At the maiden edition of the E-mobility India Forum 2021, the stakeholders touched upon the crucial transitional phase to e-mobility. Sumesh Soman shares the roadmap for the industry to realise its vision.

Messe Frankfurt India hosted the maiden edition of the E-Mobility India Forum 2021 powered by the NGV India Summit. Held in New Delhi, the forum witnessed a footfall of 155 delegates who drew attention to the building blocks of India’s electric future in the whole of the energy mix. The topic of discussions spanned from ‘Future of mobility post the conversion to EV’; ‘EV Incentives’; ‘Policy, Challenges and Government support in accelerating electrification’; ‘Opportunities and Challenges for Auto OEMs’; ‘Accelerating EV Component Manufacturing growth through Make in India’; ‘EV Infrastructure and Innovative Business Models’ besides holding interactive knowledge sharing sessions for EV Startups on their approach into the future. The stakeholders deliberated on the country’s impending transition to e-mobility and touched upon the challenges and opportunities en route to realising the end objective of zero emissions. The forum assumes significance as it was held with the backdrop of India committing to meeting its global obligations, most recently at the UN Climate Change Conference (COP 26).

The forum had stakeholders revisit the commitments on reducing the trade deficit by way of cutting oil imports, and tackling air pollution at a time when Particulate Matter (PM 2.5) emission is at its highest in the national capital. Automotive continues to be blamed for the debacle. Sudhendu J Sinha, Advisor, Infrastructure Connectivity and Electric Mobility vertical, NITI Aayog remarked, “The sector is significantly important as the focus of India’s transformative mobility paradigm shifts in terms of shared, connected and electric to meet our global obligations and reduce the negative impact on the cost of importing oil and increasing air pollution in building a self-reliant India.” “The country’s transition to an electric mobility system can save USD 330 billion (Rs.20 lakh crore) by 2030 on avoided oil imports alone,” he opined, setting the tone of the congress. “India’s per capita car ownership is low, with less than 20 vehicles per 1,000 citizens (compared with 800 per 1,000 in the U.S. and 85 per 1,000 in China), though without intervention, this number is likely to increase. This gives an opportunity to shift to EVs earlier and avoid issues of “lock-in” by increase of ICE vehicles,” he added.

Crystal gazing

The forum set the milestones by crystal gazing the future of mobility post India transitions to EVs. N Mohan, Head – EV Charging Infrastructure, Convergence Energy Services Ltd. drew attention to the advancements in the domain of dashboards to begin with. He credited the role of Internet of Things (IoT) and the expected robust network of charging infrastructure for such a change. Expecting that by then, the country would be in a position to eradicate range anxiety among EV owners and potential customers. KC Sharma, Superintendent Engineer (Mechanical), Ministry of Road Transport and Highways expressed how the EV transition was expected to curtail the carbon footprint and would in turn contribute to a cleaner environment. Considering the number of ICE vehicles that are on road, it is important that the EV counterpart makes a significant penetration in order to create a difference.

On the issue of localisation of EVs, Sharma advocated the need to curtail imports. “The indigenous production of batteries and other components for a self-independent EV ecosystem with component level localisation is a must,” he said. He added further that battery swapping would also play a crucial part in addressing range anxiety. Of the opinion that battery swapping was key to increasing the longevity of battery packs, he cited OEM specific chemistries for self-products as a teething issue that needs to be dealt with. “No two vehicles have the same battery compatibility and that technology is yet to be developed. And it will prolong the life span of the vehicle,” he opined. Failing which, he said, it could push the adoption of battery swapping to the advanced stages of the EV transition.

EV Incentives and policies

The government and the OEMs were lauded for a collaborative effort to boost the adoption of EVs among Indian consumers. Schemes like FAME were hailed as the perfect example of the government doing its bit to help the OEMs by way of concessions and incentives developing and manufacturing EVs and their components in India. OEMs on the other hand have introduced lucrative discounts and worked out subscription-based ownership models to lure customers. This was acknowledged as a significant contributor to the traction witnessed in the form of EV sales witnessed during the tough last pandemic marred fiscal. Sudhendu J Sinha, Advisor, Infrastructure Connectivity and Electric Mobility vertical, NITI Aayog, shared how OEMs are ramping up their supply of products on one end of the spectrum with new OEMs joining the race courtesy a low-entry barrier. At the moment, commercial vehicles and passenger vehicles both are witnessing a surge of electrification of vehicles. Every OEM is known to be attempting a portfolio expansion with the addition of an EV in its portfolio.

Sinha reiterated the importance of localisation and hailed NITI Aayog for its focussing on battery packs. He stated, “The targets are not in years but in weeks and months when it comes to EV timelines. And NITI Aayog has studied the success stories of EV manufacturers across the globe.” Crediting the NITI Aayog for initiatives expected to drive sectoral growth, and the efforts to encourage out of the box thinking and innovation at the grass-root level, he expressed confidence of such collaborative efforts together with the industry would prove fruitful in helping consumers overcome their range anxiety and battery life sooner than later.

Opportunities and challenges

As authorities and manufacturers ramp-up to meet the demands of e-mobility, there are tailwinds and headwinds. Speaking on the road ahead, Kaushik Madhavan, VP – Mobility, Frost & Sullivan advocated the need to incentivise the purchase of EVs in order to drive sales as the desired outcome. He drew attention to the battery pack’s second life as being crucial and one that needs to not be overlooked as part of its complete lifecycle. This in turn will help build a strong ecosystem, he said. Balbir Singh Dhillon, Head, Audi India drew attention to the company heading for 100 per cent EV sales by 2026 and turning a complete electric company by 2030 building on the strategy to terminate the use of diesel internal combustion engines going forward. Speaking on the Production Lined Incentive (PLI) scheme, Balbir admitted to the incentives trickling only in the distant future.

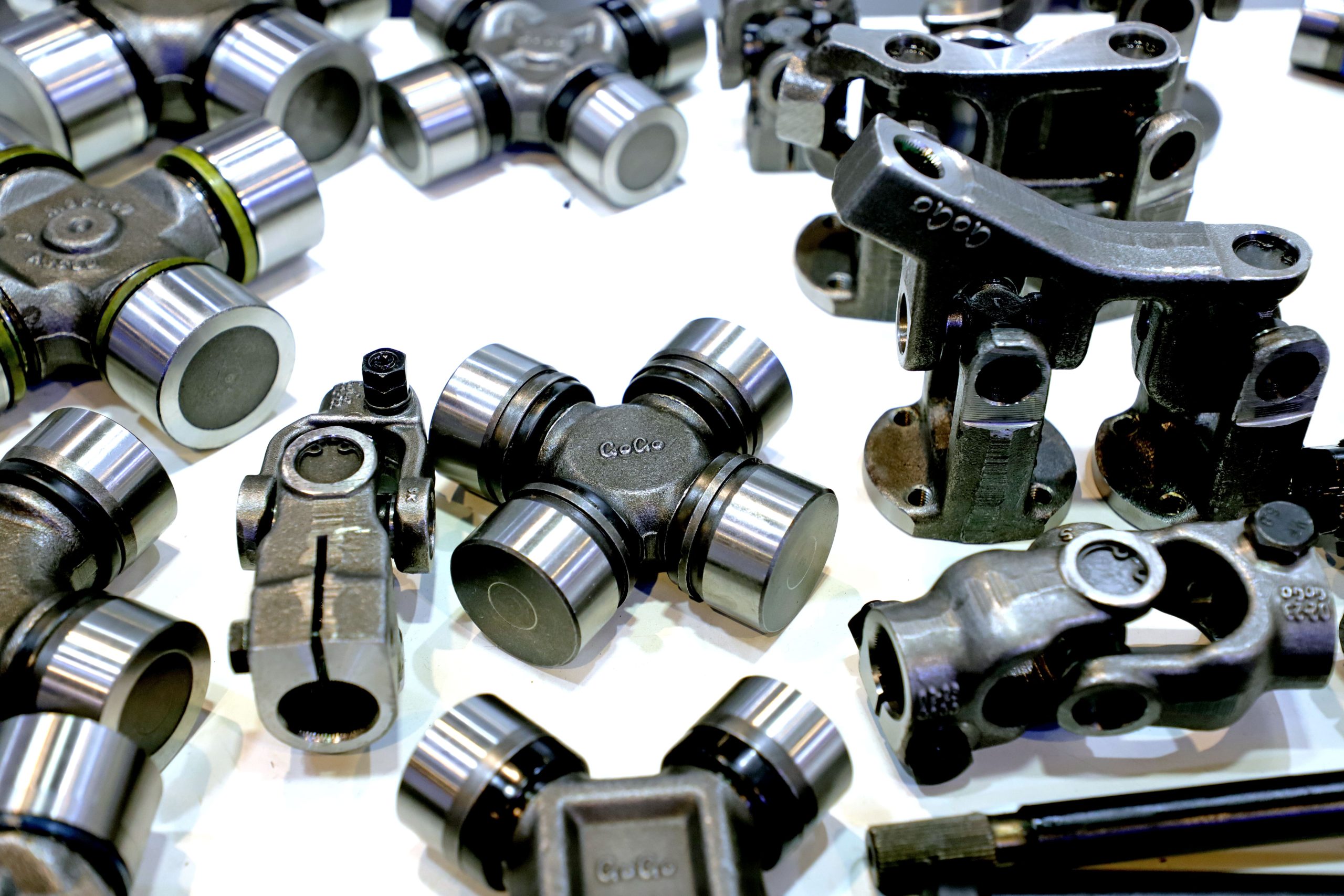

There was a unanimous consensus from the panel on the transition from BSIV to BSVI having made manufacturers heavily invested in order to comply. The panel cited that the pressure mounted owing to the push for electrification soon thereafter and coincided with the headwinds of the pandemic that induced losses. The market has been the most volatile since, all agreed. The role of government in setting up the charging infrastructure was termed crucial and the need to identify strategic locations like stadiums during the off-season to boost the implementation was cited. Guruprasad Mudlapur, Chief Technology Officer at Bosch called India a tough market and opined that a TCO and capacity led growth would pave the way for higher EV volumes. India needs to progress beyond subsidy lead growth, he said. Gajanan Gandhe, Vice President and Country Head at Dana India gave an example of the company aiming for 60-70 per cent localisation levels pertaining to the motors. “The low cost products will eventually phase out, and only premium products will have longevity coaxing consumers to pay a premium for such a product,” he mentioned.

He gave an example of Dana India exporting half a billion worth of goods from India to make a case for local manufacturing in the country. On segments expected to do well, he made a strong case for PCB manufacturing. Atul Arya, Head-Energy System Division,Panasonic India made a crucial comment when he cited the surge in demand for EVs putting pressure on raw materials. “It is a challenge even for cobalt, copper and other raw materials. There is a huge demand and companies are trying to push batteries that use less of these raw materials,” he shared.

Accelerating EV component manufacturing

Guruprasad cited how electronic components had increased in both ICE and EVs alike. This has also increased complexity, he admitted. If these components are imported, then the production cost is bound to go up which in turn will reduce the demand of the vehicle, he explained. He urged OEMs to focus on EVs especially the batteries, the very pivot of the vehicle. “Localised batteries will be of great help in controlling the product costs. The PLI scheme and the Make in India programme must be leveraged to accelerate EV component manufacturing in the country,” he stated. Atul pointed at the importance of investing in batteries to realise a low TCO. “Investing in quality components is important for the growth of EVs. The research environment must be pushed further,” he exclaimed.

EV Infra and Innovative business models

Calling it a classic example of the chicken and egg story, the panel set out to deliberate on the infrastructural push and the role of innovative business models in the last leg of the forum. The stakeholders agreed that the way forward on infrastructure of EVs needs to be one where the OEMs and energy suppliers progress regardless of the government support. Policies and incentives must be used as a supplementary push and not the decider of the industry’s fate. Sudhendu made a crucial point when he said that for every 100 units of electricity spent to move an EV, 37 units were renewable. “The energy needed to push a vehicle a kilometre forward is 40 per cent less as compared to ICE. So EV is the future, there is no choice here,” he beamed. Sunjay Kapur, Chairman, SONA Comstar Ltd and President, Automotive Component Manufacturers Association (ACMA) opined that the supply chain, infrastructure, customer outreach and communication requires a complete overhaul with the focus now shifting towards EVs and green mobility. “India stands at the cusp of revolution that can completely alter the mobility scenario in the country. Looking at this grand opportunity, the E-Mobility India Forum provided an apt platform to discuss the way forward for the EV industry and to help bring various stakeholders together to create an ecosystem for the future of EVs in the country,” he concluded. The event, in hindsight, succeeded in bringing the industry up close and personal at a time of a crossover with such key developments set to drive the future.

Leave a Reply