Almost all automotive OEMs worldwide rely on SEG Automotive’s global production network, which delivers high-performance, durable and competitive products with uniform quality standards. This global strength has its foundation in a cross-cultural team of over 8,000 employees in 14 countries in the world’s most important automotive markets. SEG Automotive India with a globally connected Competence Center serves as hub for product innovation and software development, Frank Ahlborn, Vice President, Global Head, Product Management & Marketing of SEG Automotive, and Anil Kumar M R, Managing Director of SEG Automotive India, told Bhargav TS in an exclusive interview. The edited excerpts:

Q: SEG India recently completed its first year of operation in India. How was the journey?

Anil: The journey in India for the last 1 year has been extraordinary. We had double-digit growth, even outperforming the market, both in our India and global operations. We have also acquired new businesses that will secure our future. We were able to position our brand as a good technology leader for climatic protection, particularly for CO2 reduction. With a series of launches we support the OEMs in their journey of transformation. We had the start-stop technology and supported many OEMs and then we introduced high-efficiency generators last year. So overall there has been strong growth. Product innovations continued and we were able to position ourselves strongly.

Q: So how do you assess the Indian market?

Anil: Last year was a great year, of course it started to thin down towards the last quarter. This year we see it’s quite challenging and the first 4 months has not been so great for the Indian automotive sector. There are many reasons like the high ownership cost, high insurance, high inventories and overall price rise. Liquidity crunch is another reason and the lending pressure is becoming higher. With all these there is a situation where the market is de-growing. April was pretty bad almost at -17% on passenger cars. Having said this, if you look into the next half there are lot of optimism in the market because of the political stability coupled with the pre-buying which is still a question mark. But many OEMs are very hopeful that this pre-buying would happen. So the second half may compensate for the first half particularly with the base effect of last year when the last quarter was not so good. So overall the year will end up with a positive growth in India, but what it is a big guess it will be in single digit numbers.

Q: You talked about some of your products, especially on the electrification. Can you just detail SEG India’s business and growth game plan?

Anil: We are a leading player in starters and generators in India. So we want now to penetrate into the electrification market where the growth is. The maximum growth is coming from three-wheelers. So we want to push ourselves into this area and this is dominated by imports. And certainly we would like to take the big chunk of that with our localised product. So that is our key strategy for electrification to penetrate. Having done that we would like to climb up the value chain in the coming years.

Q: When you say localisation, will it be 100% localisation of these products?

Anil: For up to 3 kilowatts, we are having 100% localised solution because we are the rotating machine people of the last century. So we have no issues about improving the technology, bringing in innovation into that and making it 100% local. For more than 3 or 5 kWs we have the BRM today that we import. So we will plan localisation as we go by in the next year as it also depends on volumes.

Q: In India where the market is growing, is it 3 to 5 kW or 1 to 3 kW?

Anil: Currently, it’s up to 3 kW. The e-rickshaw segment is up to 3 kWs and that’s where we are making it 100% local and supporting the FAME also because it requires manufacturers to ramp up otherwise incentives will not be there for the OEMs.

Q: How do you see the growth in India? Is it faster than in any other regions?

Ahlborn: From a long-term perspective India is one of the most interesting markets for us. This is true because we are seeing that the salary per capita is developing a positively and there are certain thresholds and when they are above these thresholds, people start to buy cars and the saturation of the market is still very low. We see a huge potential in the Indian market and there is a huge growth opportunities in the mid and long-term.

Q: India is today among the world’s fastest-growing automotive markets. What is SEG’s near-term and long-term growth forecast for India?

Ahlborn: I would say we are a good and midsize global player in the automotive world and a market leader. We see India as a fast developing market. We see huge potential in China with electric mobility and we are having the right products in our pipeline to enter the North American markets. We also can have product-wise plan and there growth will come from these 12V motors and from the 48V electrification.

Q: How do you define engineering innovation at SEG? Can you cite a few examples that underline the company’s unique capabilities around innovation and engineering?

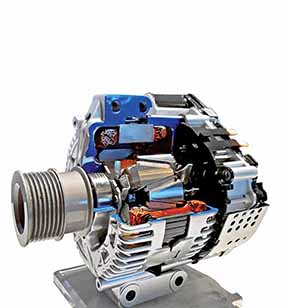

Ahlborn: I think we are very proud of our German heritage of engineering. And as I said, it is not only now this e-machine what we are seeing have that innovation culture. We have the smallest start stop product and if you think about the stress that the starter has to withstand, this was a masterpiece of engineering. This is the smallest production version of start stop system in the world. We have CV generators withstanding more than 1 million km under the roughest conditions. We have high efficiency generators and we were the first to apply high efficiency diode in our generator. So innovation is not something which happened in the last 2 years. This is always going along the whole history. So it’s clearly one of our central points and this is the reason why we have it in our mission and vision statement in the first position.

Q: Generally, no company can work on innovation in isolation, they need OEM partners. How about SEG?

Ahlborn: First statement is also to our journey last year we have over achieved of our order book. So the future is well assured and the customers give us a trust and if they would not give us the trust they would not give us business. So this is a positive sign. This comes from our customer relations here in India and in the world, and they are long lasting. We have made once a calculation that we have above 30 years of long-term relationship with our customers. So this can only happen if you are close together. So our work is clearly directed from technical cooperation with the customers. I give you a nice example, when we started the first 48V project we first started the talks with the customer in 2013-2014. Understanding the requirements we came back with our proposals and it took more than 4 years to go into production. So there is a very strong technical interaction with the OEMs.

Q: So even in the Indian market do you work on a similar fashion? How is the scenario?

Ahlborn: I am really very proud to have Anil and his team here in India. They are doing an excellent job.

Anil: We have extremely strong relations with the Indian OEMs and while we take the global technologies to them, we also listen to them to learn their local needs and that is our strength. The strength that we have and why the Indian OEMs like us so much is because of the power of application. Because it’s just not the product that runs, it is the application that runs and we are extremely strong in applicating and making it custom-built as each vehicle is unique. And the conditions are different and we are the masters of matching these 2 together.

Ahlborn: One thing I would like to add from a global perspective is go to the Indian customers as well to get their feedback on the requirement. So we are reflecting in our global strategy, of course the requirements here from the Indian OEMs are unique and we are strongly connected with them. The products are aligned at a global level for local needs.

Q: What are the major development trends at SEG?

Ahlborn: There are quite a lot of trends that are happening at our end. To highlight, we have successfully entered software development. So we are moving from the purely mechanical and electro mechanical development in the past, as for our latest products we need software. On a global basis we are building our software competencies here in India.

Q: What kinds of products are developed in India for the global applications?

Anil: The huge growth that came in the last 6 to 7 years are from the new base line generators, where we produce almost 2 million and this is driven from the emerging markets. It did not originate from Europe. It was a product that was made for the emerging markets. The project lead was from India and we were able to successfully launch it in the emerging markets and now it is entering Europe. So that’s the strength. So we are both ways very strong.

Ahlborn: There’s also one nice example. Our waterproof starter is coming from India because most competencies have harsh ambient conditions and now we have started exporting to Europe.

Q: You have a Technology Center in India; are you looking at making it as Center of Excellence for any particular product?

Anil: We call it as Competence Center, in fact, that’s what we call our R&D and we are strongly connected globally. The equipment that we have here are similar to the ones that are in Germany and they are globally connected. So tomorrow supposing there is a need in Germany to test certain things and the capacity of the German R&D testing is full we can do it here. So literally we have a shared capacity of Engineers and test equipment across the globe and that is our strength. That is why precisely we call it as GLOCAL, global and local R&D.

Today, the center lies in Germany but we have modules which are made in different parts of the globe and we are actively a part of that. So literally it’s a virtual world. So we do not say that somebody has the competence Center. We are in the virtual competence of the globe and the team is strongly global too. So we have a software guy sitting here as well supporting Germany on different topics.

Q: Technology development in CVs is going much faster than in passenger vehicles. What is your contribution to CVs?

Anil: One of the success factors last year was to bring in a very high efficient generator. So we have the highest in the class of generators and with that efficiency for the CV segment. So, that was one of the innovations that we bought in and lightweighting in the sense having power density more is what we look into the products as well. Co2 is the main driver, so whatever leads in terms of optimisation of the system towards Co2, we are extremely active.

Q: Give us an update on your manufacturing capacities? What kind of products you can manufacture here?

Anil: I am not in a position to share the number but I can tell you that I am the full liner. Right from the three-wheelers up to the heavy duty trucks we have products. We have products for three-wheelers, passenger cars, LCVs and HCVs. The lines are configured in such a way that we have flexibilities in the line to interchange and that is where we can counter the volatility in the market. We can counter because If you have dedicated lines only for CV and passenger cars, then you’re in trouble. So we are flexible and we are well capable of handling the Indian market growth to the capacities that we have. Normally we have 20-25% buffer capacities for any fluctuation. So this is the strategy in which we plan.

Q: How is your exports fairing?

Anil: We are very strong in the exports of starters and generators already. We are the export Hub within SEG and we will continue our dominance for export in the future too.

Q: What is the split between the domestic and the export business?

Anil: It varies anywhere between 35% and 38% of exports.

Q: So finally you’ve been present from three-wheeler to commercial vehicles, any plan to enter the two-wheeler space?

Anil: Thinking about it. It’s on the cards, we are working on it.

Q: So can we expect the two-wheeler products to be on the electrification side?

Anil: Yes your right, it will be towards electrification. There is no point in going with a conventional ICE.

Ahlborn: If you look at our 48V machine up to 7 kW, we are already into two-wheelers in Germany. ACI

Leave a Reply