ACI Bureau

Cleveland CycleWerks (CCW), the US-based two-wheeler company, has ventured into the Indian market with its retro-inspired motorcycles Ace Deluxe and Misfit. The company has set up an assembly plant in Pune with an annual capacity of 35,000 units. It has plans for localisation and to make India-specific motorcycles.

Started in 2009 in Cleveland Ohio, the two-wheeler company was founded by Scott Colosimo, Jarrod Streng, and Curtis Ray with the vision to create a motorcycle with the custom feel and easy to customise. CCW has branches in 23 countries.

“We look at localisation in every country we sell our products. One of the hardest aspects of selling in the Indian market is the tariff. This gives us a big strain and we have to push our margin down. This also leads us to invest less in R&D and other areas. Therefore, localisation will play a major role. It may not happen immediately, maybe after six months. The absence of motor/engine manufacturers here is another big challenge. We have to source them from the US, Thailand or Italy. In India, it is going to be important for us to look at what we can do within our space and not push outside our comfort zone,” Scott Colosimo, Founder and CEO of Cleveland CycleWerks, told Auto Components India.

He said the Pune facility might not make the engines. For manufacturing a motor there should be a clean environment and a completely different set-up. The current engine manufacturers of CCW have their own space and they do not mix it with chassis and other components. Scott said his focus was on India, as “the market is everything that the company is looking for”

“At present, it is mostly Chinese components and a few Japanese components like bearings. This has been great for us as our manufacturers are the greatest in the world and the quality has been consistent for the last 10 years. If we can figure out the right way to do, we may do it here too. There is no need for us to import if we can do it locally, especially in such a big market. Here, all the manufacturers make their own engines. When we need to come in, we need to bring in experienced partners. That is quite difficult now,” he said.

CCW has plans to source components out of the country. Scott said the government policies help in making favourable trade deals. Manufacturing in India is very convenient. It is ideal for exports also. The premium motorcycle maker plans to sell about 25,000 units a year in 2 or 3 years and open about 30 showrooms in metropolitan cities and other major towns.

The two-wheeler manufacturer has 2 divisions: Cleveland CycleWerks, the workshop brand where it is highly customisable and more classic; and Cleveland products like FXx and Hooligan R. The company focuses on both the heritage and the future products. With the customer demand for classic bikes the company has invested in it and is developing new products.

About the lifespan of a vehicle, which has come down drastically, Scott said, 10 years ago people used to keep a bike for a longer period. It has changed now. “As a designer, once a motorcycle is designed, it will be moved to the team and they will take care of it. I will move on to the next one. What is new and next keeps pushing me. We are always looking at trends that are happening in the market. There are products in development because we have seen the trend of flipping the bikes in a short-term. This is something we are focused on. In the same time, we also think there are products that customers will keep for a bit longer, especially the classic bikes. But the problem in old bikes and cars is the technology. We, therefore, focus on to keep the technology stable with quality product along with the vintage look.”

He said the Indian customers are more educated. With the customer’s feedback, the company has found that the people here are much less bothered about fuel economy but care for the fun of riding. Based on this understanding, CCW will bring to India its entire product range and also design India-specific products.

“We came to the Indian market with the push rod motor which is an older technology. The reason we went with less powerful motor is, these motors deliver acceleration; the other engines take time to wind up. In India, where congestion is more, we have this. On papers it will be completely different but, if you look at the riding experience this will be better,” Scott said.

“Lightweight is the focus of Ace. A rider does not want heavy bikes to ride past the traffic in India. We have focused on features where the weight of the vehicle can be reduced. For example, the wheel hubs are aluminium with 17-inch front and rear. These are smaller because they spin quicker. In the same way, the chain is also lighter and spins the wheels quicker. The bike uses tubeless tires with inner tubes. This is done to ensure better riding quality with spoke wheels. Even an average mechanic can tune the engine for better results. We will bring overhead cam engines and better technologies to India. But, to start with we want to keep it simple and beautiful,” he added.

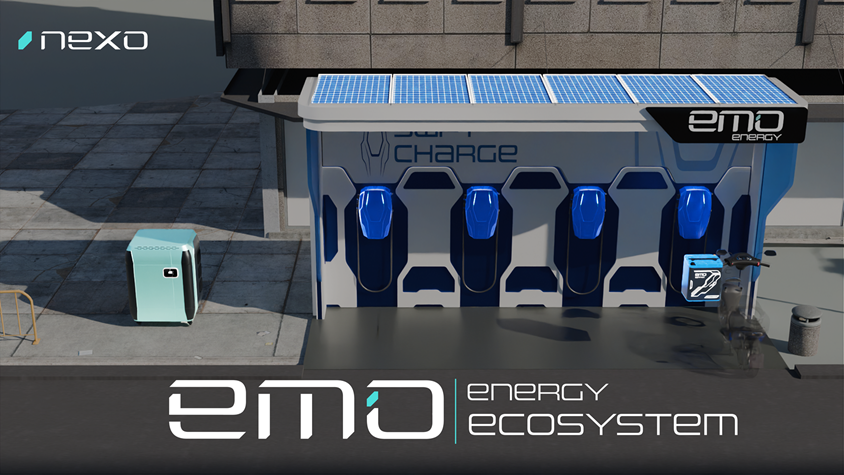

The company has an R&D centre in India. Its design centre is in the US. Scott said there was no plan to set up a design centre here but would continue to build the R&D. CCW also has plans to bring out an electric vehicle. “In India, infrastructure will be a problem. Now, it is extremely difficult to have a plug and to charge your vehicle in the open space. I see there is a push from the government and very less pull from the customers. When this push turns to pull there might be demand and we can enter that segment. As we are a small company, we cannot invest a lot in that now,” Scott said.

Leave a Reply