In an upfront interaction, Jayakumar G, Group President India, Valeo India Pvt. Ltd. speaks to Ashish Bhatia on the changing customer perception driving changes in the automotive industry.

Q. How are you contributing to the reduction of CO2 emissions and the development of safer driving? Which products in the portfolio are contributing to this vision?

A. 94 per cent of our turnover comes from technologies reducing CO2 emissions and improving safety. 10 years ago, Valeo committed to making CO2 emissions reduction its growth driver. Thanks to more than Euro 10 billion that we have invested in electrification, we have become the world leader in the field. Both in low and high voltage. Nearly 60 per cent of our sales now stem from technologies that contribute to reducing CO2 emissions. As a pioneer and world number one in vehicle electrification, Valeo boasts the widest technologies portfolio to support this revolution. Technologies that cover all segments and all use cases, from affordable hybrid solutions to the most powerful systems.

Valeo develops electrification technologies and efficient thermal management systems for EVs but also works on weight reduction and efficiency improvements to reduce CO2 emissions. Valeo is committed to achieving carbon neutrality by 2050 and reach 45 per cent of its objective by 2030. In concrete terms, this means that by 2030 we will have nearly halved our carbon footprint across our entire value chain, be it emissions from our plants, our manufacturing processes and our energy supply, or the emissions from our suppliers and the end-use of our technologies.

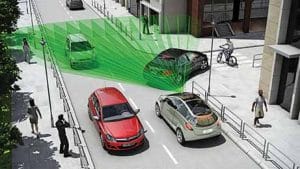

Improving safety on the roads is certainly the other major challenge of mobility. For a long time, Valeo has developed technologies able to help the driver to perceive its environment. Our driving assistance technologies currently equip one in four new vehicles worldwide. We were pioneers in this field, with the invention, 30 years ago, of the first ultrasonic sensor for parking assistance. Since then we have developed the broadest sensor portfolio on the market including ultrasonic sensors, radars, cameras and the one and only LiDAR on the automotive market in series production and fitted in series production vehicles.

Another major lever for improving safety on the roads is visibility systems, that encompass lighting and or wiping. We are the world leader in this field too. One figure sums up the challenge: 72 per cent of fatal road accidents take place at night when visibility is most impaired. The headlights we currently sell today allow you to drive with full headlights on in all circumstances, without dazzling the drivers coming in front. The smart lighting systems will go soon far beyond simply improving visibility. They will completely exceed their original functional scope to provide more safety, assistance and driving comfort, drawing the curves of the road, announcing the next bend, reproducing road signs, or even drawing a protected passage on the road to invite the pedestrian to cross.

Q. Elaborate on the development of the advanced range of facings for clutches (including moulded facings), tractor brakes and friction washers?

A. Increasing emission norms, better roads, growth in infrastructure and increased drive comfort demands by the end customers constantly challenge the development of facings. Increasing emission norms, reduction in packaging space and higher engine speeds in passenger and commercial vehicle applications demand high burst, stable friction at elevated temperatures and low-density clutch facings. For tractor dry disc brakes, high friction facings support the driver to brake with a lesser pedal effort, in turn, reducing driver fatigue and thereby increasing on-field productivity. These are some of the recent developments in the facings for clutches and brakes.

Q. What is the G5 clean technology and have there been any recent iterations made to it that you can share?

A. In the friction facings, Generation 5 (G5) technology water is used as a solvent. No other organic solvents are used. This helps in CO2 reduction in the manufacturing process. This is a good example of how Valeo’s commitment to environmental protection is now embodied in the extensive product and process design expertise used to eliminate dangerous materials from production processes. The Chennai plant is the second facility in the world to implement this process. Valeo implemented this process at least 10 years ahead of the relevant global regulations. In performance terms, occupants of vehicles adopting the G5 clutch will experience enhanced levels of driving comfort when changing gear due to the suppression of engine vibrations and the extremely smooth, judder-free, clutch action.

Q. Staying on brakes, how have you optimised associated emissions for different duty cycles?

A. In brakes, we operate in the tractor segment only. Stable high friction even at elevated temperatures reduces the stopping distance. This increases the driver’s confidence on brakes and avoids partial braking during the drive, which in turn saves fuel and hence reduces emissions. When the confidence on brakes is higher, tractor drivers tend to avoid half-clutching, which in turn reduces fuel consumption.

Q. How are you prioritising the go-to-market strategy which means catering to different technologies (manual to automatic/single to dual-clutch) and vehicle segments on a regional basis across your key target markets? Exports are known to have significantly contributed to the overall revenue.

A. Valeo has development and manufacturing sites distributed across countries. This is based on regional demands and the availability of competent manpower. In India, the Automotive market is dominated by manual transmission – across different formats of vehicles – three-wheelers, passenger cars, SUV, MUV, micro to large trucks, buses and farm equipment. Hence, our Chennai facility leads dry facings for manual transmissions and supplies facings to Valeo, LuK, ZF, Eaton, Exedy and other domestic clutch makers. We also export friction facings to the global market from Chennai. Exports have grown significantly in 2020 for us despite the covid pandemic, which has contributed to the revenues for Indian operations. The development of facings for wet applications happens in Europe.

Q. How are you leveraging the Chennai R&D centre as a global hub with learnings and resultant efficiencies introduced over the pandemic-marred fiscal?

A. Valeo’s Chennai R&D centre caters not just to local developmental needs, but also the needs of Valeo’s global sites. Our Chennai R&D centre provides engineering support across varying domains – Mechanical, Simulations, Electronics, Software & Vision systems. Our R&D centre in Chennai was operationally supporting both local and global engineering development despite the pandemic induced uncertainties. Exposure to local and global projects across continents and varying products, processes has helped our engineering teams to develop skills and standardise development activities. This has helped the R&D centre face the pandemic. Local market demands drive the need for building competencies locally. For example, a manual transmission will last longer in India than in other countries. This makes India, and hence Chennai, the ideal centre to grow dry friction development – for Indian and for Global needs.

Q. How has your exposure to the OE and aftermarket changed over the last five to eight quarters? What is the revenue mix?

A. Valeo has been a strong player in the aftermarket since 2012 and the business has been consistently growing with double-digit Compounded Annual Growth Rate (CAGR) for the last four years. Covid-19 pandemic and the lockdowns had resulted in a slowdown in the automotive market in 2020 both in the OE and aftermarket. The market is expected to recover in the coming months.

Q. What is the outlook for the foreseeable future?

A. India is already amongst the top four automotive markets in the world. Changing customer perception on safety, health and hygiene in the post-pandemic world will drive the changes in the Indian automotive industry. Two-wheelers and three-wheelers will see a rapid shift towards electrification in the next five years. In passenger vehicles, ICE will continue to coexist with EVs for some time, but with additional measures including hybridisation – increasing their efficiency and reducing emissions. This will give the space for homogeneous transformation in the industry – ICE to EV transformation.

Increased awareness on safety and increasing regulatory demands will necessitate the growth of active safety functions including Advanced Driver Assistance Systems (ADAS) and the drive monitoring systems. Overall, in the next decade, we will see a major transformation in the automotive industry, which will be greener, safer and smarter. We will also see many new segments emerge for the first and last mile connectivity and delivery. ACI

“Valeo is committed to achieving carbon neutrality by 2050 and reach 45 per cent of its objective by 2030. In concrete terms, this means that by 2030 we will have nearly halved our carbon footprint across our entire value chain.”

“Increasing emission norms, reduction in packaging space and higher engine speeds in passenger and commercial vehicle applications demand high burst, stable friction at elevated temperatures and low-density clutch facings.”

“Exports have grown significantly in 2020 for us despite the Covid19 pandemic, which has contributed to the revenues for Indian operations.”

“Increased awareness on safety and increasing regulatory demands will necessitate the growth of active safety functions including Advanced Driver Assistance Systems (ADAS) and the drive monitoring systems.”

Leave a Reply