Garware Polyester introduces a next-generation self-healing paint protection film for automotive applications in India.

Story by:

Deven Lad

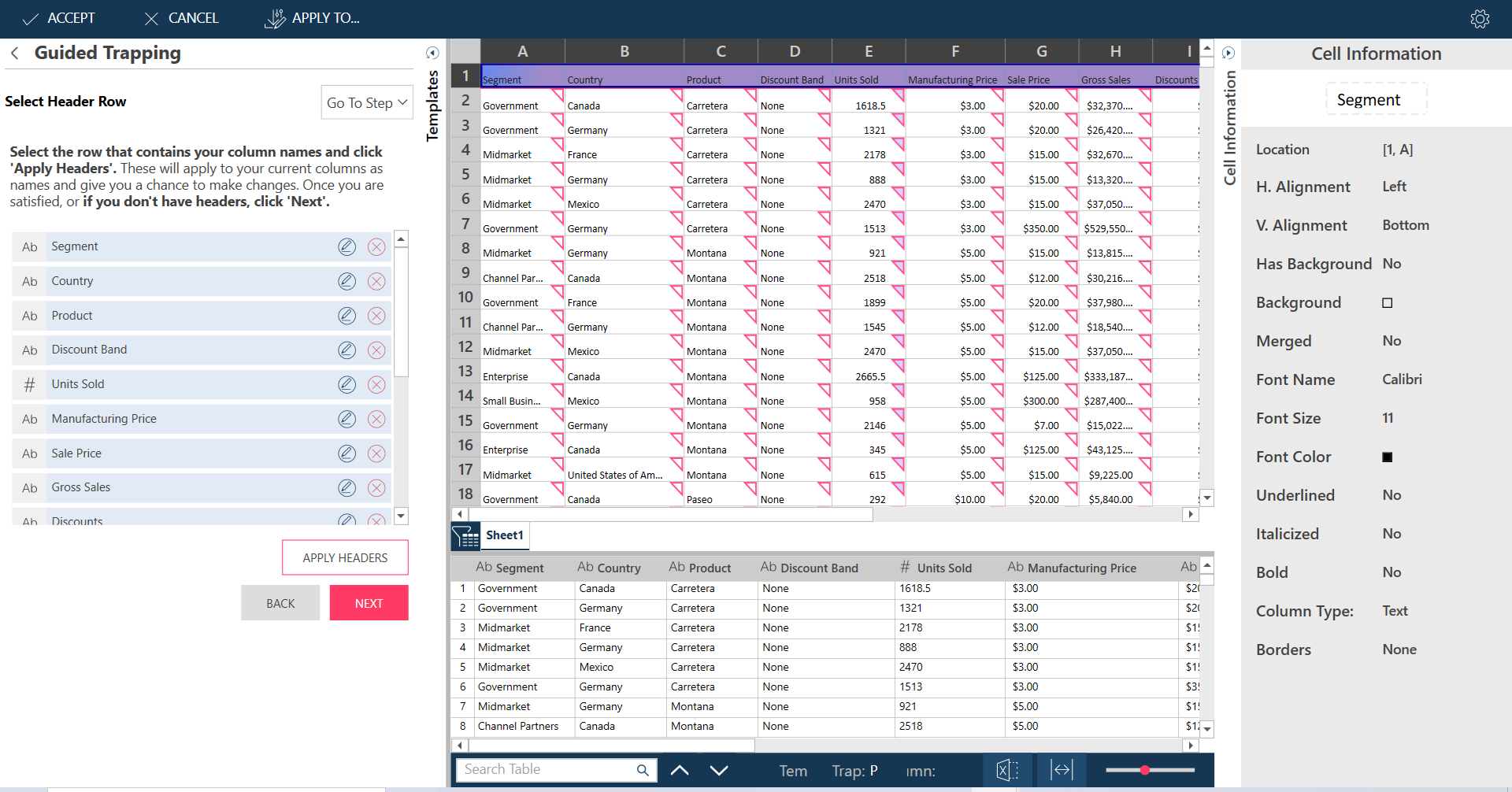

Offering the highest level of impact resistance, Garware Polyester Pvt. Ltd., the flagship company of the Garware Group, has introduced a self-healing paint protection film in India. Manufactured in India using a specially formulated Thermoplastic Polyurethane film (TPU) and the company’s in-house technology, the next-generation self-healing film is claimed to be suitable especially for Indian weather and road conditions. S. Krishnan, Director -Sales, Garware Polyester Ltd. said, “The latest version of the paint protection film is yet another innovative product, which provides an unparalleled high-gloss finish and impact protection for maximum durability.” Aimed at passenger vehicles, the film is claimed to offer protection from scratches and dents. Ensuring protection from damages made by road debris and rocks, the TPU film is manufactured by coating specially formulated acrylic-based adhesive. The self-healing TPU film is laminated with Matte silicone coated release liner. The protection film is then top layer of the self-healing coating. Offering a self-healing property from minor to medium scratches, superior optical clarity and high gloss finish, the TPU film gives the vehicle on which it sits as a coat a premium finish. Known to be water repellent and durable, the film is easy to install on the curved surfaces of the vehicle. The film also claims to offer a superior solvent resistance. Along with anti-yellowing and stain resistance, the film protects from the bird droppings, and insects besides from exposure to salt air.

The most advanced vehicle paint protection film in the market as of current, according to Krishnan, can be easily installed as well as removed without damaging the paint finish thus helping to retain the vehicle’s resale value. Coming from a company that manufactures polyester films for a variety of industrial applications and solar window films for automobile and architectural applications, the TPU film is manufactured in a state-of-the-art, ISO-9001: 2008 certified facility that also produces just about everything that goes into Garware’s window films, from the base petrochemical intermediate right down to the finished products. Capable of being used as full-body wrap, as a hood wrap, as a bumper wrap, on the rocker panel, on the quarter panel, on painted side mirrors, on door handle cavity, on door edges, for the leading hood edge, and the wheel arches, the TPU film is installed with an inbuilt gel as part of the product. The gel is said to facilitate proper and easy installation.

Care must be taken to ensure that the installation environment’s temperature is within a range of 20 degree Celsius to 32 degree Celsius. The film costs Rs.675 per sq. ft. Installation in cars smaller than a Toyota Fortuner, for instance, is expected to require less than 200 sq. ft for a full wrap. It translates to a total cost of Rs.1.35 lakh. Customers can also opt for a Do It Yourself (DIY) kit to wrap the car themselves. In addition, the company also offers a panel-specific film for customers who do not require a full wrap. The self-healing film takes about two to three hours to heal a small or medium-sized scratch, claimed Krishnan. The film also blocks UV rays and adds more gloss to the paint besides maintaining the life of the existing coat of paint. The self-healing PPF comes with a three-year warranty.

The paint protection market is valued at approximately Rs.3,500 to Rs.4,000 crore according to reports. Said to be dominated by companies like 3M and Lumar with a good chunk of import from China, Garware is looking at the export potential of the ‘Made in India’ film to countries like the US, Russia, the Middle East, South Africa. It is estimated to earn the company an additional revenue of Rs.300 crore over a period of two years with this strategy. Garware Polyster’s total revenue is pegged at Rs.950 crore.

Before finding use in the automobile space,Paint Protection Films (PPF) or clear bra as it’s known globally has been around since the 1950s. Traced back as a protection mechanism for war vehicles, the film is known to have been developed for the Vietnam war. Made of thermoplastic urethane, the film was used as a coat on military transportation equipment. It is till date known for its application on helicopter rotor blades. It is the defence use that is said to have paved the way for the film to be accepted as a lightweight coating with no adverse effects on transport operations. The biggest advantage was that its protective layer helped to avoid varied surfaces from damage. It was in the 1980s when PPF made an entry in the motor sport with racing teams known to have used the film to protect the front end of their race cars from track rubber, debris, and close contact with cars in races. ACI

Self Healing Paint Protection Film

The self-healing film is manufactured by coating a specially formulated acrylic-based adhesive (thickness of 1.18 mil or 0.00118 inches), and a self-healing coated TPU (six mil or 0.006 inch). It is laminated with matte silicone coated release liner (thickness of three mil or 0.006 inches), and a protection film ( thickness of two mil or 0.002 inches) placed on top of the self-healing coating ( thickness of 0.78 mil or 0.00078 inches). The key USPs of the self-healing PPF is the automated self-healing property in case of the minor to the medium category of scratches, optical clarity and high gloss finish, water repellent property and durable stain resistance, anti-yellowing, solvent resistance besides the resistance to maintenance pains like bird droppings. Customer also has to take care of the film after installing like cleaning up dirt and dust on the film regularly, using microfiber, avoid using abrasive like power and clay-type cleaners, degreasers or rough sponges and paper towels. The company also advises not using high-pressure water hoses or putting a lot of pressure on the film while cleaning. “We are planning to train people who will be using this, in few months we expect more than 500 experts who know how to install it. We are introducing this product in the domestic and international market where our presence is already there and they will learn about this product quickly,” said S. Krishnan, Director -Sales, Garware Polyester Ltd.

Interview Box : In conversation with S. Krishnan, Director (Sales), Garware Polyester Ltd.

Q. From polyester films to the self-healing paint protection film how has the product development journey of the company been?

A. As the pioneer of polyester film manufacturing, we have been in this business for long, in fact, we were the first company to have launched a polyester film. Now we are introducing Paint Protection Film (PPF). We have also gone through the phase of introducing window films which are very popular and sold globally in about 80 countries. The paint protection film is an extension of that product in the automotive space. It is used for protecting the paint coat on a car. The journey has been long I would say and one that has helped us with valuable learnings in the manufacturing space.

Q. Give us a snapshot of the company’s growth pattern over the last eight quarters? Have you been impacted with a slowdown in the auto sector and economy overall?

A. Our growth over the last eight quarters has been fairly good. Our profitability has been extremely high in this period. I can’t comment on our last quarter (Q2-FY2020) as the results are yet to be declared. Our profit was Rs.120 crore in the last Financial Year (FY2019). Compared to the profit three years ago, we were at about Rs.29 crore. So from a profit of Rs.29 crore to Rs.120 crore, the growth has been phenomenal.

Q. As an early mover with the first of its kind plant in South East Asia, have you been able to build on that advantage?

A. We are diversified, unlike other companies who only continued to make polyester films. We went on to manufacture window films and moved on to PPF. Going forward you will see us manufacture several other products.

Q. Self-healing PPF is not a new technology per se. What are the product properties in the next generation of PPF? Does it address issues like film yellowing or bubbling and nasty residues?

A. Along with our product, we are also selling an installation gel, developed in-house. This installation gel helps in terms of proper installation of the product, therefore, there is no question of bubbling and other effects in the installation process. In addition to that self-healing property which quickly heals, there is no other form of treatment that is required by the film to function as intended.

Q. Does the PPF need an additional layer of coating for daily wash and care routine?

A. It does not require any further coating. The only thing required is regular soap solution and usual precaution that you take in terms of cleaning or maintenance that needs to be taken care of.

Q. How does a Garware PPF differentiate itself from competing companies both in the domestic and the global market?

A. Our product is unique given that it has all the advantages and all the requirements a PPF needs to offer. A similar product from global players offers at the most two or three benefits. Either its self-healing or scratch resistance or it is hydrophobic. In comparison, we provide all of that in one product. In addition to this, our product is also priced competitively.

Q. Do you have a reseller business model with partner vendors in the supply chain?

A. We have distributors in the global market, our largest market, for instance, is in the United States. We also have distributors and retailers in India. We have trained them on all the applications of our products to ensure a robust network and ease of availability for our customers.

Q. Is the PPF an after-sales product purely?

A. It is an after-sale product as well as for OEM equipment in some countries. In our oldest plant, we plan to sell it to the OEM where it can be used to protect some of the vulnerable parts of an automobile.

Q. With buyers looking at price-competitive products over genuine care products, how confident are you of creating a pull?

A. This product has not just been developed under certain ideal lab conditions, but also It has been subjected to tests under all sorts of weather conditions and patterns, especially for a country like ours. So we manufacture not only what’s best suited for our country but test the products by way of simulated conditions of other countries, covering both cold and hot weather cycles. In fact, some of our big customers have already started ordering from the middle east where the temperatures are recorded upwards of 48 degrees Celsius.

Q. How Green is the product?

A. It is environment-friendly.

The normal life of this product is five years.

Q. Tell us about the R&D capability, manufacturing capability, and dealership network of the company?

A. Garware has always prioritised R&D. Ever since the inception, one of the main objectives has been to introduce new products in the market. PPF is one of those products that bring to the fore our capabilities. The dealership network has penetrated from tier-1 cities to tier-2 regions where we have an entire chain of retailers and distributors.

Q. What are the export aspirations and which markets do you already cater to?

A. We expect to sell in 80 countries across the globe with the same markets doubling up as potential markets for PPF. With most of them already using PPF from fortune 500 companies, our aim is also to break into the top 500.

Q. What are your growth areas and challenge areas over short to medium and medium to long term?

A. PPF is going to give us access to a large market across the globe. With the company looking to enter 80 countries, we believe the big growth challenges will be to train human resources across demographies in these different countries and ensuring that the products suit a wide array of application type and sustain in different weather conditions. While we have tested the products in different conditions, its time to test it on the ground and gather learnings for the future.

Leave a Reply