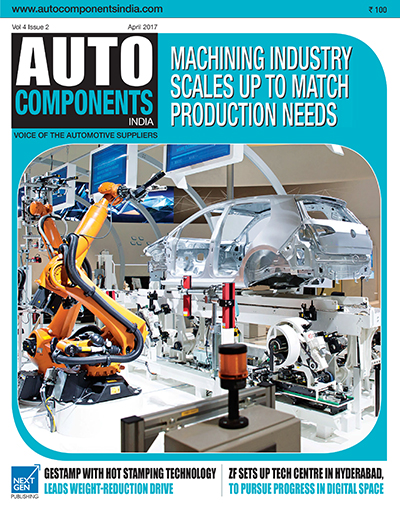

Industrial manufacturing companies are facing strong demand to increase their productivity by creating smart factories and smart manufacturing sites. The old method of manufacturing is gone and we are in the new era of manufacturing components. The factories of the near future are evolving into “smart factories”, in which networked machines constantly talk to each other. These developments are enabling manufacturers to respond to sudden changes in demand ever more rapidly – and even manufacture micro-batches of tailor-made products cost-efficiently.

To address these challenges, ‘Industry 4.0’ is the buzzword used to describe the next industrial revolution. We are currently living through the most exciting, densely packed period in the history of business and technology. The growth of automotive industry in India is the primary growth driver for the machinery industry. The automotive and auto components industry has accounted for about 40% of machine tools consumption in India. There is a positive sentiment in almost all manufacturing segments. This enthuses people to invest more and gives an opportunity for India to become a global manufacturing hub. India is already the automotive export hub in the South Asian region for some of the major auto OEMs like Hyundai, Ford, Isuzu, Suzuki, Honda, BMW, Mercedes-Benz, and Fiat.

The machine tools industry in India is highly fragmented with the presence of numerous small, medium, and large suppliers, which includes international and regional players. The providers in this market compete on the basis of product differentiation, service portfolio, and pricing. The intense competition among the vendors has resulted in increased investment in R&D and implementation of high technology solutions in machine tools. The machine tool industry is key to the government’s flagship ‘Make in India’ and ‘Skill India’ initiatives.

The machining and machinery industry is closely tied to economic conditions. An economic downturn usually translates into slowdown in this industry, and as the economy improves there typically are delays before machine tool shipments and employment trends reflect the improvement. How will this next wave of industrial evolution play out? Will it create or destroy jobs? How will job profiles evolve? And what types of skills will be in demand? The answers to these questions are critical as they seek to take full advantage of the opportunities arising from Industry 4.0 by ensuring that an appropriately skilled workforce is in place to capture them.

Hope you find this issue interesting. Looking forward to your feedback.

Bhargav TS

Executive Editor

s.bhargav@nextgenpublishing.net

Leave a Reply