Text: Bhushan Mhapralkar

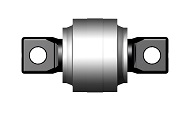

In what may look like a simple assembly, a torque rod in a truck, tractor or a trailer has a multi-functional role to play. It controls drive-line angles of the vehicle, restrains rotation of the axle housing while accelerating and braking, locates the axle and maintains alignment and absorbs leaning and cornering forces. Two types of torque are found often: with rubber bushings in fixed and adjustable lengths and with full ball joint end designs. The endeavour to manufacture torque rods was undertaken by Pune-based Varsha Forgings Limited (VFL) in 2007 in an effort to become a Tier-1 supplier. Moving up the value chain in response to the demand from clients for machined parts rather than just forged parts, VFL formed a chassis and suspension division in 2007 with plants located at Aurangabad and Pune. It was about forward integration. The company had added precision machining of forged parts as per customer needs, and as a value addition.

“We were supplying forged and machined parts to MAN Trucks India. MAN Trucks India wanted to reduce the cost of the torque rod for their truck and tipper application by localising the complex assembly. We had invested towards machining of forged parts. The machining activity gave us the confidence to set up a new facility in 2007 to add full assembly of torque rods and V-links line. We added a 200-tonne press, which could be used for hot crimping with tube heating furnace and created new infrastructure to assemble torque rods by outsourcing ball pin rubber,” said Jitendra Munot, Chairman, VFL.

“We were supplying forged and machined parts to MAN Trucks India. MAN Trucks India wanted to reduce the cost of the torque rod for their truck and tipper application by localising the complex assembly. We had invested towards machining of forged parts. The machining activity gave us the confidence to set up a new facility in 2007 to add full assembly of torque rods and V-links line. We added a 200-tonne press, which could be used for hot crimping with tube heating furnace and created new infrastructure to assemble torque rods by outsourcing ball pin rubber,” said Jitendra Munot, Chairman, VFL.

Apart from the infrastructure needed to manufacture torque rods and V-links, VFL installed test rigs for dynamic load. It also installed a universal testing machine for pull-out and push-out tests. Torque rods and V-links came to complement other VFL products like sector shaft, pitman arm, differential case and housing, lower arms, crown wheel and pinion, flanges, steering arms and end covers, which find use in commercial vehicles. Some of these parts find use in the manufacture of steering gear aggregates, which are supplied to commercial vehicle manufacturers by a Tier 1 supplier. “The earlier version of the torque rod was with an eye end welded to the tube. Crimping was subsequently introduced in place of welding. To impart adequate strength with reference to the actual vehicle load condition and field trail experience, we developed a seven-groove design”, Munot mentioned. “We received patent from the Government of India in 2012-13 for it,” he added. VFL also received an award from SME Chamber of India, Mumbai, in the technological innovation category.

VFL’s expertise lies in the development of profile and intricate shape forgings. “VFL follows continuous improvement – kaizen as its vision. We aspire to offer products to clients as a system supplier”, explained Munot. To ensure that it is able to address the demanding needs of clients, VFL has invested in Bricks Cad, Delcam, Catia and Unigrphics as modern design tools. The company has also invested in test rigs for optimum design, which satisfies OEM’s specific load conditions of pull out, buckling test and hit-to-obstacle test. The ball joint assembly used in the torque rod is also tested for various load conditions, for axial stiffness and radial direction. A conical cardanic stiffness test is also carried out on the ball joint. Apart from MAN Trucks India, VFL caters to Daimler India, Ashok Leyland, Mahindra Trucks and Buses, Taco Hendrickson, and coach builders like Corona Bus, Veera Vahan Udyog and JBM Group. VFL also caters to international clients like Daimler, Paccar, Scania, and Tata Daewoo. “Major OEMs used to procure torque rods from Germany, China and USA, which made it very expensive. By localising the torque rod, we help them to lower the cost. We also enhance the quality and ensure smooth delivery. We manufacture 1,20,000 torque rods and 60,000 V-links per annum,” Munot mentioned.

VFL’s expertise lies in the development of profile and intricate shape forgings. “VFL follows continuous improvement – kaizen as its vision. We aspire to offer products to clients as a system supplier”, explained Munot. To ensure that it is able to address the demanding needs of clients, VFL has invested in Bricks Cad, Delcam, Catia and Unigrphics as modern design tools. The company has also invested in test rigs for optimum design, which satisfies OEM’s specific load conditions of pull out, buckling test and hit-to-obstacle test. The ball joint assembly used in the torque rod is also tested for various load conditions, for axial stiffness and radial direction. A conical cardanic stiffness test is also carried out on the ball joint. Apart from MAN Trucks India, VFL caters to Daimler India, Ashok Leyland, Mahindra Trucks and Buses, Taco Hendrickson, and coach builders like Corona Bus, Veera Vahan Udyog and JBM Group. VFL also caters to international clients like Daimler, Paccar, Scania, and Tata Daewoo. “Major OEMs used to procure torque rods from Germany, China and USA, which made it very expensive. By localising the torque rod, we help them to lower the cost. We also enhance the quality and ensure smooth delivery. We manufacture 1,20,000 torque rods and 60,000 V-links per annum,” Munot mentioned.

The slow down over the last two years did not spare VFL. Sentiments are however turning positive, and a recovery in the CV sector is expected sooner than later. Especially on the back of the resurgence of activity in areas like infrastructure and mining. “We are optimistic and ready with short- and long-term initiatives to address the increase in volumes,” said Munot. VFL’s standalone turnover in FY2013-14 was Rs 30 crore (Rs 4.5 crore was on account of torque rods). In the current fiscal, the company is expecting a turnover of Rs 40 crore, a growth of 33%. Apart from existing clients, VFL is also looking forward to serve new clients like Foton, Scania and Isuzu, which have recently entered the Indian commercial vehicle sector. In an effort to offer the best and the most appropriate solutions, VFL has developed an infrastructure to manufacture adjustable torque rods. The company is also working towards adopting new technologies and using new materials like polyurethane bushes.

To offer a one-stop solution to commercial vehicle and tractor OEMs, VFL recently inked a joint venture with Korea Central Corporation (S. Korea). The new company, KCTR Varsha Automotive, is based at Pune, and manufactures steering linkages and suspension parts like drag link, tie rod and ball joint assemblies. “We are a customer-driven company. We have always worked closely with our clients, and will continue to work with them for the development of new products,” concluded Munot.

Mr. Subhash Kulkarni

Offers automobile components, automotive Components manufacturer, automotive machined components, precision metal washers and spacer, manufacturer, India