S Ravi, MD, Craftsman Automation takes us through his company’s

S Ravi, MD, Craftsman Automation takes us through his company’s

interesting journey in recent times.

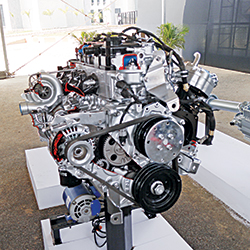

When do you plan to commence production of the cylinder block and head for the ALL – Nissan JV?

Ravi: We will commence commercial production of these two parts from the third quarter of the current fiscal. The objective is to roll them out in a ready-to-assemble condition. It is to this end that we are setting up a new assembly line at our Coimbatore factory at an investment of around

Rs. 100 crore.

You supply key powertrain parts to DICV. What has been your experience?

Ravi: We supply DICV key powertrain parts such as cylinder block and cylinder head for their heavy-duty engine, in fully finished condition. We were thrilled when DICV decided to audit us in order to source components. It had been beyond our imagination to have the German company source parts from us.

How do you plan to leverage this expertise to develop business in the future?

Ravi: Going forward, we are exploring opportunities to export fully finished cylinder blocks and heads. Encouragingly, we have recently

bagged an order from a large genset manufacturer in the US for the supply of machined cylinder blocks and heads, going into a V8 petrol engine.

We are currently developing castings in accordance with the plan to start series production within two years. Also, we are trying to get the engine assembly done at our Coimbatore facility and are in discussions with them for the same. Two other developments worth mentioning are, an order to deliver camshafts to an European OEM. Full-fledged supplies are slated to commence within a year. Besides, we have also received enquiry from a German automotive major to supply fully-finished cylinder blocks and heads.

Would Craftsman Automation want to set up a new facility to make cylinder blocks and head for the V8 petrol engine?

Ravi: We intend to create an assembly line within our Coimbatore facility. The US company has agreed on investing in special machinery to facilitate the process. We have in the past, created an assembly line for the Ashok Leyland – Nissan project. Currently, we are constructing a 60,000 sq.ft. shed at an investment of Rs. 20 crore as a part of our expansion strategy.

Since you seem to use lot of castings, did you consider establishing a foundry?

Since you seem to use lot of castings, did you consider establishing a foundry?

Ravi: We considered the option, and even acquired lands in Perundurai, Tamil Nadu. But, we have put those plans on hold, and have decided to focus on existing players who have requisite capacities.

Are you looking at expanding your product portfolio?

Ravi: As part of our expansion plan, we hope to get in to the manufacture of large moulds in order to put out products meant for automotive as well as non-automotive applications. Currently, we make moulds for smaller components especially for the electrical industry. Additionally, plans are on to foray into sand casting for the electrical industry, and we are tying up with a large MNC, to further the initiative. For now, we are strengthening our presence in the engineering space, which will complement our automotive business, and other product divisions like marine, storage, gearboxes and storage systems.

Due to stringent emissions regulations, cylinder blocks and heads are expected to be delivered in ‘spic and span’ condition. How do you ensure that these expectations are met?

Ravi: Since we machine over 3,000 cylinder blocks and 2,000 cylinder heads, we have developed special cleaning machines, with contemporary technology for the effective washing of engine blocks and heads that bear several cavities. It took us about 18 months to develop this machine which can pass the stringent ‘Millipore’ test.

Did Craftsman build this machine entirely on its own?

Ravi: Our understanding of the process of washing, along with expertise garnered in designing and building machines over a period of time helped, helped during the development of this machine. Currently, a cylinder block rolls out every 20 seconds from our nine assembly plants. We maintain a TAKT time of as low as four minutes, while registering zero-PPM levels. This is virtually unprecedented when it comes to the manufacture of cylinder blocks and heads for commercial vehicles. In some lines we handle nearly 90,000 units per annum capacity. A entire range of inspection facilities have been installed to help us churn out flawless cylinder blocks.

Since Craftsman deals with a large number of outsourced parts, how do you maintain quality?

Ravi: The company has installed a dedicated system to inspect all outsourced child parts. The dimensions, once measured are electronically recorded for future reference. In certain critical applications we have introduced software-driven poke yoke systems, wherein the product under assembly cannot pass on to the next station in the assembly line if a defect is detected. At present we are working on a new machine/inspection system that will deliver improvements in inspection and quality control.

Can you tell us about the new inspection system?

Ravi: Falcon Vision, a Hungarian company manufactures ‘vision inspection’ equipment for aluminum castings going into cylinder blocks and heads meant for passenger car engines. We are now working with Falcon Vision to develop an equipment that can carry out visual inspection for dimensions of cylinder blocks and cylinders heads going into commercial vehicle engines. The result of this joint effort is a robot wielding a camera that is programmed to measure dimensions of casting and machined portions. The camera captures images of every part of the cylinder block and head and subsequently compares them with bench marked dimensions. The robot also features a laser to precisely glean the depth of cavities. Besides, it also inspects for any unwanted foreign particles and alerts the operator should there be an anomaly. Through this mechanism, we not only improve quality, but also save time.

Will the new equipment help eliminate visual inspection?

Will the new equipment help eliminate visual inspection?

Ravi: The visual inspection system will propel us towards a zero defect state when it comes to the machining process. We have been working on this project for the last two years and hope that the equipment will be commissioned within a year. This will be the first visual inspection equipment in the world that is capable of checking dimensions of machined cylinder block and head made of ferrous castings for CVs and off-road applications. It can, however, inspect any machined part if the software is suitably configured. We plan to deploy this equipment in those places that warrant critical checking. The total cost of the equipment including development is estimated to be Rs. 10 crore.

Can you tell us about other business units of your company?

Ravi: We have three verticals – powertrain, engineering and products. Under powertrain, we cater to John Deere, Mahindra, TAFE, CNH and Escorts. While the engineering division of the company supports companies like GE Locomotive, Siemens, Bombardier as also others in the wind energy and printing sector. Under the products division, we sell engines for marine applications; gearboxes for industrial applications and small parts for satellite launch vehicles.

How do you manage such a diverse portfolio?

Ravi: We like a real challenge. We import basic engines from the likes of Mitsubishi and Hyundai, combine them with engine controls and sell the power pack to customers in the marine industry. Presently, we import three engine models from Mitsubishi (CM2.16 two cylinder – 16hp, CM3.27 three cylinder – 27.2hp and CM4.42 four cylinder – 42hp), and two from Hyundai (CM4.65 four cylinder – 65hp and CM4.80 four cylinder – 80hp). In fact, we have recently established a storage system business unit. Diversifying into different segments, helps us to strike a balance, especially if a particular sector is witnessing a slowdown.

Leave a Reply