In a webinar hosted by Messe Frankfurt, 3D printing experts highlighted innovations that are redefining the definites of automotive.

Story by: Deepti Thore

Messe Frankfurt’s recent webinar brought together experts from organisations including Imaginarium, Design Tech and Divide by Zero. Titled ‘3D Printing to redefine efficiency, cost-effectiveness and productivity for Automotive Industry’, the webinar hosted by Automotive Engineering Show, Chennai, drew attention to the innovative trends in the domain known to have brought about a transformation in the automotive industry. Citing the stakeholder measures to avoid stocking excess inventory besides saving on raw material and unutilised tech, the session opened with the panel unanimously agreeing upon the benefits it has to offer. Among key advantages spoken of were hopeful of being able to avoid long development lead times and non-validated designs for production.

3D printing, also known as Additive Manufacturing (AM) involves printing a part layer by layer from a digital design which is in the form of the 3D CAD model. No special tools like a cutting tool or moulds are known to be involved in this process. The part is directly manufactured or printed onto a print bed. Being majorly used for rapid prototyping in the past for the automotive industry, 3D printing, the panellists agreed was fast becoming a prefered choice to create visual models, functional parts, spare parts, jigs and fixtures and in rapid tooling. Stressing on how 3D printing was helping to speed up the design process, improve quality and cut costs, Nishant Shah, Director, Imaginarium (India) Pvt. Ltd. said, “A decade back it used to take months to actually manufacture some parts after designing and to ultimately test the functionality. 3D printing has certainly helped to reduce this time down to a fraction of days and even hours in cases.”

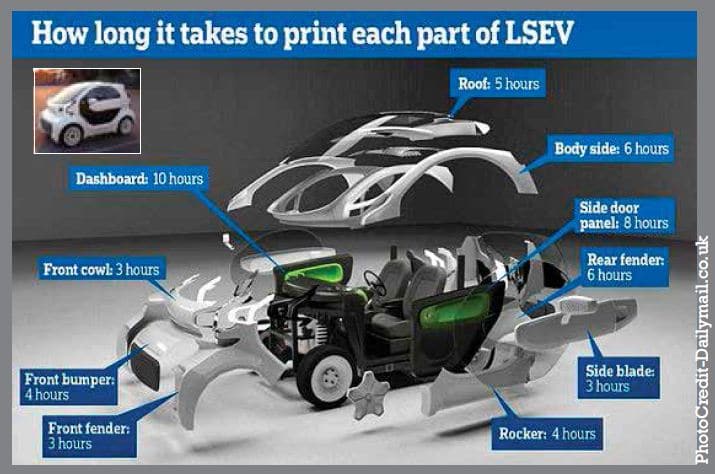

Redefining the EV ecosystem

3D printing is redefining the EV ecosystem. Be it design or manufacturing. Known to require lightweight, highly specialised components in relatively lower quantities compared to conventional internal combustion engine-powered vehicles, EVs have been found to have increased dependence on Fused Deposition Modelling (FDM). The latter is known to enable the construction of three-dimensional objects, prototypes and products through a computer-aided manufacturing process. The melt extrusion method helps deposit filaments of thermal plastics in a specific pattern. A printhead moves along X and Y axis above the build platform.

Redefining light weighting

Light weighting without sacrificing structural strength to attain benefits like enhanced vehicle performance has come a long way. The advent of new materials has helped. A 10 per cent weight shaving could translate to eight to 10 per cent higher fuel economy for instance. Using 3D printing, a study highlighted in the session, drew attention to original equipment manufacturers especially car manufacturers have built the capability to perform alterations at a structural level pertaining to desired components. The redesign of these parts using lattice structures is claimed to involve the use of advanced materials and methodology which in turn has enabled structural elements to deliver equal or greater performance with the use of less material. Besides the use of composites, additive manufacturing has played a significant role, it were said.

Redefining prototyping

Before finalising the design of any automotive part, it is imperative to print several iterations. In a traditional process, it takes weeks or even months. However, with the help of 3D printing, this process can be streamlined and fast-tracked. It provides design alternatives for better visualisation at an extremely low cost other than fast-tracking go-to-market time with the help of tier-1 suppliers. Said to redefine the way cars are being imagined, the material quality and process used in rapid prototyping are claimed to help retain the 3D printed part strength. With the final design only approved after testing all alternatives, it offers a high degree of design flexibility. This facilitates rapid prototyping.

It is a common practice to print production parts to meet the requirements of OEMs, claimed Shah. Citing the example of an OEM in urgent need of bevel gears for an AC unit, he explained how due to the loss of injection moulding tools, the company lost two weeks of precious time. Thousands of bevel gears on vehicles due for roll-out were needed according to Shah. Imaginarium, he added, did quick prototyping and got the parts tested and approved in three days before having them fitted on the vehicle. In another example, he spoke of testing a gear assembly for an OEM. The gearbox is claimed to have been printed, tested and installed in the vehicle. Among other instances, light sized bumpers being fixed after their fitment and aesthetic test, large light parts retrofitted in a vehicle (proto built) after satisfactory checking of fitment and aesthetics were touched upon. The use of transparent material presenting new opportunities in display units was also discussed.

Redefining visualisation

With new car designs flooding the market, it is imperative for designers and stakeholders to validate new designs with visual models. Be it a small tabletop visual model or a full-grown car model. For instance, in one example that came up, Imaginarium was able to 3D print parts for a company wanting to build a supercar for a show in the UK. Most of the parts including the headlamp, black hood, tyres, air vents, wings and the logo were claimed to have been 3D printed. 3D printing it was said goes beyond material or finishes; it can also do transparent or opaque parts for painted classy visual models.

Redefining tooling

Automobile manufacturers, it was said, are heavily dependent on rapid tooling using 3D printers as an alternative to traditional methods of assembly and manufacture for high-quality products. A tooling master model is made. It eliminates long lead times entailed in design change. Citing the world’s first-ever supercar claimed to have been built using 3D printed parts, Shah said, Divergent, saved on costs associated with mould cast or tooling helping the company reduce the capital cost by a 1/50th margin or two per cent.

Redefining spare parts availability

The session drew attention to the immense potential for spare parts availability. Especially in case of redundant models where parts availability is an issue. It is especially useful if a company were to lose the master designs of spares in question and looking to recreate them. Companies are today in a position to provide such spare parts with quick turnaround times. These companies with the help of 3D printing are able to redesign the spare and build a digital inventory in turn. Other companies offer 3D printing machines for customers to print the desired parts on their own.

Redefining mass manufacturing

“In the coming era it is going to be mass customisation over mass manufacturing in the automotive segment,” stressed Shah. Citing Royal Enfield and Bentley, Shah made a case for 3D printing in niche vehicles. Traditional CNC machines, for instance, are good for mass manufacturing and 3D printing it were claimed had the potential to reign supreme in mass customisation. For manufacturing different parts machines takes a lot of time and needs specific tooling and fixturing. 3D printing, it was agreed upon, helped reduce complex parts like tooling and fixturing without the need for a specific reform or component.

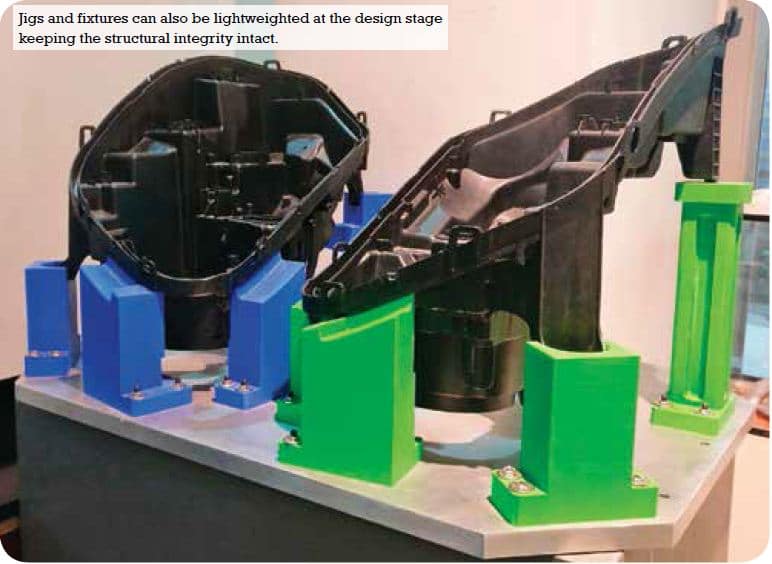

Jigs and Fixtures

Jigs and fixtures is another area of focus for 3D printing. For sheet metal components, jigs and fixtures are mandatory. As per the traditional process metal or casting parts are used in a particular fit and form. 3D printing allows for a high degree of customisation and said to ensure the integrity fo critical area inspections. Jigs and fixtures can also be lightweight at the design stage keeping the structural integrity intact. Weight reductions of upto 65 per cent can be attained. Sparse fill margins of up to 72 per cent, in effect, less material built in to a part, cost savings of 58 per cent as an outcome coupled with led time reductions of 72 per cent are the some of the other OE benchmarks that found a mention.

Ganesh Babu Thiruvengadam. National Manager- Application Engineering at Designtech Systems Pvt. Ltd.

Redefining process and technology

Ganesh Babu Thiruvengadam. National Manager- Application Engineering at Designtech Systems Pvt. Ltd., drew attention to the use of Inkjet or Polyjet technology. Using liquid resins as raw material, fine details are captured in multi-material outputs and end products. The final product with colored or opaque parts, details of the product on the package can be accessed at the push of a button. In FDM, Thermoplastic filament is heated to a semi-liquid state and extruded across computer-controlled tool paths to build parts layer-upon-layer and for Material Jetting, droplets of UV-cured resins are deposited in multiple colors and textures for fine detailed prototypes. These techs were deemed to complement each other. Another application is printing patterns for direct or sand casting in turn used as a pattern for casting aluminium or steel. Used by tier-1 suppliers or OEM, these used to take several weeks previously.

Companies like Divide by Zero are developing 3D printer machines by adopting Internet of Things (IoT). “In additive manufacturing, all you have is a database of design and it can be fired through different printers. We have IoT enabled machines to store these kinds of designs in design libraries and directly fire them through a location of choice with dual access,” explained Swapnil Sansare, Chief Executive Officer at Divide By Zero Technologies. Using 3D printing processes like Stereolithography (SLA) aesthetic testing and production of highly detailed parts and prototypes with a smooth finish can be carried out, he opined. Selective Laser Sintering (SLS) he said was gaining popularity for its ability to produce limited volume, end-use parts.

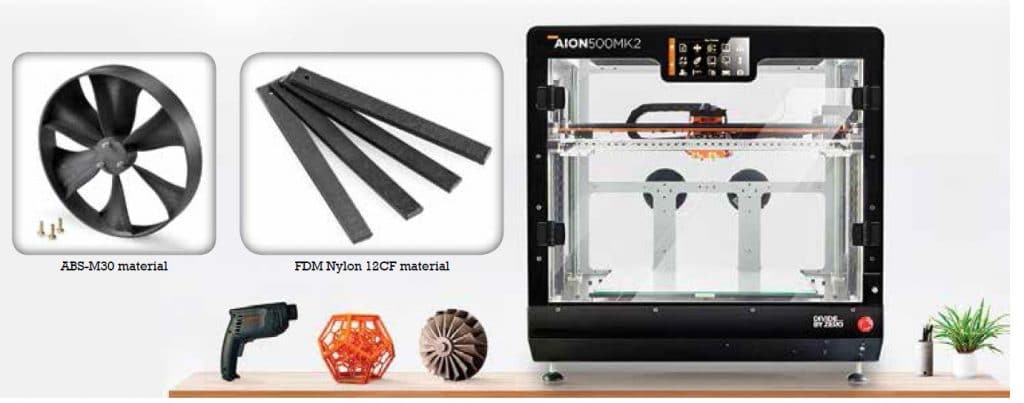

Redefining material choices

3D printing makes use of a range of materials. One such is PA12. Used for sand casting or investment casting as it burns out quickly. For metal 3D printing, alloys such as aluminium, stainless steel, nickel alloys, titanium and even precious metals like gold or silver are popular. Material associated with jigs and fixtures is ABS M30 and ABS ESD7 among others. Resins are ideal for parts that require high finesse and detail. Nylon powder is used extensively in SLS owing to its flexibility. Heat and chemical resistance are an added advantage too. The unsintered powder was said to act as a support to the part manufactured. Polycarbonate was highlighted as the other high tensile strength material. A production-grade thermoplastic, it offers accuracy, durability and stability required to building strong parts capable of withstanding functional testing. High flexural strength and high heat deflection temperature are among its USPs. Nylon 12 is another very versatile material with strong chemical resistance as well as high impact strength and nest z-axis lamination. It was explained as being especially useful for applications like tooling, jigs and fixtures, production parts, snap-fits and friction fit insets. FDM Nylon 12 exhibits 100 to 300 per cent better elongation at break and superior fatigue resistance over any other additive manufacturing technology materials, it was claimed. Price-performance ratio being a distinct advantage. FDM Nylon 12CF is a carbon fibre filled material enabling lightweight tooling. ACI

#DidYouKnow

How AM is creating a pull for EVs?

Trends suggest that Additive manufacturing(AM) or 3D printing is fueling the rise of Electric Vehicles(EVs). With the rising shift towards environment-friendly mode of transportation, demand for EVs is rising. This demand has lead to the need of lighter vehicles and better engine cooling in the automotive segment. Despite recent advances in the reduction of the weight of batteries which power EVs, they continue to be heavier components for the EVs. To improve the vehicles’ efficiency and performance, it is important that the vehicles are lighter in weight hence engineers designing the components of these vehicles are looking for alternatives like AM. AM allows to produce or print such parts using unique geometries thus ensuring reduction of weight of a single part or multiple parts required in an assembly. This reduces weight on the powertrain thus increasing the vehicle range. AM also allows heat exchanging through a 3D printed cooling jacket for the EV’s electric motor and battery which generates a lot of heat during charging. By scanning the car’s motor and battery, the designer develops the design with the help of AM software and then 3D prints the 3D-printed cooling jacket which draws the heat away from the battery and the motor thus enhancing the life of these parts and reducing the wear and tear.

Leave a Reply