In line with the government’s lockdown exit plan, the ACMA manual prescribes a general guideline, preparing for a safe and sustainable restart of the automotive industry.

Story by: Deepti Thore

It is no secret that the automotive industry is process-driven. Safety and Quality practices have always been a top priority. It, therefore, doesn’t surprise that in line with the government’s Covid-19 lockdown exit plan, the Auto Components Manufacturers Association (ACMA) has prepared a manual. The 58-page manual prescribes general guideline to ACMA associates and employees, preparing for a safe and sustainable restart of the industry. Confident of the sector being able to adhere to all prescribed norms of social distancing among other government guidelines, ACMA wants to assure associates and employees of a safe and secure operating environment. According to Vinnie Mehta, Director General at ACMA, the components industry is in preparatory mode, depending upon whether their factories are in green, orange or red zones and if their customer is resuming or not. Stressed Mehta that prior to resuming operations, a host of checks including manufacturing locations undergoing sanitisation procedures need to be done keeping in mind the safety of returning employees.

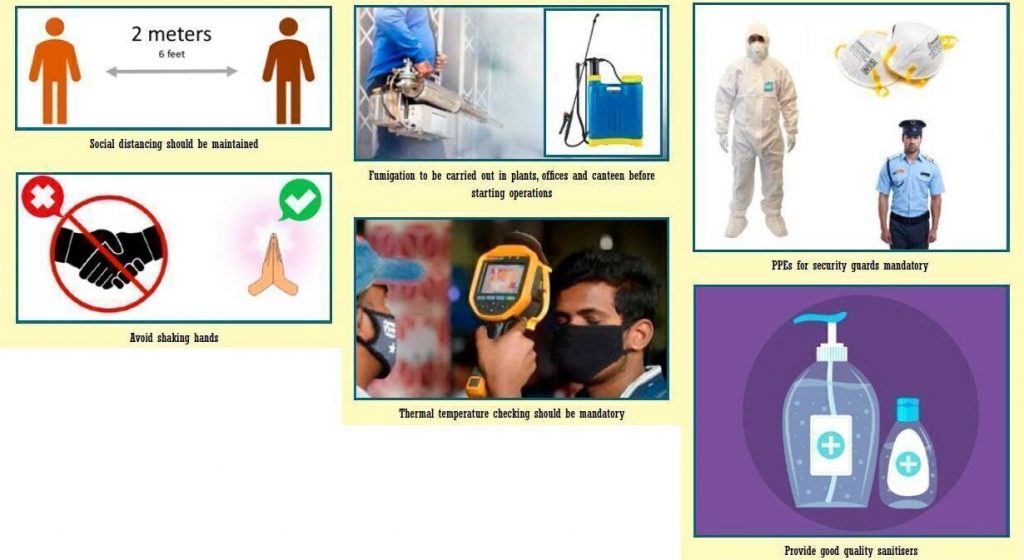

Collating best practices, pooled from ACMA members and other industries, the manual with a foreword from the President includes guidelines from other countries known to have sustained manufacturing operations in spite of practising stringent safety measures. With an aim to explain the precautions needed at each step, the manual pictorially explains necessary preventive steps outlined in an end to end manner. From commuting to the workplace, functioning at the assigned place of work to commuting back home. Recommending download of the Aarogya Setu app. to support the government in this collective fight, the manual stresses the role of the management and the precautions to be taken for employee safety. For instance, the role of the management is highlighted to create an emergency response group. HR teams are asked to regularly communicate and monitor all employees as a standard operating procedure including with associates, contractual employees and their supervisors. Training employees for fumigation and sanitisation methods before starting are strongly advocated too in addition to the emphasis on fumigation of all incoming and outgoing vehicles and materials. In turn, each company is advised to modify the suggested guidelines as deemed appropriate.

Precautionary measures

The guidelines strongly recommend that companies use PPE equipment, chemicals, disinfection tunnels as per the Central and State guidelines. Ensuring availability and use of cloth face masks by all employees features right at the top. The use of PPEs by support staff including security guards, canteen staff and the driver community. Only essential employees are allowed with the rest to be permitted to work from home. The manual further recommends the formulation of strategies to work on a rotational basis by developing multiskills. Thermal temperature checking to be a must for employees ahead of boarding company transport and entering the premise. Hand sanitisation to be made mandatory at all prime locations along with recommendations to ensure social distancing at vulnerable areas including on the shop floor. The manual further recommends regular audit in case of outsourced canteen besides prescribing basic etiquette. In the new normal, the manual further promotes virtual meetings with strict curbs on visitor inflow. The manual recommends creating war rooms with all information and accessibility to be continuously manned with trained personal. It is recommended that lines in the engineering department be redesigned to ensure multi-machine operations using the minimum workforce. Maintenance of industrial wastewater treatment and sewage treatment plants are highly recommended too. It is advised to keep adequate levels of preventive material inventory too. ACI

The guidelines strongly recommend that companies use PPE equipment, chemicals, disinfection tunnels as per the Central and State guidelines. Ensuring availability and use of cloth face masks by all employees features right at the top. The use of PPEs by support staff including security guards, canteen staff and the driver community. Only essential employees are allowed with the rest to be permitted to work from home. The manual further recommends the formulation of strategies to work on a rotational basis by developing multiskills. Thermal temperature checking to be a must for employees ahead of boarding company transport and entering the premise. Hand sanitisation to be made mandatory at all prime locations along with recommendations to ensure social distancing at vulnerable areas including on the shop floor. The manual further recommends regular audit in case of outsourced canteen besides prescribing basic etiquette. In the new normal, the manual further promotes virtual meetings with strict curbs on visitor inflow. The manual recommends creating war rooms with all information and accessibility to be continuously manned with trained personal. It is recommended that lines in the engineering department be redesigned to ensure multi-machine operations using the minimum workforce. Maintenance of industrial wastewater treatment and sewage treatment plants are highly recommended too. It is advised to keep adequate levels of preventive material inventory too. ACI

Leave a Reply