The electronically-driven fan drive promises to optimise fuel-economy while ensuring compliance with increasingly stringent emission norms. This development is the latest symbol of BorgWarner’s multifaceted presence in India.

The electronically-driven fan drive promises to optimise fuel-economy while ensuring compliance with increasingly stringent emission norms. This development is the latest symbol of BorgWarner’s multifaceted presence in India.

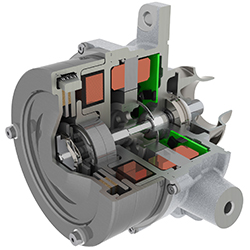

BorgWarner Cooling Systems India, the wholly-owned subsidiary of BorgWarner Thermal Systems based in the US, is currently working on about ten projects for different OEMs in India to deploy the Visctronic – its next generation viscous fan drives. In the current phase of trials, the drives are being tested with 180-240HP engines to pave the way for market introduction in 2014. ‘We have the capability to make Visctronic drives for engines falling above and below this range too,’ states V D Umashanker, Managing Director, BorgWarner Cooling Systems India. The OEMs are responding well to Visctronic, given that BorgWarner claims that it offers three percent improvement in fuelefficiency and five-six percent power consumption benefit, relative to viscous fan drives. BorgWarner Cooling Systems has been manufacturing viscous fan drives, which controls the speed of the radiator fan based on the thermal characteristics of the engine in order to optimise fuel-efficiency and emissions compliance. In a conventional viscous fan drive, the bi-metal coil senses the engine’s temperature and accordingly controls the valve that regulates the flow of the silicon liquid, which acts as the media. This mechanism controls the engagement and disengagement of the clutch in order to allow the fan to control temperature.

The electronically managed or directlyactuated visctronic fan drive provides improved fuel economy through lower disengaged speeds and optimum fan load management during cooling periods. The product’s precise airflow management allows for tighter control of engine temperature, leading to a potential reduction in exhaust emissions. Moreover, not only does the Visctronic help reduce fan noise, but it also frees up engine power for other tasks through smoother speed transitions. It also extends the life of the fan drive belt, which is critical to engine performance. In the Visctronic drive, the inner clutch disc is driven by the input shaft which is connected to the crankshaft or a remote-bearing bracket. The clutch’s input speed is equal to the engine speed or increased by a transmission required activation is calculated by a specifically calibrated software module in the ECU. Since Visctronic is electronicallycontrolled, vehicle/engine manufacturers have a lot of flexibility in terms of where they want to measure the temperature and how the air flow is to be varied or modified. Thanks to a digital approach, measurements are possible from zero to the maximum stipulated RPM of a given engine. Thermal shocks may thus be avoided since uniform gradients of temperature are possible. While the improved temperature control help extend engine and component life too, the self-contained unit is maintenancefree. The system incorporates input/output (I/O) ports to receive and send signals from the ECU. ‘Our capability lies in marrying the electronics of visctronic fan drives with the ECU, to optimise efficiency,’ Umashanker says. Generally, BorgWarner

The electronically managed or directlyactuated visctronic fan drive provides improved fuel economy through lower disengaged speeds and optimum fan load management during cooling periods. The product’s precise airflow management allows for tighter control of engine temperature, leading to a potential reduction in exhaust emissions. Moreover, not only does the Visctronic help reduce fan noise, but it also frees up engine power for other tasks through smoother speed transitions. It also extends the life of the fan drive belt, which is critical to engine performance. In the Visctronic drive, the inner clutch disc is driven by the input shaft which is connected to the crankshaft or a remote-bearing bracket. The clutch’s input speed is equal to the engine speed or increased by a transmission required activation is calculated by a specifically calibrated software module in the ECU. Since Visctronic is electronicallycontrolled, vehicle/engine manufacturers have a lot of flexibility in terms of where they want to measure the temperature and how the air flow is to be varied or modified. Thanks to a digital approach, measurements are possible from zero to the maximum stipulated RPM of a given engine. Thermal shocks may thus be avoided since uniform gradients of temperature are possible. While the improved temperature control help extend engine and component life too, the self-contained unit is maintenancefree. The system incorporates input/output (I/O) ports to receive and send signals from the ECU. ‘Our capability lies in marrying the electronics of visctronic fan drives with the ECU, to optimise efficiency,’ Umashanker says. Generally, BorgWarner  Cooling Systems works with OEMs who in turn associate with the ECU manufacturer. Should units require modifications and additional I/Os, the company works directly with ECU manufacturers. The Visctronic incorporates inherent flexibility in that it, it allows OEMs the option to deploy up to 600mm fans should there be space. This move can help to control the engine’s temperature even at reduced speeds, further improving fuel economy. In the light of all these advantages, Umashanker claims that ‘the incremental costs of the Visctronic may be amortised within a run of less than two lakh km.’ Visctronic fans may be better than viscous fans in most respects, but the negative for the latter is that they cannot be retrofitted like the former. ‘The electronics in the Visctronic has to be mated with that of the ECU. This aspect makes the Visctronic unsuited as a retrofit solution,’ informs Umashanker.

Cooling Systems works with OEMs who in turn associate with the ECU manufacturer. Should units require modifications and additional I/Os, the company works directly with ECU manufacturers. The Visctronic incorporates inherent flexibility in that it, it allows OEMs the option to deploy up to 600mm fans should there be space. This move can help to control the engine’s temperature even at reduced speeds, further improving fuel economy. In the light of all these advantages, Umashanker claims that ‘the incremental costs of the Visctronic may be amortised within a run of less than two lakh km.’ Visctronic fans may be better than viscous fans in most respects, but the negative for the latter is that they cannot be retrofitted like the former. ‘The electronics in the Visctronic has to be mated with that of the ECU. This aspect makes the Visctronic unsuited as a retrofit solution,’ informs Umashanker.

Strong presence

Strong presence

Globally, BorgWarner Thermal Systems holds a 30-40 percent share in the combined market for conventional and electronically-controlled viscous drives. Competitor Behr also stacks up with a similar market share. A handful of Japanese and Korean manufacturers are also in the fray. In India BorgWarner is 10-15 percent ahead in terms of market share over its nearest competitor. The company has benefitted from a first mover advantage. Incepted in 2001 BorgWarner Cooling Systems has since 2004 been operating from rented locations close to Chennai. With the India foray bearing fruit, the company acquired a 6.35-acre plot in Sriperumbudur. It has since invested about Rs 30 crore for a built up area of over 60,000 sq ft. Currently BorgWarner Cooling Systems makes viscous fan drives and fans. However, BorgWarner has yet to start the manufacture of the Visctronic in India. The new generation fan drive’s technology demands a different line, which the company can only set up once volumes picks up. At present, BorgWarner only caters to the requirements of OEMs like Ashok Leyland, M&M, Volvo India, VECV and Tata Motors. Soon, Umashanker informs, the company will begin supplies for a global platform of Volvo Trucks that will be applicated in three countries including India. In any case, the company has also begun exporting viscous drives to BorgWarner Thermal Systems’ plant in Thailand. While these next developments gather steam, the company has added a new range of viscous drives with integrated ring fans that seek to optimise the cost-value proposition for the Indian market.  The ring connecting the blades at the periphery helps in containing noise that is generated at high speeds. It also helps to enhance the airflow to the engine in the interest of better efficiency. At some point in the future, BorgWarner Cooling Systems is looking to introduce ‘dual mode coolant pump’ and ‘heavy-duty controlled coolant pump’ into India. The variable speed pump is driven by high-efficiency maintenance free brush-less DC motor. For peak cooling requirements the mechanical clutch actuates the pulley drive. The combo helps cool the engine during engine shutdown too, which helps in improved performance, in case the vehicle has to move within a short interval. The pump allows for additional average fuel savings of one percent. The innovative design of the heavy duty controlled coolant pump allows OEMs to precisely control the impeller’s speed to produce the desired coolant flow rate. The system significantly lowers average pump speed as well as energy consumption, eventually reducing energy loses which translate into fuel savings. Due to the fully modulating speed range of the impeller, the engagement is soft, thereby minimising friction further. This pump too aids in the realisation of additional average fuel savings of one percent. At the moment, the two pumps are being introduced in Europe and the US to ensure compliance with Euro VI regulations. In recent times, BorgWarner Cooling Systems has been collaborating with Modine Thermal Systems Private Limited (a subsidiary of US-based Modine Manufacturing company) to offer an integrated solution to customers. The global companies work together without the involvement of equity holdings. Under the arrangement, Modine’s heat exchangers and BorgWarner’s cooling modules are offered to customers as part of an integrated package. Either company has the opportunity to be the tier-1 supplier for an OEM contract with the other being a supporting entity.

The ring connecting the blades at the periphery helps in containing noise that is generated at high speeds. It also helps to enhance the airflow to the engine in the interest of better efficiency. At some point in the future, BorgWarner Cooling Systems is looking to introduce ‘dual mode coolant pump’ and ‘heavy-duty controlled coolant pump’ into India. The variable speed pump is driven by high-efficiency maintenance free brush-less DC motor. For peak cooling requirements the mechanical clutch actuates the pulley drive. The combo helps cool the engine during engine shutdown too, which helps in improved performance, in case the vehicle has to move within a short interval. The pump allows for additional average fuel savings of one percent. The innovative design of the heavy duty controlled coolant pump allows OEMs to precisely control the impeller’s speed to produce the desired coolant flow rate. The system significantly lowers average pump speed as well as energy consumption, eventually reducing energy loses which translate into fuel savings. Due to the fully modulating speed range of the impeller, the engagement is soft, thereby minimising friction further. This pump too aids in the realisation of additional average fuel savings of one percent. At the moment, the two pumps are being introduced in Europe and the US to ensure compliance with Euro VI regulations. In recent times, BorgWarner Cooling Systems has been collaborating with Modine Thermal Systems Private Limited (a subsidiary of US-based Modine Manufacturing company) to offer an integrated solution to customers. The global companies work together without the involvement of equity holdings. Under the arrangement, Modine’s heat exchangers and BorgWarner’s cooling modules are offered to customers as part of an integrated package. Either company has the opportunity to be the tier-1 supplier for an OEM contract with the other being a supporting entity.

Specialised businesses

Specialised businesses

BorgWarner is represented though business entities, other than BorgWarner Cooling Systems in India. For starters, BorgWarner MorseTEC India Pvt. Ltd., manufactures solutions like engine timing systems, silent chains, roller and bushing chains, tensioners, sprockets, arms and guides. This subsidiary has managed to make rapid inroads in the Indian market and has amassed a veritable client base, which includes Hyundai, Maruti Suzuki, Mahindra & Mahindra, Hero Honda, Honda Motors, Suzuki, Yamaha and TVS Motors. The company is presently engaged in researching friction reduction, in petrol and diesel timing systems for passengers vehicles. The group is also present in the emission space, with BorgWarner Emissions Systems, which manufactures products that for air management and emissions control in passenger cars, light trucks and commercial vehicles. At present, it manufactures exhaust gas recirculation (EGR) coolers, tubes, valves and modules in India. The company, is set to increase its manufacturing capacity, and provide sales, design, test and validation capabilities, to domestic and international automakers. ‘We are investing in both, local production and testing, so that customers may be provided with system-based solutions, tailored to their needs,’ says Brady Ericson, President and General Manager, BorgWarner Emissions Systems. He adds, that the new facility would enable the company to strengthen its share in the EGR coolers market, while meeting product demands in the passenger and commercial diesel vehicle segment. BorgWarner Emissions Systems is optimistic about its EGR coolers business in India, which it expects to grow at an annual growth rate of 35 percent, within five years. BorgWarner has forged a number of joint ventures (JV) which include, Divgi-Warner a JV between BorgWarner TorqTransfer Systems, USA and Divgi-Metalwares, India. The JV primarily offers torque distribution and management systems, and produces a range of transfer cases, automatic locking hubs and AWD couplings. In order to cash in on the demand for instant start systems and pressure sensor glow plugs, BERU Diesel Start Systems Private Ltd. It is a JV between BorgWarner BERU Systems and the Jayant Group. The JV currently supplies glow plugs, intake air heaters, controllers, flame start systems and ignition coils to the likes of Tata Motors, Ford, Fiat, Mahindra & Mahindra and Ashok Leyland. While a JV with Turbo Energy, offers advanced turbocharger technology for passenger and commercial vehicles. Thus, with a veritable array of products set to take engine performance to dizzying heights. BorgWarner certainly has made it big in the Indian auto component market.

Story & Photography: T Murrali

Leave a Reply