By: Richard Keller, Member of the Management at EMAG ECM GmbH

Downsising the engine has been a dominating trend in the automotive industry for years. Cylinder capacities are forever shrinking, whilst the application of turbocharging increases the pressure of the air-fuel mixture. And this affects all components involved. For an instance, the piston, which undergoes extreme stress in the modern engine, calls for an improved cooling system. For the drilling of the necessary bores, engine builders are increasingly using the ECM technology. This non-cutting production technology radically simplifies the whole process.

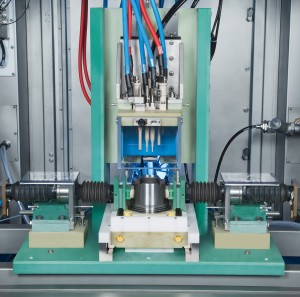

The development of an innovative piston design with improved cooling system presented a considerable challenge for the production planner of one sub-supplier in particular. How was he to drill the holes in the piston in one efficient, large-volume process? The use of classical boring processes was causing a real problem with the removal of the chips, as it proved very difficult to clean out the relevant cooling zones with absolute process integrity. “The customer came to EMAG with this problem, originally thinking of using our ECM deburring process. However, this idea supplied the impetus for the design of a machine that uses our innovative ECM process intelligently in the drilling of complex bores,” explains Richard Keller, Member of the Management at EMAG ECM GmbH.

Ideal for difficult bore transitions

It should not come as a surprise that the machine builders from Southern Germany rely on their ECM method for this application. The process is completely non-cutting. And that means no ridges or burrs – ideal conditions for homogenous bore transitions. The fact that a number of bores can be drilled simultaneously on the same workpiece (and, if required, even on a number of workpieces at the same time), ensures that the technology scores high when it comes to speedy processing. A DC or pulse source polarises the workpiece as positive (anode) and the tool as negative (cathode). An electrolyte solution that runs between the 2 removes metal ions from the workpiece. There are neither mechanical nor thermal stresses involved. As the shape of the tool cathode represents that of the hole to be drilled, material will only be removed at the desired points.

Simplified production process

At the ECM laboratory in Gaildorf, EMAG experts tested the efficiency and the accuracy of the drilling process on the piston beforehand. The detailed preliminary studies carried out here do not only assess the general feasibility of the application – for instance through material testing and by establishing the viability to hold given tolerances and to ensure reproducibility – EMAG also checks the economic viability of the ECM process compared to other processes. Based on the results of these checks and tests, they are able to quote actual cycle times and to define the machine concept most suitable for the component in question. This gives the customer a chance to assess whether the ECM process is the optimal solution for his particular production requirement. “This is surely a central aspect of the quality of our work. These accurate preliminary studies we offer to all our customers, of course,” confirms Keller.

That the subcontractor decided, on completion of the series of tests, in favour or the innovative ECM technology, has a lot do with the simplicity that ECM adds to the machining process. The process chain is noticeably shorter than with traditional machining methods. How? The bur-free ECM drilling process can be added at the end of a process chain, carried out on hardened components, if necessary, and requires no post-treatments. “This brings an enormous advantage to the whole production solution. In the end, it means that the customer saves himself the expense of having to buy a deburring machine and, at the same time, reduces the production area requirement,” underlines Keller.

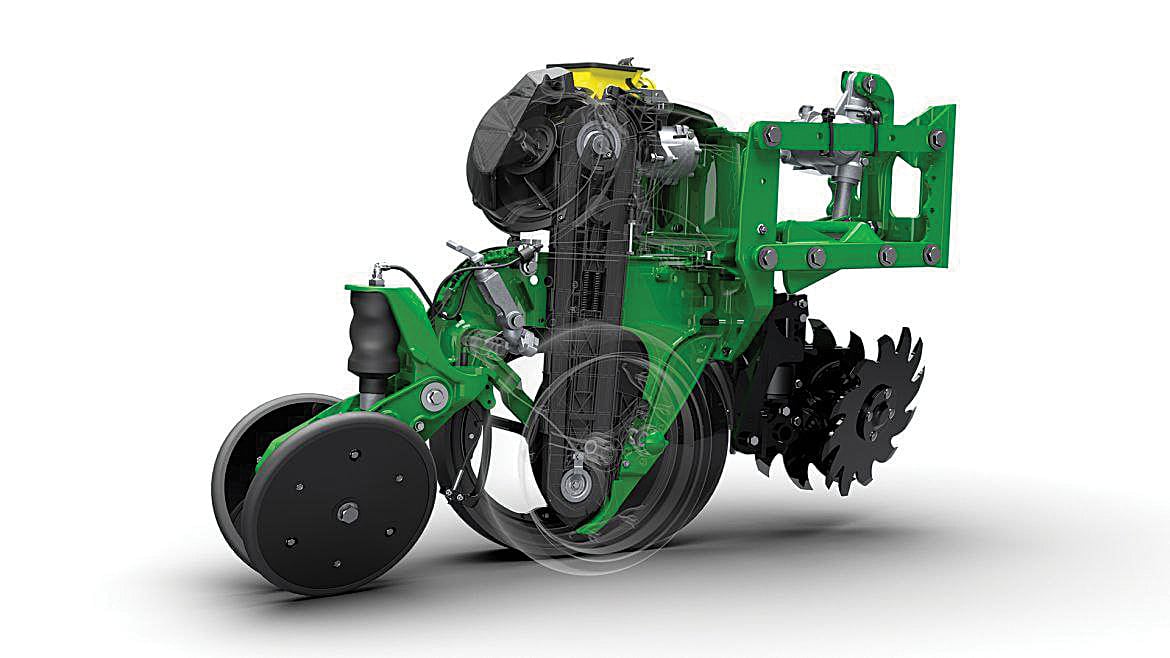

Passenger car sector

These and other advantages (for instance the minimal tool wear and the total absence of adverse thermal effects on the workpiece) brought the success story of the ECM drilling process in the commercial vehicle sector also to the attention of the passenger car sector. As a result, EMAG engineers developed, on request of an international automotive company, a tailor-made solution for the precision machining of camshafts. The oil holes on the shaft can be drilled with great precision and minimum tool wear using the ECM process. It is true to say that technological development like this support the success story of the process also in the passenger car sector. The search for fuel-efficient engines also changes the design of their integral components. Conventional drilling methods often come up against unsurmountable limits. ECM stands for the simplification of the process chain. “The ECM process is usually found at the end of the process chain and rounds it off cleanly, efficiently and without complications. It can be a very persuasive argument,” comments Keller.

Aircraft industry adopts ECM

With another step in the same direction, the experts at EMAG have succeeded in taking their success in the commercial vehicle and the passenger car sectors also to the aircraft industry. The ECM process as such has here been used successfully for years. Engine parts, blades and blisks are being finish-machined using the electro-chemical removal method. It makes for consistently good surface finishes. An extreme challenge is posed by materials such as Inconel. This tough nickel-based alloy can be cut only at the cost of heavy tool wear and extremely long cycle times, disadvantages that also apply to the drilling operation. A central engine part in Inconel has a large number of holes to be drilled. Until recently, the whole operation of the relevant chip-removing process took less than 40 hours. “Using ECM drilling technology, we can shorten the cycle time to approximately 10 hours. That represents a quantum leap for our customer’s production,” explains Keller. By the way, the ECM specialists in their laboratory at Gaildorf presented a preliminary study also for this application. It clearly showed the enormous improvement offered by this process. The first ECM drilling machine for the aircraft industry is presently at the design and implementation stage.

The ECM specialists at EMAG see a great future for this technology, something that also applies to the developing markets in Asia, America and Europe. When the automotive industry is planning a new production facility somewhere and is looking for efficient production processes, they frequently find they cannot do without ECM drilling, according to Keller. “Not only does this technology simplify the whole production process for pistons, camshafts, crankshafts and other components with complex bores and a demanding geometry, it also helps to keep investment costs low. Electro-chemical metal removal guarantees excellent component quality and low cycle times. We are convinced that these advantages will win out.” ACI

Leave a Reply