Chennai headquartered Comstar Automotive Technologies Private Limited has won

the prestigious Ford Global Supplier Excellence Award in ‘Silver’ category for the

supply of starter assemblies. The CEO of the company, Sat Mohan Gupta shares his

views with T Murrali on the journey towards this coveted recognition and the way

forward. Edited excerpts:

Q: Congratulations on getting the Silver Medallion from Ford. Can you take me on the journey towards the recognition?

Q: Congratulations on getting the Silver Medallion from Ford. Can you take me on the journey towards the recognition?

Gupta: It’s a confluence of several efforts right from the shop floor to top management. We have focused on quality and speedi.e. fast delivery. This is what Comstar is built on.

Q: Can you elaborate?

Gupta: We separated from Visteon in 2007 and one of the issues we had after separation was to build customer confidence with Ford and Volvo being the major customers. Comstar’s journey began about 7 years ago and the biggest challenge at that point of time was how a small and independent company that was part of a bigger group (Visteon) could align itself with customers’ expectations. Besides, we had to work on two directions at that time – how we could retain customers and how to improve where we had failed.

Q: How did you go about it?

Gupta: So in 2008, the first steps we had taken were to improve our product development and R&D to catch up with the competition. Customers’ confidence is based on a product which exceeds their expectations on quality, delivery and price; therefore, we started work on these three parameters in 2008-09. In R&D, we decided that we have a definitive edge; we need to move forward on both sides, in the direction where we can support vehicles in the sub-1 litre engines as also for engines that are beyond 2.5 litres for the developed market. So our R&D team started working on addressing these issues while the plant began addressing issues on quality and delivery.

Q: How did your suppliers react on the transformation?

Gupta: The other challenge we faced was to retain some of the suppliers since they had lost confidence in Comstar because we were a small company. We had to retain these suppliers till we built alternative sources to get parts of the same quality. This made us to work on our supplier strategy – to retain some of the good suppliers and evolve a backup plan to tackle some of the issues that came up after separation. It was the culmination of all these efforts that came up with the action plan.

Q: What was the response from your employees?

Gupta: We had issues both at the operators and the professionals level. Professionals like engineers started looking at other opportunities, so we had to fill up those positions and train the people. Also, at the operational level we had to give them the confidence that the company is doing well, looking for new customers, new orders. These were the immediate challenges coupled with the recession in the market in 2008-09. It was short-lived but the impact was lasting. Since we were under transformation the effect was much more. As Ford and Volvo were the major customers we launched a number of initiative despite the recession to touch Rs 500 crore top line by FY 2013 and Rs 100 crore at the EBIDTA level. We achieved our set targets. All these efforts culminated into getting the award

Q: How do you see this milestone change the company in terms of manufacturing and culture of the people?

Gupta: This particular award will bring more challenges, for the expectations of customers like Ford has increased manifold now; After receiving the award the top officials said that they wanted to see us on the podium next year as well. The expectations of top management from our team has also gone up. If we have to be there next year, we have to do better than what we have done today. This award is a total assessment of the supplier on all the parameters including cost, delivery and product development. In the last one and a half years we have launched an initiative that we call 4P – performance, process, productivity, people – which has helped us improve most of the areas of our business especially in speed – how fast a decision is taken and how fast an action is performed; it covers every function in total.

Q: Do you think that there will be a change in the culture of the people?

Gupta: It will be a slow process, but people have definitely started looking at their objectives, the way work has been going on, the things they have been doing. We have Ford as the main customer in North America, Europe and India as also Volvo. We support Ford in China through our licensing agreement partner.

Q: How do other customers perceive you?

Gupta: We supply to Tata Motors, Ashok Leyland – Nissan. It’s more an assurance to the customer that the supplier is doing well. Getting an award always helps especially in proprietary products.

Q: Will this award help in improving your bottom line in the future? Can you negotiate with the customers better in terms of cost?

Gupta: It definitely helps to break the ice with the new customer. As far as bottom line is concerned it is more driven by the competition than the award but at least they will have the confidence that the supplier is good on quality and delivery; that is definitely an advantage.

Q: Is there a downside to this award?

Gupta: I don’t see any downside because it doesn’t mean that we are the single source for Ford. It’s more of an assurance to new and existing customers.

Q: What is the way forward for Comstar?

Gupta: We are working on new technologies that are right now in an advanced stage. Recently we have launched a Change of Mind (CoM) starter motor which the OEMs are using. We are also working on – ABR (Active Bridge Rectification) to enhance the efficiency of alternators. Also we are working on Integral Starters and Generators (ISG) and some technologies for hybrid vehicles.

Q: Can you update on the status of these new developments?

Gupta: ABR and ISG are under testing and validation while CoM has been launched. CoM is the next step on the stop-start system. For example, at a traffic signal when the light turns from red to green you just have to press the accelerator, it will engage and start.

Q: Are these developed jointly with your customers; are they ready to accept these kinds of technologies?

Gupta: Yes, it’s primarily a joint development with the customer. We have the business for CoM, which will be part of the vehicle that is expected to be launched end 2014 or early 2015. The product will be exported to Europe first followed by other

markets.

Q: The distinctive differentiation you have over the competition is narrowing down. Where do you see your control then?

Q: The distinctive differentiation you have over the competition is narrowing down. Where do you see your control then?

Gupta: I would say in addition to quality, delivery and cost have become hygiene factor because if you are not competitive and 100% on time, you don’t get the business. What we offer is speed – not only in terms of time to market new products but also in everything that pertains to customers. For instance, if a customer has an issue, then how fast do you react and respond and how fast do you address those concerns. So for customers, suppliers and our own employees, anything we do in Comstar, w have to see how good we are from the previous action in terms of time.

Q: How do you measure it?

Gupta: We do measure; take for example the response to a quote from a customer. If the turnaround time of sending the quote to the customer was 15 days last year, it is contracted to 12 days this year. After achieving a certain level of operation, it becomes more difficult to improve. However, we are looking at 5% to 7% improvement ever year. We know the issues and expectations with the big companies and how they feel if speed doesn’t happen. Second is that we don’t offer a vanilla product to the customer. What we do is study the application and redesign the motor if required and give him a customised application. We also want to be very competitive on engineering cost – we give cost effective solutions to the customer.

Q: What is the key driving force for you to think on those lines?

Gupta: If you have to distinguish yourself with the big bosses, this is the only way. You have to offer those small, small things to the customer which the competition is not able to give.

Q: When you customise, you lose out on standardisation, which helps you manage cost; there’s always a trade-off. How do you strike a balance?

Gupta: When we offer a customised product, we are addressing two things; one is the cost and the second is the application requirement – the performance. When we go in for customisation we keep the basic structure of the motor the same but change a little bit inside, to give what he needs, like the gear reduction, sizes, magnets or brushes.

Q: The trend is moving towards replacing higher displacement engines with smaller ones; while the space is premium the power requirements are more. In this scenario, where do you see options to add value to the customer?

Gupta: What we have done is to go on both the sides. We have developed a smaller motor and we are constantly working on it to make it more powerful. We look at the different options like brush plates, magnets and work on how to fill more copper into a smaller armature etc; we want to make our smaller motor more powerful.

Q: Do you have a research team?

Gupta: We have a research centre with about 35 people in our campus itself, working on the advanced products. We sometimes use IIT Madras and Vellore Institute of Technology for some of the product development processes.

Q: What is your own outlook since the current slowdown being the longest, which has struck after a short interval of

three and a half years?

Gupta: I think Indian markets will pick-up now with a stable government coming in. Some of the issues which were there till April are slowly fading away; so we are optimistic that the market will soon pick-up. The US is doing good though it may not be a big change as compared to last year but it’s still a stable business with small growth. Europe is still up and down but I don’t think it will be going negative; overall it will be positive. China is growing but not at the same pace.

Q: Can you update on your China plant?

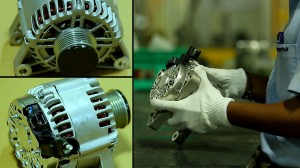

Gupta: Our plant is coming up at Chengdu where Volvo is coming in. The building is ready and we will be supplying to Ford and Volvo; we are working with other OEMs there. We are starting with 1 million starter motors and half a million alternators; In Chennai we have a capacity to make 3.8 million starter motors and over 1 million alternators. Here the capacity is good enough for the next 2-3 years. We utilise around 50% of capacity now.

Q: Are you looking at expanding the manufacturing footprint in India?

Gupta: We have bought lands at Sanand to supply to Ford. We bought the lines from US last year and kept them ready. The plant will add another 1 million units and be operational by 2015-16. We are also working with Volkswagen in Europe, Suzuki in China and Maruti and Hyundai in India. We are working with HeroMotor Corp.

COMe STAR Performer

Comstar Automotive Technologies is the one among 51 global suppliers from 18 countries to get the World Excellence Awards 2013 given by Ford Motor Company. And it is the only company to represent India where it received the award in the Silver category. Instituted about 16 years ago, the ‘World Excellence Award’ recognises the top suppliers to Ford. These awards were designed to identify suppliers who exceed Ford’s expectations and distinguish themselves from their peers by achieving the highest levels of global excellence in quality, cost and delivery performance. Hau Thai-Tang, Group Vice-President, Global Purchasing, Ford Motor Company, said, “These suppliers have demonstrated the highest level of excellence, and we are honored to have them as part of the One Ford team, Congratulations to the 2013 World Excellence Awards winners.”

“Congratulations to all of our supplier partners who have demonstrated a commitment to excellence as we together work to achieve mutual growth,” said Mark Fields, Ford Chief Operating Officer. “Our suppliers are key to the success of our One Ford plan, including our commitment to accelerate our pace of progress and deliver even more of the great products and innovations that will create even more growth and define our company going forward.”

Expressing his happiness the CEO and President of Comstar Automotive Sat Mohan Gupta said, “On behalf of the entire team of Comstar I thank Ford management for honouring us with the 2013 Ford Excellence Award”. To be recognised by Ford and be on the top of more than 1,500 suppliers world-wide, is a great honour and has made the Comstar team proud of its achievement.“This award has only increased our passion to excel, continue to improve on all our deliverables – delivery, quality, cost and technology and we aim to bag Gold in 2014,” the company said. ACI

Leave a Reply