader Maruti Suzuki. The company has been extending its lead to other powertrain cooling products like the charge air cooler. It is able to do so due to its focus on improving local engineering capabilities, investing in capacities and investing in people. The main product from the Bhiwadi plant is the engine cooling module. The other products that are manufactured are charge air coolers, fuel delivery modules, EGR coolers and condensers.

All the products can be classified under heat exchangers with the exception of fuel delivery modules, which are catered to only for passenger vehicles and utility vehicles. Therefore, over two-thirds of the production is of engine cooling modules, which have aluminum based heat exchangers.

HVCSIL makes these heat exchangers based on two methods – mechanical type and the braced variety. Braced is better than mechanical in terms of performance, and is lightweight; however, from the ruggedness and durability perspective, mechanical type scores well. Mechanical is old technology and constitutes less than 10% of the production now at HVCC India. The braced heat exchangers have been manufactured since 1999. Major customer for this plant is Maruti. It also caters to Mahindra and Tier-1 company KSPT.

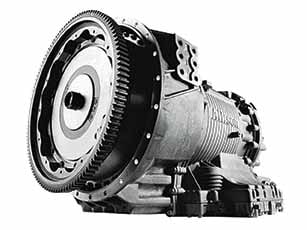

Engine cooling module assembly line

Engine cooling module assembly line

Manufacturing

The engine cooling module that the plant makes has two major components – the radiator, which is the aluminum heat exchanger portion of it, and the fan module (comprising of motor assembly going on the shroud) to provide the airflow across the heat exchanger. The company’s other locations bundle the condenser and charge air cooler under the engine cooling module.

The company out sources motors and some stamped parts. Besides, it also buys a few plastic parts including fan blades. While the company banks on suppliers who are single source for them, it also has secondary sources from around NCR. However, the aluminum sheets, which form part of the major portion of the radiator, are imported from Europe, China or Korea.

Leave a Reply