The simulation tool from Ansys, Inc looks promising. Deepti Thore checks how it helps engineers break the design and innovation boundaries.

Completing 50 years of relentless innovation, Ansys, Inc. is singularly focused on giving engineers the clarity and confidence to simulate their way towards transformational innovation. The company through its simulation tool is empowering engineers to break the design and innovation boundaries. It is providing them with the ability to understand how a product works or it doesn’t in the real world. It’s simulation tool has not only become a superpower which enables faster time-to-market but it also lowers manufacturing costs, improves quality and decreases risk of failure. “In vehicle engineering, Ansys provides the most accurate simulation capabilities tailored for the detailed engineering needs of vehicle technology,” informed Rafiq Somani, Area Vice President – India and South Asia Pacific, Ansys, Inc., these solutions enable the simulation of vehicle systems comprehensively with fully integrated structural, crash, fluids, thermal, electromagnetic, electronics, optics, software and systems simulation solutions.

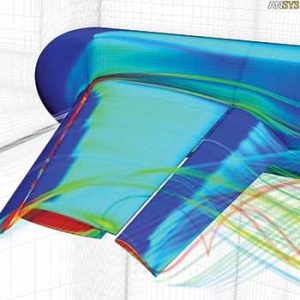

The evolution of simulation in India and globally is driven by urbanisation, growth in population, regulations, environmental concerns, pandemic, and an increased demand for sustainability. Hence, the automotive industry is witnessing a paradigm shift in adopting multiple technologies in its value chain. The next-generation simulation tool helps the industry to innovate faster from the component to the system of systems. Prevalent in all segments and at all stages of vehicle design, from aerodynamics to battery management system testing, simulation enables rapid, risk-free testing and development. Depending upon the type of tool or product, Ansys’ comprehensive suite of software places demands on computing and hardware resources that can vary significantly from one model to another. Factors that determines the optimal computing hardware include model physics, model size, model complexity and how fast results are needed. Depending on the customer requirement Ansys experts provide recommendations about the right set-up, confirmed Rafiq.

The evolution of simulation in India and globally is driven by urbanisation, growth in population, regulations, environmental concerns, pandemic, and an increased demand for sustainability. Hence, the automotive industry is witnessing a paradigm shift in adopting multiple technologies in its value chain. The next-generation simulation tool helps the industry to innovate faster from the component to the system of systems. Prevalent in all segments and at all stages of vehicle design, from aerodynamics to battery management system testing, simulation enables rapid, risk-free testing and development. Depending upon the type of tool or product, Ansys’ comprehensive suite of software places demands on computing and hardware resources that can vary significantly from one model to another. Factors that determines the optimal computing hardware include model physics, model size, model complexity and how fast results are needed. Depending on the customer requirement Ansys experts provide recommendations about the right set-up, confirmed Rafiq.

The need for the tool

The automotive industry today demands substantially higher levels of quality, reliability and durability while being cost-effective, and competitive. Significant challenges of various types confront the automotive industry today including the stringent emission regulations, strict crash worthiness or occupant safety legislation, fast changing customer preferences and ever-increasing demand for better fuel economy, improved vehicle performance and reliability. Simulation plays a key role in electric vehicles, vehicle engineering, ADAS and Autonomous Vehicles and Safety Engineering. They enable rapid electric and hybrid vehicle innovation for both component and system levels in EVs. Some key applications of simulation include batteries and battery management systems, fuel cells, power electronics, electric motors, and the integrated electrified powertrain system. “In ADAS and Autonomous Vehicles, safety by design and safety by validation are crucial factors,” exclaimed Rafiq. “We support customers from high-fidelity physics-based sensor modelling to ISO26262 and AUTOSAR compliant embedded software development which enables engineers to meet industry required safety standards at a dramatically lower cost and achieve a much faster development cycle,” he added further. The company’s physics-based automotive digital twin solution spans critical vehicle engineering disciplines including exteriors, interiors, chassis, powertrain and electrical.

The automotive industry today demands substantially higher levels of quality, reliability and durability while being cost-effective, and competitive. Significant challenges of various types confront the automotive industry today including the stringent emission regulations, strict crash worthiness or occupant safety legislation, fast changing customer preferences and ever-increasing demand for better fuel economy, improved vehicle performance and reliability. Simulation plays a key role in electric vehicles, vehicle engineering, ADAS and Autonomous Vehicles and Safety Engineering. They enable rapid electric and hybrid vehicle innovation for both component and system levels in EVs. Some key applications of simulation include batteries and battery management systems, fuel cells, power electronics, electric motors, and the integrated electrified powertrain system. “In ADAS and Autonomous Vehicles, safety by design and safety by validation are crucial factors,” exclaimed Rafiq. “We support customers from high-fidelity physics-based sensor modelling to ISO26262 and AUTOSAR compliant embedded software development which enables engineers to meet industry required safety standards at a dramatically lower cost and achieve a much faster development cycle,” he added further. The company’s physics-based automotive digital twin solution spans critical vehicle engineering disciplines including exteriors, interiors, chassis, powertrain and electrical.

Electronic Circuit Simulation

According to Rafiq, Integrated Circuit (IC) components are part of nearly every major electronics application. Many emerging market segments require reliable operations for 10 to 15 years, even in severe environments. Most IC reliability assessments, however, only focus on meeting the demand of consumer applications that last an average of five years. Robust predictions of IC life in modern, high-reliability applications require a different approach. With a foundation in reliability and semiconductor physics, the Ansys team uses simulation, testing, and teardown analysis to define IC failure risk in specific applications and identify reliability drivers. Whether you are trying to reduce component integration risk in a new application or solve IC reliability challenges in a severe environment, Ansys experts have the experience and resources to help, asserted Rafiq.

Traditional simulation and modelling techniques for ICs require extensive design, manufacturing, and test information that is not typically available to IC integrators and product designers. The company’s approach to IC reliability assessment helps designers mitigate reliability concerns early in the development process, using information about technology node and functional blocks to predict susceptibility to hot carrier injection, negative bias temperature instability, time-dependent dielectric breakdown, and other common IC failure mechanisms. This approach allows company to simulate the reliability of ICs in application-specific environments, without access to detailed IC design information. Ansys has centres in Pune, Noida and Bengaluru. Its R&D operations in India are the second largest for the company, outside the US. The company is also working on some new technologies for enterprise solutions and cloud technologies, informed Rafiq.

Competitive edge

Macro trends, such as the development of autonomous vehicles and the drive toward environment friendly electric vehicles, influence the increased demand for simulation in the automotive sector. Simulation is today used by automotive designers to test and develop new ideas in a multitude of ways from the body of the automotive and scan through engine design, battery system testing, and finally, advanced driver assistance features and autonomous vehicles. Witnessing adoption of simulation beyond product development today, the company uses it in ideation stages, material selection, manufacturing, production as well as maintenance and end of life of the products. In order to maintain competitive edge and bring products to the market faster, it is crucial to get it right the first time and that is where engineering simulation helps designers. Simulation driven product development will pave way for localisation of design and equipment manufacture. The company is helping its customers in the localising the development and manufacturing. Ansys has also tied up with many of the academia which have their own incubation centres and a lot of in-house start-up companies, allowing them to take the help of the faculties there. With India’s manpower and the competencies, it is possible to think global. “With extraordinarily complex systems of modern vehicles, simulation is the future of transportation and mobility,” Rafiq concluded.

Leave a Reply