Make in India

First of all, at the central government level, there is a genuine and continuous pressure to work on the theme of ‘Make in India.’ Based on his interactions with the Government he observes that there are many small but significant structural changes being attempted to ease doing business.

Enticing Entrepreneurs

From an entrepreneur’s view, you look for ideas, you look for outlets. When you walk through an exhibition of this size you look not only at technology, but also business opportunity. The machine tool industry is highly entrepreneur-driven while machine tool accessories are entrepreneur involved. Every time people come to exhibitions like IMTEX, a few entrepreneurs go back and start making something for the industry. It will also help existing entrepreneurs to scale up and motivate new entrants to experiment with new ideas. Also, the event will give several options to make products at competitive cost—for example, grinding substituted with hard part turning. Besides, local events help them get everything they need from international exhibitions, in their own language. This is the reason why a majority of the people visiting these exhibitions are entrepreneurs, and from small and medium enterprises.

IMTMA is confident that both IMTEX 2015 and Tooltech 2015 will facilitate business-to-business cooperation between manufacturers and users from backgrounds connected to metal-cutting manufacturing technologies. The exhibits hold promise and significance for all levels of manufacturing organisations—be it CEOs and entrepreneurs, middle-level management, senior executives, corporate planners and strategists, R&D specialists, shop floor engineers, supervisors and technicians, agents and dealers—spanning across industries including aerospace, automotive, railways, earthmoving equipment, among others. However, there is no buyer-seller meet as such. There will be a large chunk of people coming in for group participation; this year the event will have 9 group participations. Currently, at the association level, IMTMA is inviting delegations from different segments and countries. These include SIATI in Bangalore, ACMA, Ordnance factories and vehicle manufacturers. The organisers will support these delegations by helping connect with business partners.

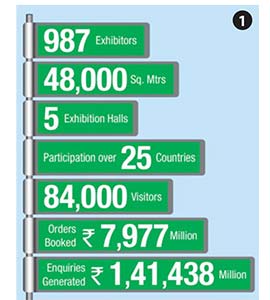

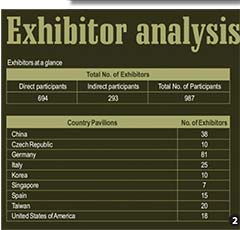

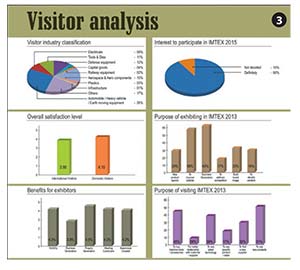

1. Highlights of 2013 Edition 2. 2013 Edition Exhibitor Analysis 3. 2013 Edition Visitor Analysis

Conference

A day before inauguration of the exhibition, IMTMA will be organising an interactive ‘International Seminar on Machine Technology’ related to the field of metal cutting focusing on expertise, innovations, technology and trends. The seminar will be broadly divided into concurrent sessions on various subjects pertaining to the metal cutting machine tool industry. Experts in the field from India and across the globe will share their knowledge at the seminar. This is just to propagate the technology— the technological leap and the directional change that is happening.

Academia Pavilion & Job Fair

An initiative of IMTMA to connect institutions with industry, the academia pavilion will have participation from leading engineering and technical institutions presenting their R&D capabilities. The event will also enable the machine tool industry to source skilled manpower.

Trend

Broadly, the events will present the emerging trends in the metal cutting industry. For instance, the current trend is to attain higher accuracy levels, which is driven by end-customers. End-customers, in the automotive industry, are going towards developing engines that can comply with the next higher level of emission norms. In the case of aerospace industry, it is moving from aluminium to titanium to composites; hence, the machine tools required to machine them would also need to have the capability, eventually making the entire ecosystem undergo a change. In terms of technology, there will be faster spindles, faster movement of machines, machines that are capable of dry machining and more matching with interactive software.

During the past decade the machine tool industry has been moving towards TPM-friendly machines. There was a trend in some applications to go for MQL (minimum quantity lubricant) machines that require only vapourised droplets of coolant to be sprayed, instead of litres of coolant. Many of these trends have a niche application and MQL finds a larger space.

The impending event will have more number of people displaying machines and accessories for aerospace parts, particularly data dimensioning, composites, tools and machines that have the capability to machine titanium, composites etc. The current capacities will be exhausted in a jiffy if the Defence Ministry takes some big-ticket decisions that would open the flood gate for over Rs 40,000 crore of buy-back commitments in the form of sourcing from India, concludes Krishnan. ACI

Leave a Reply