Of late we are seeing a massive trend in the electrification of vehicles, however, the reports say despite that ICE will continue to dominate the market in the Asia Pacific, including India, write Krishna Gowdaman A (Application Engineering Specialist, India, Automotive Aftermarket Division, 3M) and Suparno Hazra (Application Engineering Manager, South APAC, Automotive Aftermarket Division, 3M)

In the report shared by Mordor Intelligence, on ‘ICE Vehicle Market Share And Trends’, it is estimated that the share will grow by CAGR 3.9 per cent between 2019-29. Despite the government’s plan of 30 per cent EV penetration by 2030, there will be a larger population of ICE vehicles coexisting in the market. Hence, it is important to understand how we can maintain the health of those engines for better performance, lesser pollution, and overall higher efficiency.

Krishna Gowdaman

By large, automobiles are regulated by various aspects in countries, some of the key elements are emissions and safety. The emission regulations evolved and became more and more stringent. Automobile OEMs have made significant efforts to adopt these stringent regulations by including sophisticated technologies and these technologies are not entirely maintenance-free. These technologies demand regular services to sustain its fitness and in turn, deliver the overall performance of the vehicle.

If we try to generalise, four critical components

can affect the vehicle performance: The fuel system, the air intake system, the powertrain, and the exhaust system. The health of those systems ensures the maximum output from our vehicles.

Driving practice, traffic conditions, maintenance patterns and fuel quality lead to a buildup of deposits onto critical components like the throttle plate and body, fuel injectors, intake valves, combustion chambers and exhaust systems. The buildup of deposits affects engine performance, causing poor fuel economy, loss of horsepower, rough idling and hesitations when stepping on the acceleration pedal. These problems are often first noticed during cold start, or after driving shorter distances or driving at lower speeds. It’s vital to remove/ reduce deposits like gum, resin, and carbon aside from regular maintenance practices. Vehicle maintenance is a vast topic though; predictive maintenance needs to be exercised to keep the vehicle up and running at its best. In the vehicle routine maintenance schedule, there are various areas to check and upkeep like the power train, brake, lubrication, fuel, cooling system etc. We will be discussing on what are the key aspects to be looked upon to maintain the powertrain, fuel and exhaust system.

Ø The Fuel System

A fuel system consists of key components like fuel pumps, tanks, filters, and injectors. Except for filters, many times rest of the components are not checked or serviced until there is a need for it or a drop in performance of the vehicle and it’s related to the fuel system. Although these are designed to function well for many services. However, various factors like fuel adulteration, traffic and road conditions, and driving habits lead to gum, varnish and carbon deposits onto injectors. This may compromise spray volume, particle size and pattern of fuel getting sprayed in the combustion chamber hence leading to alteration in Air-Fuel ratio (AFR). When the AFR is altered there can be loss of power and emits excessive harmful exhaust gas. This can affect the Exhaust Gas Recirculation (EGR) value as well. So, it’s a vicious cycle and hence these deposits need to be cleaned or else there are chances that the injectors will malfunction and may need a replacement in the run. One of the good practices is to use periodically Fuel system cleaners to service them. Fuel system cleaners are small investments to better/ restore the engine performance. Professional Fuel system cleaner is focused process of running the vehicle on the cleaner itself, while the engine runs on the cleaner, the cleaner cleans the fuel system, however, if it can be done pro actively at certain intervals, it will help restore the engine performance periodically. Even if the engine is already affected the professional fuel system cleaning can be done as a reactive solution as well.

The other variety of fuel injector cleaners is those which can be added to the fuel tanks with the

recommended dosage. These solutions can be added to the fuel tank between services. These solutions help ensure the smooth operation of the injectors like new by cleaning the Internal Diameter Injector Deposits (IDID) periodically. Fuel and powertrain work hand in hand to deliver the desired torque and power of the engine. It’s important to maintain the powertrain system as well.

Ø The Air intake system

Combustion engines, rely on a mixture of fuel (such as petrol or diesel) and air to generate power. During the combustion process, the fuel is ignited, and the heat produced causes it to react with the oxygen in the air. This reaction releases energy in the form of heat, which is then converted into mechanical energy to power the engine. Without a sufficient supply of air, the combustion process cannot occur efficiently. The oxygen in the air is necessary for the fuel to burn completely, ensuring optimal combustion and power output. Insufficient air supply can lead to incomplete combustion, resulting in reduced engine performance, increased fuel consumption, and higher emissions.

To ensure proper combustion, combustion engines are designed with air intake systems that regulate the amount of air entering the engine. This allows for the precise control of the air-fuel mixture, optimising combustion efficiency and overall engine performance.

In the air intake system, throttle assembly is a critical part of the air intake system. Dirt, residue, and gummy, varnishy deposits can adversely affect the performance of the throttle plate and its seating area. There are chances of leakage between the throttle plate and the throttle body due to these unwanted deposits. It can restrict the airflow, and thereby lead to incomplete fuel decomposition and finally deterioration of the engine’s peak operating performance.

While selecting the cleaners, it is important to select a cleaner formulation that not only cleans but also is safe for coated throttle plates and should not cause any damage to the components. The cleaner should clean the throttle bodies and plate assemblies and it should lubricate to help restore maximum operating efficiency, without damaging the components.

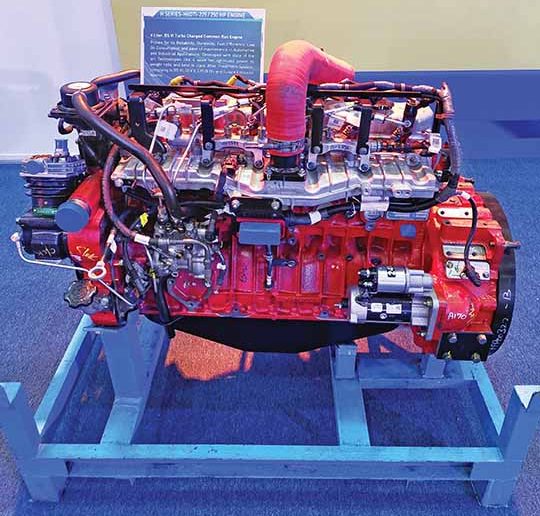

Ø The powertrain

Powertrain plays a vital role in converting the chemical to mechanical energy. The powertrain components work together to provide the necessary power and torque to move the vehicle efficiently and smoothly. The main components of the powertrain are the engine, transmission, driveshaft and differential. The engine is the heart which directly affects the performance of the car. The fuel that gets into the combustion chamber of the engine must burn the way it is meant to be to give the rated torque, and power with the expected fuel economy & emissions in limits. This is hindered when there is a deposit of carbon in the combustion chamber, piston, cylinder head, especially valve and value seating areas.

Carbon deposits eventually may not allow the valve to sit properly on to seating area and can lead to a combustion leak. This may also lead to compromised performance and increased exhaust gas emissions. This also leads to compromised mileage as incomplete combustion leads to higher consumption of the fuel to make up for the inefficiency. Hence a proper periodic decarbonisation will complement the fuel system cleaning at frequency.

Ø The exhaust system

The exhaust system has various critical mechanisms for the engine to perform. It consists of an EGR valve, Catalytic convertor, gasoline particulate filter, and Diesel Particulate Filter (DPF) respectively. These mechanisms are important to reduce harmful exhaust gas emissions. Carbon and sludge get deposited onto these mechanisms over some time leading to clogging on these mechanisms and reducing the efficiency. Catalytic converters turn carbon monoxide, hydrocarbons, nitrogen oxides, and other exhaust engine emissions into less harmful compounds, so they don’t hurt you or the environment. When clogged it will not convert these harmful gases into less harmful compounds, which leads to the emission of harmful compounds to the environment. To clean the clog, it is important to use appropriate cleaners and restore the efficiency for the overall

performance of the engine.

Maintaining the health of the engine is not only critical for the optimal performance of the car but also from the sustainability point of view. An optimally performing engine ensures a reduction in smoke and unburned particles and helps to minimize pollution. Traditionally all these professional Fuel Cleaners fall under the Dangerous Goods category, as they are mostly aerosols and contain low flash point solvents to ensure ready combustion. However, that means these products are highly flammable and we need to be careful of their storage and transportation. One of the recent trends in the market is to opt for alternate solutions which perform the same as fuel cleaners but are in the non-dangerous goods category, which means they are non-aerosols and high flash point solvents. They need special formulations and special application systems, which some companies are already bringing to the market. In a few countries, the government is also promoting this making the whole ecosystem more sustainable. ACI

—————————————–

The views expressed by the authors are their own and do not necessarily reflect the views of ACI Magazine.

Box

Selecting The Right Professional Solution

The selection of the right professional solution stands critical for the maintenance of the aforesaid system. One should consider the below important aspects before selecting solutions to perform the job.

The cleaning solution should be performing yet compatible with all the minutes of soft components like rubber seals, gaskets, various coatings etc.,

The authenticity that it cleans the aforesaid contaminations from the assemblies in discussion is substantiated by clear scientific data.

Solutions which contain less harmful solvents and sustainable solutions.

Prevention is better than cure, great to have preventive solutions at a certain frequency rather than allowing the engine to deteriorate and fix it.

End

Leave a Reply